Preparation method for improving potential of lithium ion battery positive electrode material LiCoO2

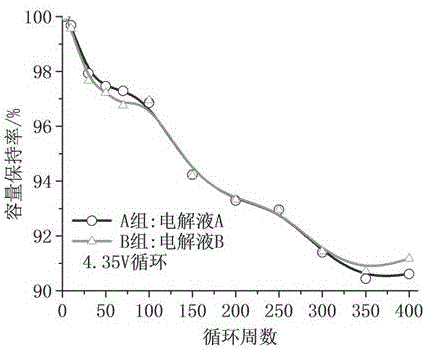

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of superior electrochemical comprehensive performance, superior cycle performance, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

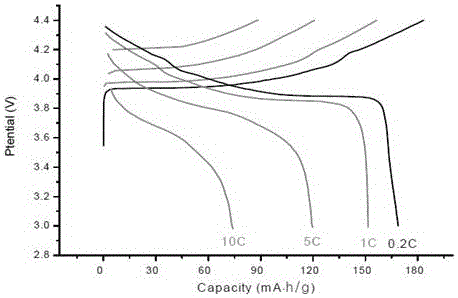

AI Technical Summary

Problems solved by technology

Method used

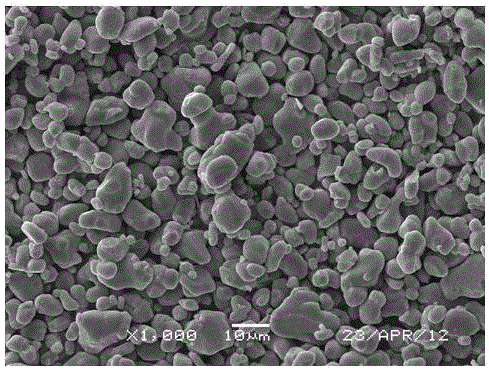

Image

Examples

Embodiment 1

[0021] A preparation method for improving the potential of lithium-ion battery cathode material LiCoO2 is completed according to the following steps:

[0022] 1. Select battery-grade lithium carbonate from Sichuan Tianqi Lithium Industry Co., Ltd. and GB-100 model cobalt tetroxide from Ningbo Kebot Cobalt and Nickel Co., Ltd. as raw materials, and make a ratio according to the molar ratio of lithium to cobalt 1.035:1. Add TiO 2 , ZrO 2 and Nb 2 o 5 As additive T1, where TiO 2 The added weight is 0.12% of the weight of tricobalt tetroxide, ZrO 2 The added weight is 0.1% of the weight of tricobalt tetroxide, Nb 2 o 5 The added weight of is 0.15% of the weight of tricobalt tetroxide. The battery grade lithium carbonate, GB-100 type cobalt tetroxide and TiO 2 , ZrO 2 and Nb 2 o 5 Perform doping and mixing, and mix well.

[0023] 2. Put the homogeneously mixed material obtained in step 1 into a refractory sagger, push it into a high-temperature pusher kiln, keep it w...

Embodiment 2

[0029] A preparation method for improving the potential of lithium-ion battery cathode material LiCoO2 is completed according to the following steps:

[0030] 1. Select battery-grade lithium carbonate from Sichuan Tianqi Lithium Industry Co., Ltd. and GB-100 model cobalt tetroxide from Ningbo Kebot Cobalt and Nickel Co., Ltd. as raw materials, and make a ratio according to the molar ratio of lithium to cobalt 1.05:1. Add TiO 2 , CeO 2 and Nb 2 o 5 As additive T1, where TiO 2 The added weight is 0.12% of the weight of tricobalt tetroxide, CeO 2 The added weight is 0.15% of the weight of tricobalt tetroxide, Nb 2 o 5 The added weight is 0.1% of the weight of tricobalt tetroxide. The battery grade lithium carbonate, GB-100 type cobalt tetroxide and TiO 2 , CeO 2 and Nb 2 o 5 Perform doping and mixing, and mix well.

[0031] 2. Put the homogeneously mixed material obtained in step 1 into a refractory sagger, push it into a high-temperature pusher kiln, keep it warm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compaction density | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com