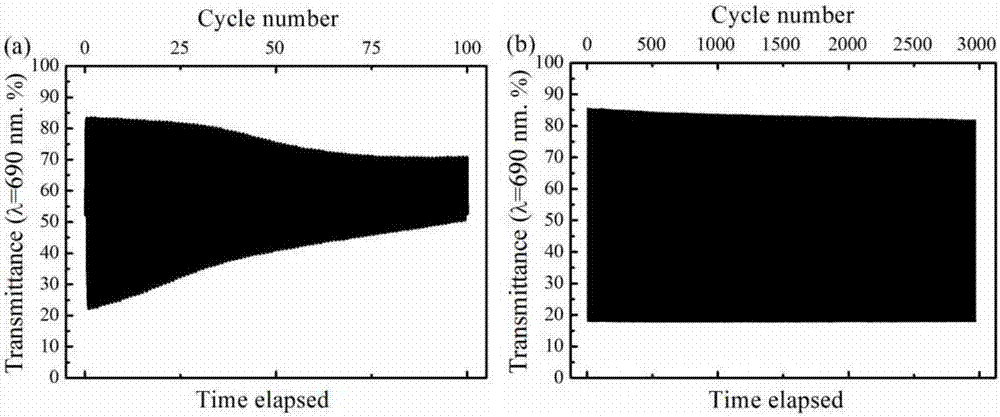

Method for improving cycling stability of prussian-blue electrochromic film in LiClO4/PC electrolyte

A cycle stability, electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of cycle stability, poor durability, poor cycle stability, can not meet the application and other problems, achieve long life, transmittance Stable, good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] (1) Prepare the PB precursor solution required for electrodeposition: mix 0.05mM K 3 Fe(CN) 6 , 0.05mM FeCl 3 . Dissolve 0.1M KCl in deionized water, stir magnetically for 5 minutes, adjust the pH to 2.0 with concentrated hydrochloric acid, and stir magnetically for 5 minutes.

[0013] (2) ITO conductive glass needs to be cleaned by acetone, ethanol and deionized water in sequence before use, and the glass should be wiped dry after cleaning. Use a potentiostat for coating, in constant current mode, use a three-electrode system for electrodeposition, ITO conductive glass to connect the working electrode, use platinum as the counter electrode, and Ag / KCl electrode as the reference electrode, at a current density of 10μA / cm 2 The electrodeposition time under the condition is 15min. The working electrode and the counter electrode are arranged in parallel and symmetrically.

[0014] (3) Rinse the deposited film with deionized water and place it in air at room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com