Method for measuring a degree of homogeneity of oils using reverse titration and measuring apparatus using the same

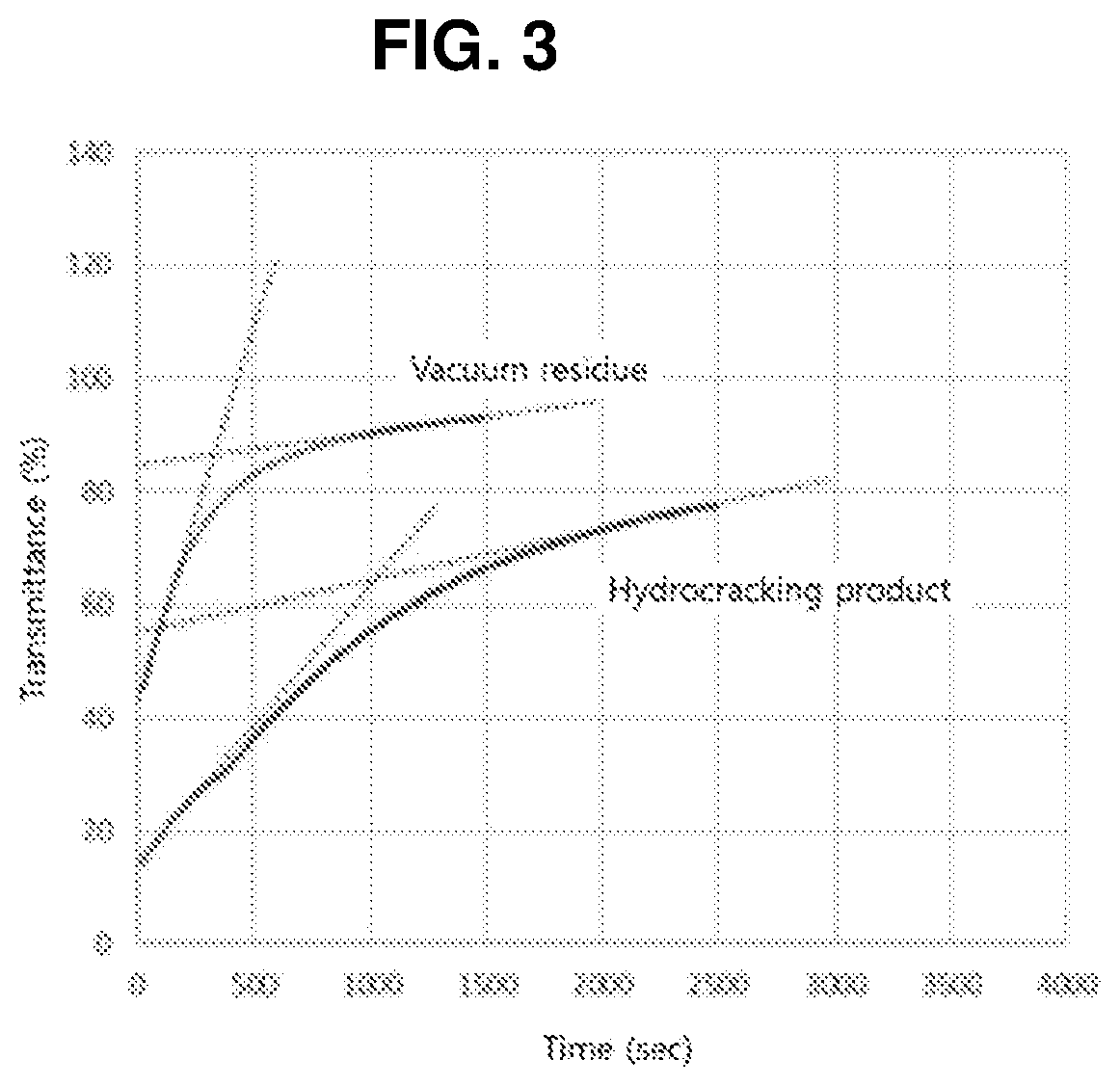

a technology of reverse titration and oil, which is applied in the direction of sedimentation settling tanks, instruments, separation processes, etc., can solve the problems of reduced miscibility, processing problems, processing problems, etc., and achieve the effect of stabilizing the uv transmittan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]Hereinafter, the present disclosure will be described in more detail. However, the present disclosure may be embodied in a variety of different forms, and the scope of the present disclosure is not limited by the embodiments described herein and should be defined only by the appended claims.

