Lithium ion battery cathode material as well as preparation method and applications thereof

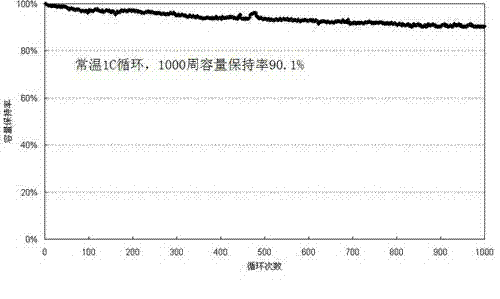

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, carbon preparation/purification, circuits, etc., can solve problems such as difficulty in industrialized production, low temperature performance and specific capacity of materials, and cumbersome preparation and operation process. , to achieve the effect of enhancing lithium storage capacity, excellent high-rate performance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

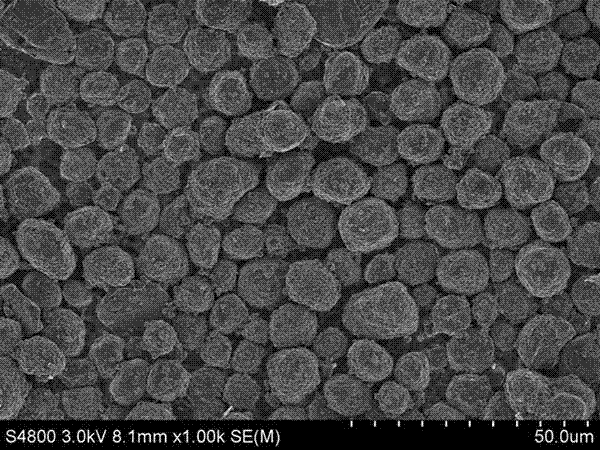

[0050] Example 1 Preparation of anode material for lithium ion battery

[0051] The method for preparing the negative electrode material of the lithium ion battery in this embodiment includes the following steps:

[0052] (1) Preparation of mesophase spheres

[0053] Weigh 900g of medium-temperature petroleum pitch and 100g of cobalt nitrate, add them to the reaction kettle, stir until the mixture is uniform, heat up to 400°C at a rate of 2°C / min, and hold at a constant temperature of 10Mpa for 5 hours for thermal polycondensation reaction. Obtain a reaction mixture mother liquor containing mesophase spheres;

[0054] (2) Low temperature carbonization treatment of mesophase spheres

[0055] Add 2kg of washing oil to the reaction mixture mother liquor obtained in step (1), stir and wash for 2 hours, after centrifugal separation, the mesophase spheres are obtained. Under the protection of nitrogen, the mesophase spheres are carbonized at 800°C for 8 hours, and the temperature ...

Embodiment 2

[0058] Example 2 Preparation of anode material for lithium ion battery

[0059] The method for preparing the negative electrode material of the lithium ion battery in this embodiment includes the following steps:

[0060] (1) Preparation of mesophase spheres

[0061] Weigh 1000g of medium-temperature coal tar pitch and 80g of nickel nitrate into the reactor, stir until the mixture is uniform, heat up to 420°C at a rate of 2°C / min, and keep it at a constant temperature of 15Mpa for 4 hours for thermal condensation reaction to obtain The reaction mixture mother liquor of phase carbon microspheres;

[0062] (2) Low temperature carbonization treatment of mesophase spheres

[0063] Add 2.5kg of washing oil to the reaction mixture mother liquor obtained in step (1), stir and wash for 3 hours, after centrifugal separation, the mesophase spheres are obtained. Under the protection of nitrogen, the mesophase spheres are carbonized at 850°C for 6 hours. The heating rate is 5℃ / min to o...

Embodiment 3

[0066] Example 3 Preparation of anode material for lithium ion battery

[0067] The method for preparing the negative electrode material of the lithium ion battery in this embodiment includes the following steps:

[0068] (1) Preparation of mesophase spheres

[0069] Weigh 1000g of medium-temperature coal tar pitch and 80g of ferric nitrate into the reactor, stir until the mixture is uniform, heat up to 430°C at a rate of 2°C / min, and hold at a constant temperature of 20Mpa for 5 hours for thermal polycondensation reaction. The reaction mixture mother liquor of phase carbon microspheres;

[0070] (2) Low temperature carbonization treatment of mesophase spheres

[0071] Add 2.5 kg of washing oil to the reaction mixture mother liquor obtained in step (1) and wash for 3 hours. After centrifugal separation, mesophase spheres are obtained. Under the protection of nitrogen, the mesophase spheres are carbonized at 900°C for 5 hours. It is 3℃ / min to obtain mesocarbon microspheres af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com