Titanium-series cathode active material and preparation method thereof, titanium-series lithium ion power battery

A technology of negative electrode active material and power battery, which is applied in the field of titanium series negative electrode active material and its preparation, and titanium series lithium ion power battery field, can solve the problems of poor product consistency, no charging end indication, low volume specific capacity, etc. The effect of wide temperature range, good battery processing performance and high volume specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of the titanium-based negative electrode active material of the present invention comprises the following steps:

[0031] 1. According to the molar ratio of lithium in inorganic lithium salt: titanium dioxide: doping modifier: 1.9-2.1: 4.9-5.1: greater than 0-10, after mixing, use high-speed stirring or ball milling method, speed 100-500r / min, grind Disperse for 2 to 40 hours to prepare a composite lithium titanate precursor mixture, that is, Li 4 Ti 5 o 12 with M x Inorganic lithium salts are lithium hydroxide, lithium carbonate, lithium acetate, lithium chloride, lithium sulfate, lithium nitrate, lithium iodide, lithium tert-butoxide, lithium benzoate, lithium formate, lithium fluoride, lithium chromate , lithium citrate tetrahydrate, lithium tetrachloroaluminate, lithium bromide, lithium tetrafluoroborate or lithium oxalate, the doping modifier is metal element Al, Mg, Cu, Ag, Ni, Co, Mn, Cd, Pb, Bi , Sn, Ge, metal compounds alumina, magnes...

