Metal doped and Mxene coated double modified lithium iron phosphate composite material, and preparationmethodand application

A technology of lithium iron phosphate and composite materials, applied in chemical instruments and methods, phosphorus compounds, non-metallic elements, etc., can solve the problem of poor electronic conductivity and ion conductivity, poor cycle performance and rate performance, and small diffusion coefficient of lithium ions and other problems, to achieve the effect of good uniformity, high specific surface area, good conductivity and hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

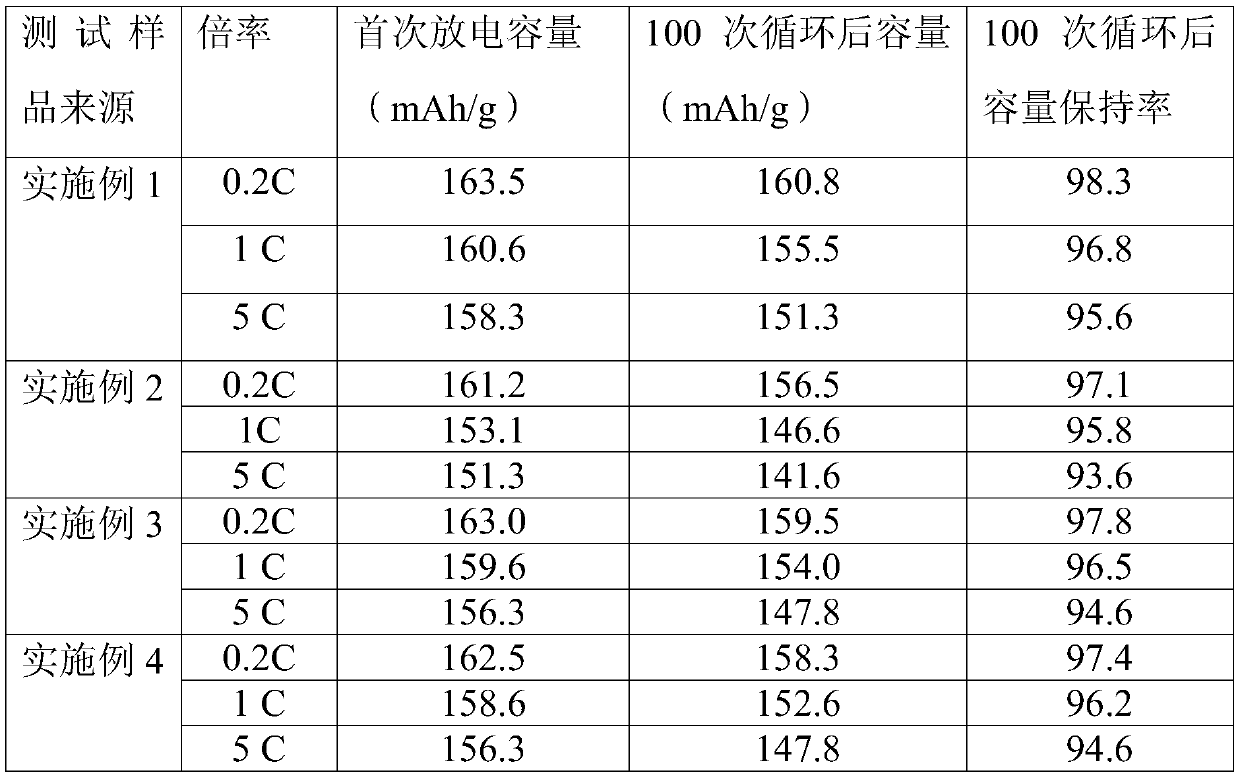

Examples

Embodiment 1

[0036] (1). Put Ti 3 C 2 Put it in a furnace and heat it at 200°C for 1.5min, then cool it down to room temperature naturally to get TiO 2 / Ti 3 C 2 composite materials;

[0037] (2). 1.0mol / L ferrous oxalate (the added volume is 0.75L), 2.0mol / L ammonium dihydrogen phosphate, 4.0mol / L LiOH according to the molar ratio of iron element, phosphate radical and lithium element is 1 :1.2:1.05 were placed in the reactor in turn, stirred at 100r / min for 1h, then added 0.15mol Ti 3 C 2 TiO prepared by heating in step (1) 2 / Ti 3 C 2 Composite material, adjust the pH of the solution to 8. Nitrogen was introduced at a flow rate of 2L / min, and the temperature of the reactor was raised to 120°C. After reacting for 2 hours, it was cooled to room temperature, centrifuged, and dried to obtain the precursor product;

[0038] (3). The precursor product of step (2) is placed in a high-temperature furnace, and N is introduced at a flow rate of 1L / min. 2 , raise the temperature of the ...

Embodiment 2

[0040] (1). Put Ti 3 C 2 After heating at 250 °C for 5 min in a furnace, it was naturally cooled to room temperature to obtain TiO 2 / Ti 3 C 2 composite material;

[0041] (2). The 3.0mol / L ferrous oxalate (the added volume is 0.25L), 2.0mol / L ammonium dihydrogen phosphate, and 4.0mol / L LiOH are 1 according to the molar ratio of iron, phosphate and lithium. : 1.2: 1.05 were placed in the reactor in turn, stirred at 100r / min for 30min, and then added 0.4mol Ti 3 C 2 TiO prepared by heating in step (1) 2 / Ti 3 C 2 composite material, adjust the pH of the solution to 8, introduce nitrogen gas, heat the reaction kettle to 120°C, react for 2 hours, cool to room temperature, centrifuge, and dry to obtain the precursor product;

[0042] (3). The precursor product of step (2) is placed in a high-temperature furnace, and N is fed at a flow rate of 1 L / min. 2 , the high temperature furnace was heated to 550 °C for 6 hours of high temperature sintering, cooled down, and cooled ...

Embodiment 3

[0044] (1). Zr 3 C 2 After heating at 200°C for 1.5min in a furnace, it was naturally cooled to room temperature to obtain ZrO 2 / Zr 3 C 2 composite material;

[0045] (2) 2.0mol / L ferrous oxalate (the added volume is 0.5L), 2.0mol / L ammonium dihydrogen phosphate and 4.0mol / L lithium acetate are 1 according to the molar ratio of iron element, phosphate group and lithium element :1.1:1.1 were placed in the reactor in turn, stirred at 120r / min for 3h, and then added 0.1mol Zr 3 C 2 ZrO prepared by heating in step (1) 2 / Zr 3 C 2 composite material, adjust the pH of the solution to 8, introduce nitrogen at a flow rate of 2L / min, heat the reaction kettle to 120°C, react for 2h, cool to room temperature, centrifuge, and dry to obtain the precursor product;

[0046] (3). The precursor product of step (2) is placed in a high-temperature furnace, and N is fed at a flow rate of 1 L / min. 2 , the high-temperature furnace was heated to 550 °C for 6 hours of high-temperature sint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com