[0033]In addition, terms used in the present disclosure are used only to describe specific embodiments, and are not intended to limit the present disclosure. Singular expressions include plural expressions unless specified otherwise in the context thereof. Throughout the present specification, “including” a certain component means further including other components rather than excluding other components unless otherwise specified.

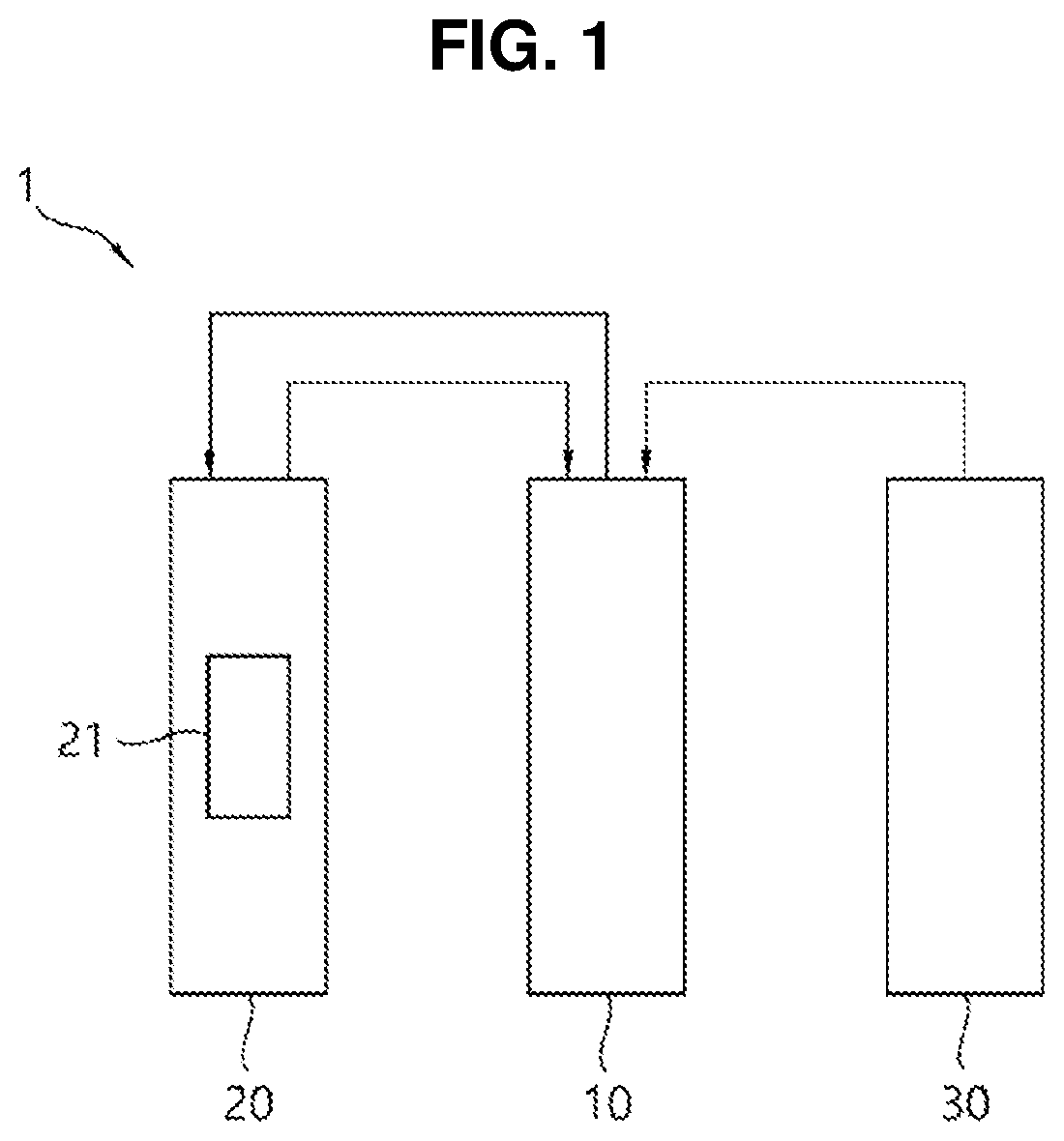