Embodiment 1

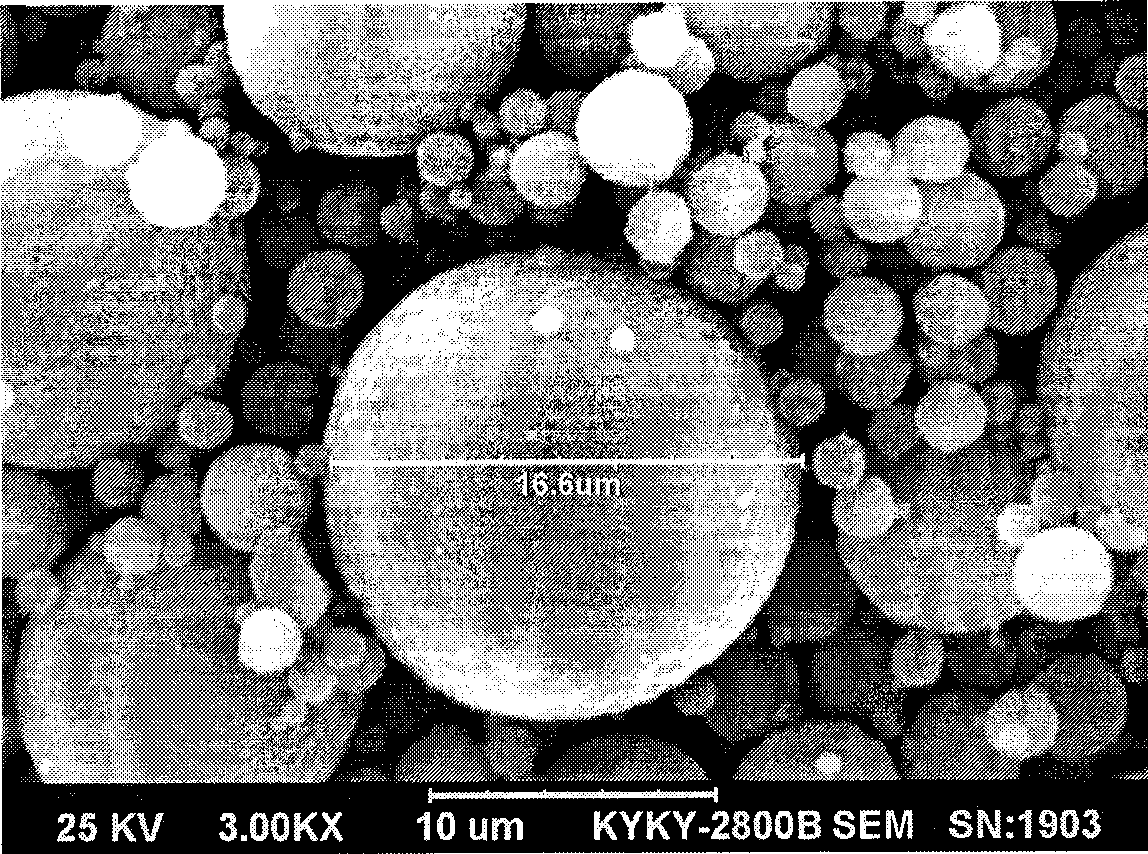

[0037] Example 1: 2mol of lithium carbonate, 5mol of titanium dioxide, 0.1mol of nano-sized copper oxide powder, 4mol of nano-carbon, and a rotation speed of 300r / min were ground and dispersed for 16 hours to obtain a composite lithium titanate precursor mixture; the composite lithium titanate precursor mixture Disperse in ethanol, the ratio of solid to organic solvent is 1.5:1, and spray dry at 150°C to obtain dispersed powder; heat-treat the dispersed powder at a heating rate of 5°C / min in a temperature range of 700°C For 24 hours, nitrogen gas was introduced during the period, and naturally cooled to below 150 ° C; crushed and sieved to obtain Li with an average particle size of 10 μm 4 Ti 5 o 12 / CuO 0.1 (x=0.1) negative electrode active material. Such as figure 1 As shown, the lithium titanate material has spherical and spheroidal microscopic features, and the surface is smooth, such as Figure 6 As shown, the thickness of the nano-coating layer is about 8nm, and the...

Embodiment 2

[0040] Example 2: 2.1mol of lithium carbonate, 5.1mol of titanium dioxide, and 0.1mol of nano-scale alumina powder were ground and dispersed for 24 hours at a speed of 200r / min to prepare a composite lithium titanate precursor mixture; the composite lithium titanate precursor mixture was dispersed in In ethanol, the ratio of solid to organic solvent is 1.5:1, and the dispersed powder is obtained by spray drying at 250°C; the dispersed powder is heat-treated at a temperature of 400°C for 40 hours at a heating rate of 10°C / min , during which nitrogen gas was introduced, naturally cooled to below 150°C; crushed and sieved to obtain Li with an average particle size of 1 μm 4 Ti 5 o 12 / (Al 2 o 3 ) 0.1 (x=0.1) negative electrode active material.

