Preparation method of composite lithium iron phosphate material

A technology of lithium iron phosphate and slurry, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of easy oxidation of ferrous iron, limit application, and hinder the process of industrialization, so as to achieve industrial production and process reliability. The effect of high repeatability and improved high-magnification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

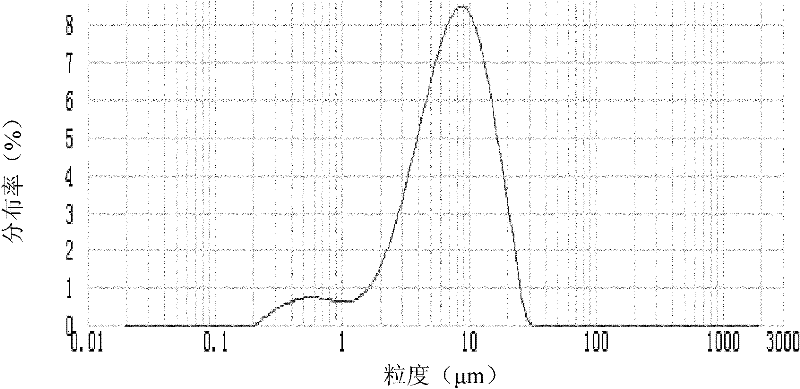

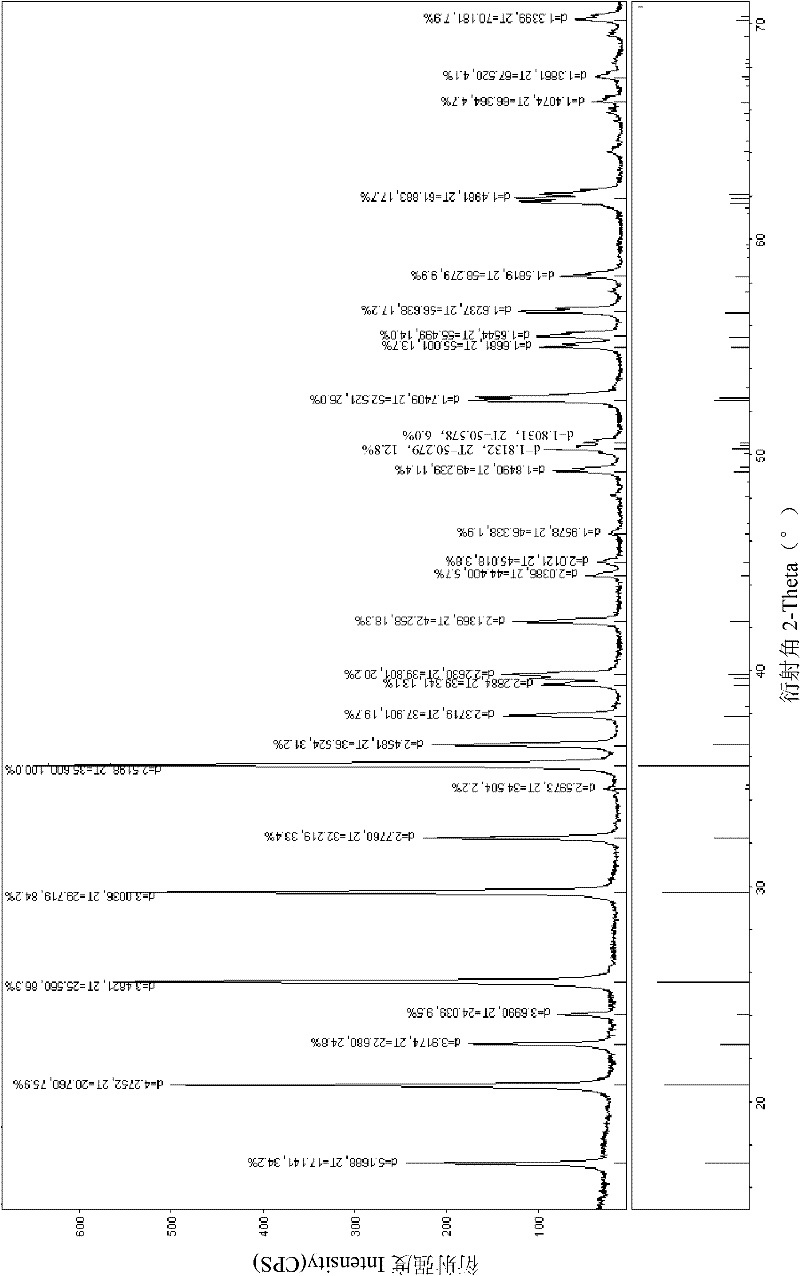

[0023] 1.98mol Fe(NO 3 ) 3 , 2mol LiH 2 PO 4 , 0.01TiO 2 , 0.01MnO 2 , 4mol citric acid was added to the pressure cooker, and then 40% deionized water was added, argon was passed and the pressure was kept at 0.1 MPa, and the stirring was continued at 120° C. for 3 hours, so that the raw materials were fully reacted and mixed uniformly. After the reaction, cool down to room temperature naturally, take out the gas and place it in a tray, dry it in a blast drying oven at 100°C, and pass it through a 100-mesh sieve. A pit furnace is used for sintering, and the obtained materials are placed in a special tank, vacuumed and filled with argon, and kept ventilated during the sintering process. The heating rate is 5°C / min, the temperature is raised to 300°C, the temperature is kept for 5h, and naturally cooled to After room temperature, take out through a 200-mesh sieve. Finally, put the sieved primary sintered material in the well-type furnace, vacuumize and fill with argon, and ...

Embodiment 2

[0025] 1.98mol Fe(NO 3 ) 3 , 2mol LiH 2 PO 4 , 0.01Y 2 o 3 , 4mol citric acid was added to the pressure cooker, and then 30% deionized water was added, argon was passed and the pressure was kept at 0.2MPa, and the stirring was continued at 120° C. for 5 hours, so that the raw materials were fully reacted and mixed uniformly. After the reaction, cool down to room temperature naturally, take out the gas and place it in a tray, dry it in a blast drying oven at 100°C, and pass it through a 100-mesh sieve. A pit furnace is used for sintering, and the obtained materials are placed in a special tank, vacuumed and filled with argon, and kept ventilated during the sintering process. The heating rate is 5°C / min, the temperature is raised to 300°C, the temperature is kept for 5h, and naturally cooled to After room temperature, take out through a 200-mesh sieve. Finally, place the sieved primary sintered material in a well-type furnace, vacuumize and fill with argon, and keep ventil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com