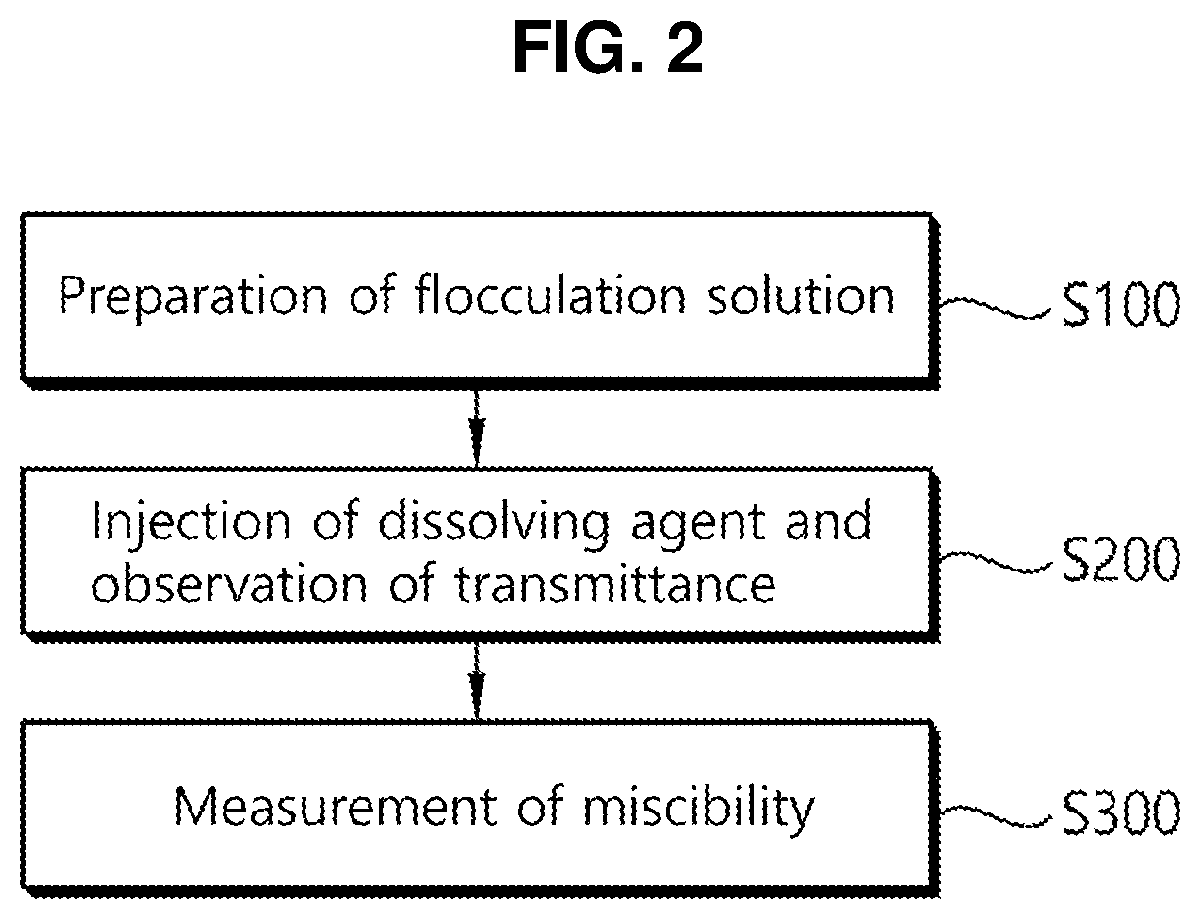

[0034]A first aspect of the present disclosure provides an apparatus for measuring miscibility in oil using back titration, the apparatus including: a flocculation solution storage unit; a flow cell including a UV transmitting member; a dissolving agent storage uni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filter size | aaaaa | aaaaa |

| miscibility | aaaaa | aaaaa |

| flocculation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com