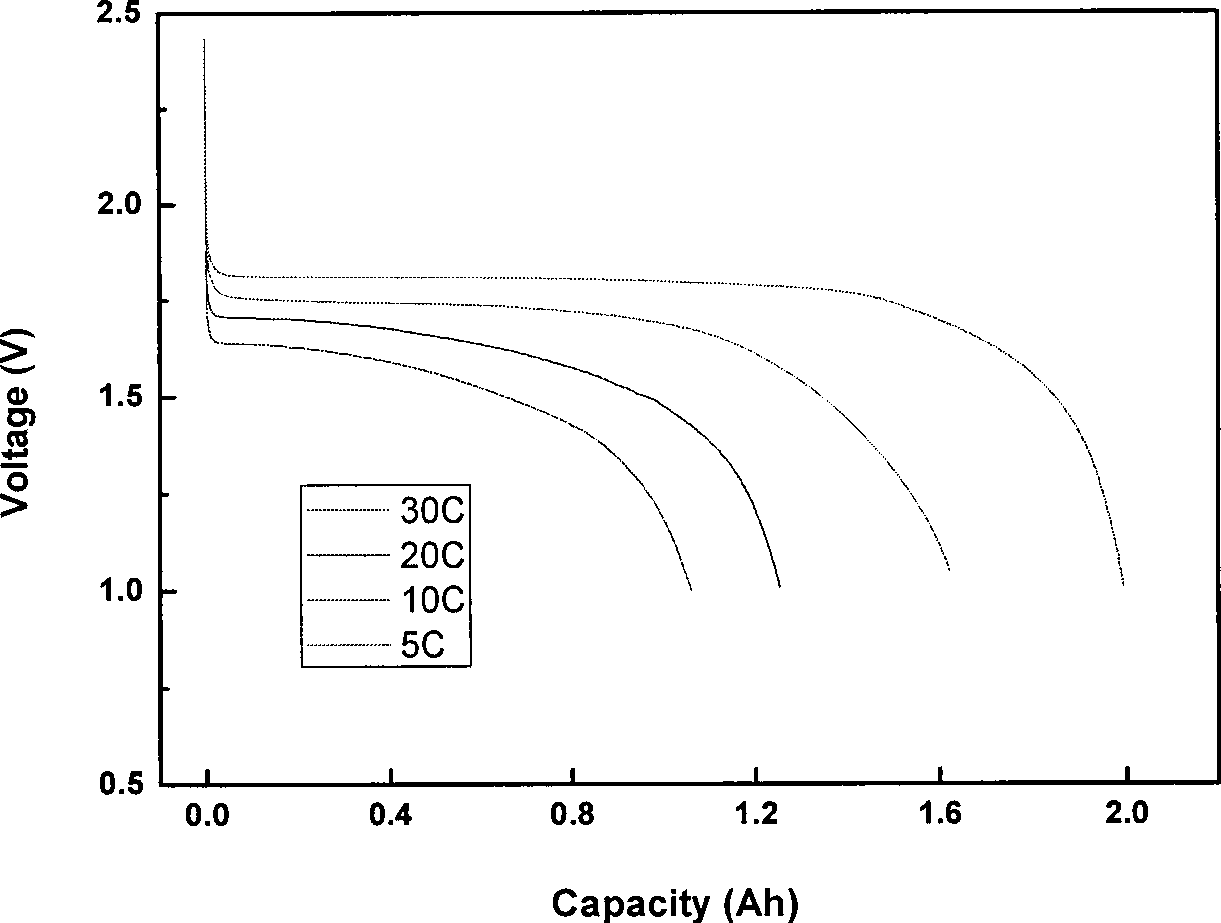

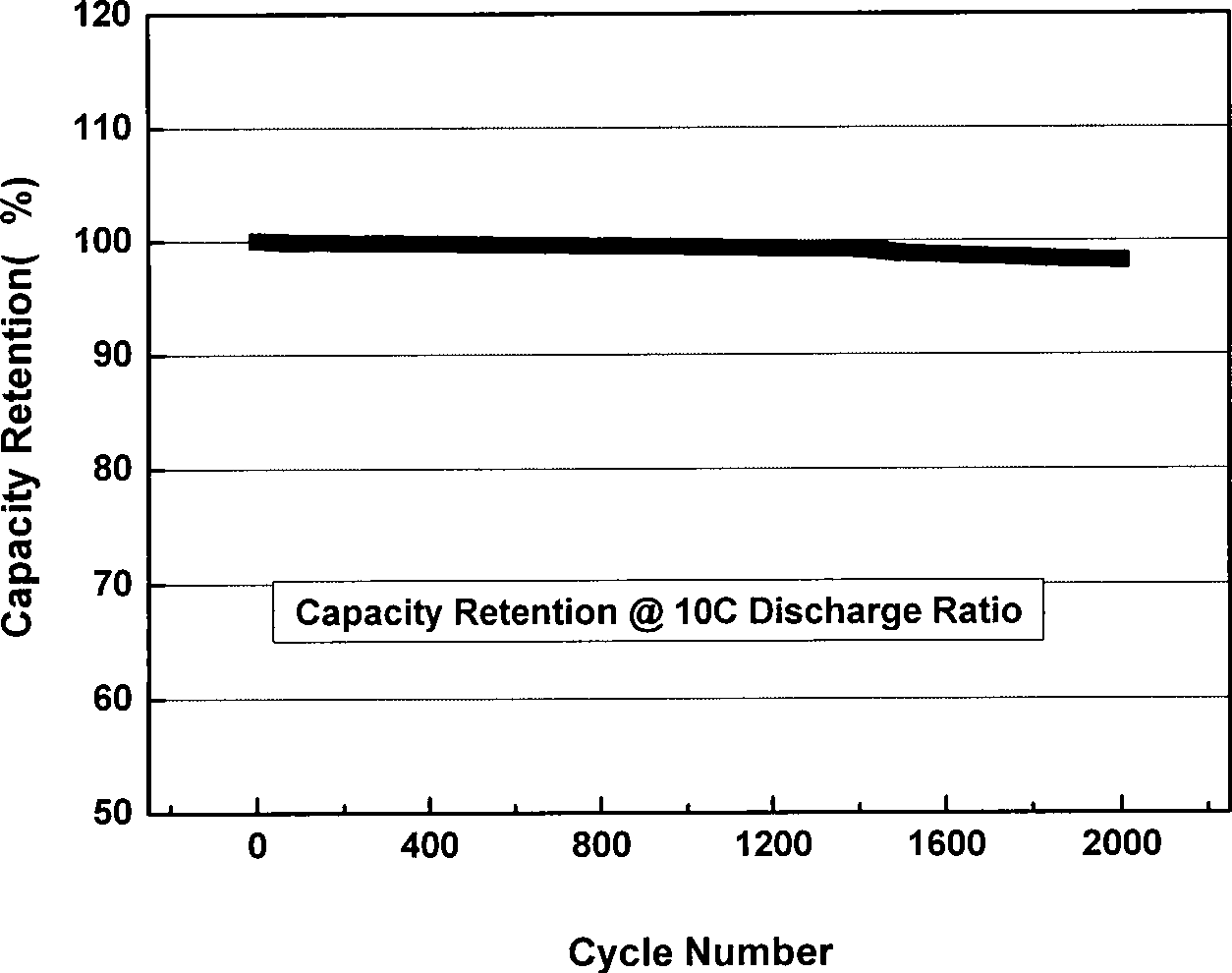

[0041] The negative electrode active material obtained above, the conductive agent acetylene black, and the binder PVDF are used in a mass ratio of 85%:10%:5% to make a negative electrode sheet. LiFePO 4 , Conductive agent acetylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com