Carbon-supported porous spherical MoN formed by nanosheets, and application of porous spherical MoN as negative material in lithium batteries

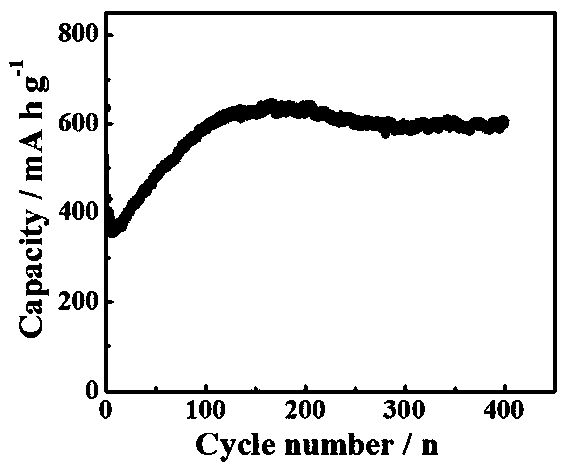

A technology of porous spherical and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of good reproducibility, good cycle stability, and good high-rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

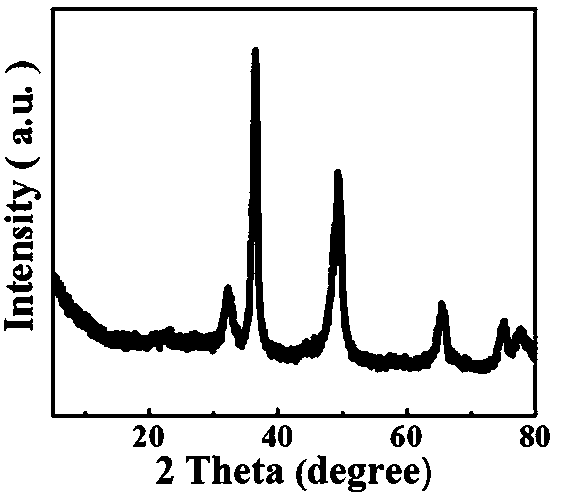

[0016] A carbon-supported porous spherical MoN composed of nanosheets, the preparation method comprising the following steps: 0.1g MoO 2 (acac) 2 , 0.2g CH 4 N 2 Put S and 0.1g glucose into 20ml H 2 O and stirred for 1 hour, then put it in an oven at 200 °C for 12 hours, took it out, waited for it to cool to room temperature, centrifuged the product, washed it with ethanol and deionized water several times, and dried it in an oven at 70 °C to obtain MoN. The precursor was then put into a tube furnace and calcined at 800 °C for 4 hours in an ammonia atmosphere to obtain a carbon-supported porous spherical MoN material composed of nanosheets.

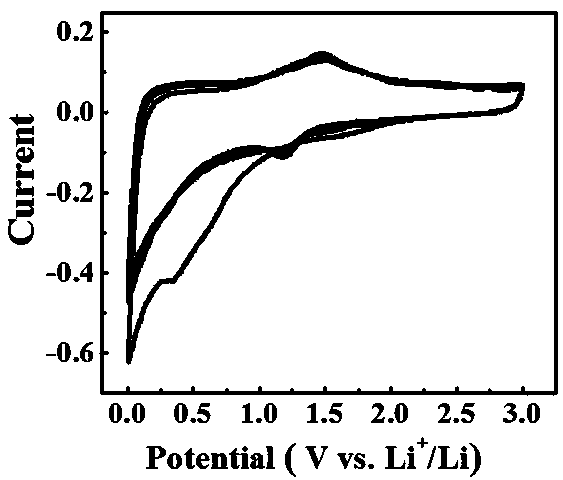

[0017] The application of the MoN as the negative electrode material in the lithium ion battery, the preparation method of the lithium battery: by mass ratio MoN nanosheet: acetylene black: polyvinylidene fluoride = 8:1:1 mixed evenly and coated on the copper foil As the negative electrode, the reference electrode and the counter elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com