Lithium-ion battery cathode material with long service life and high power as well as preparation method thereof

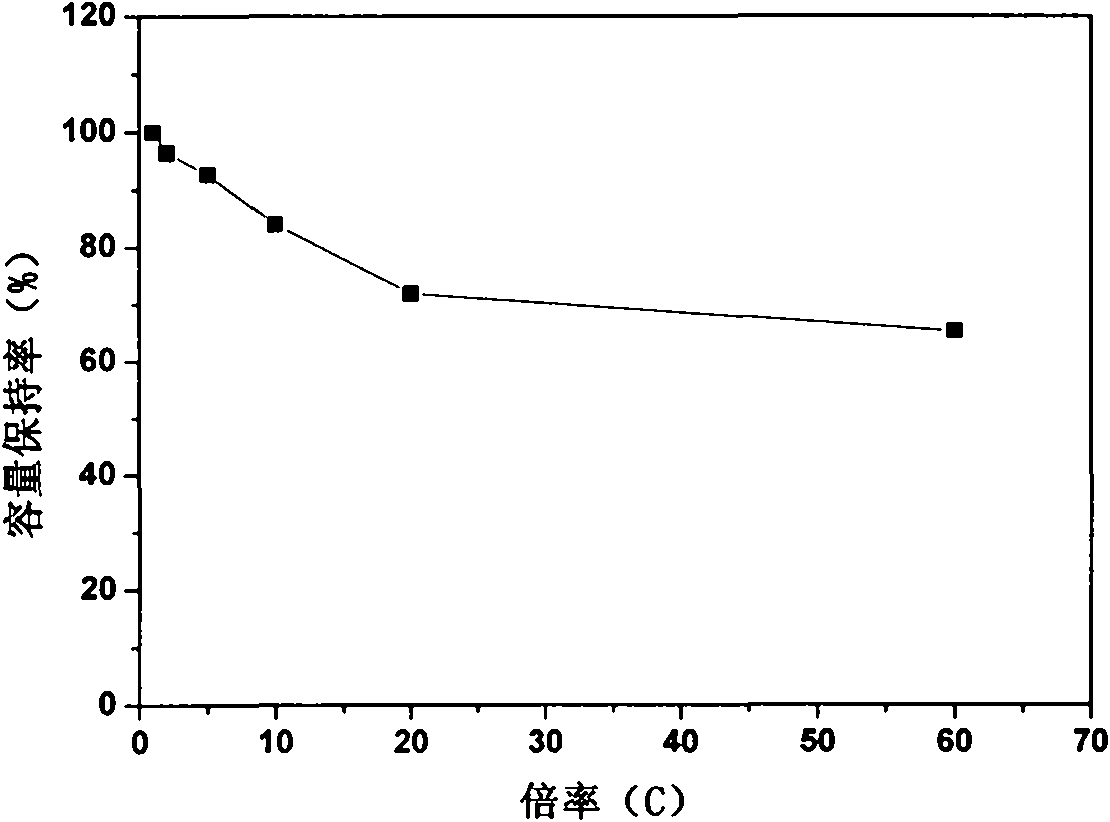

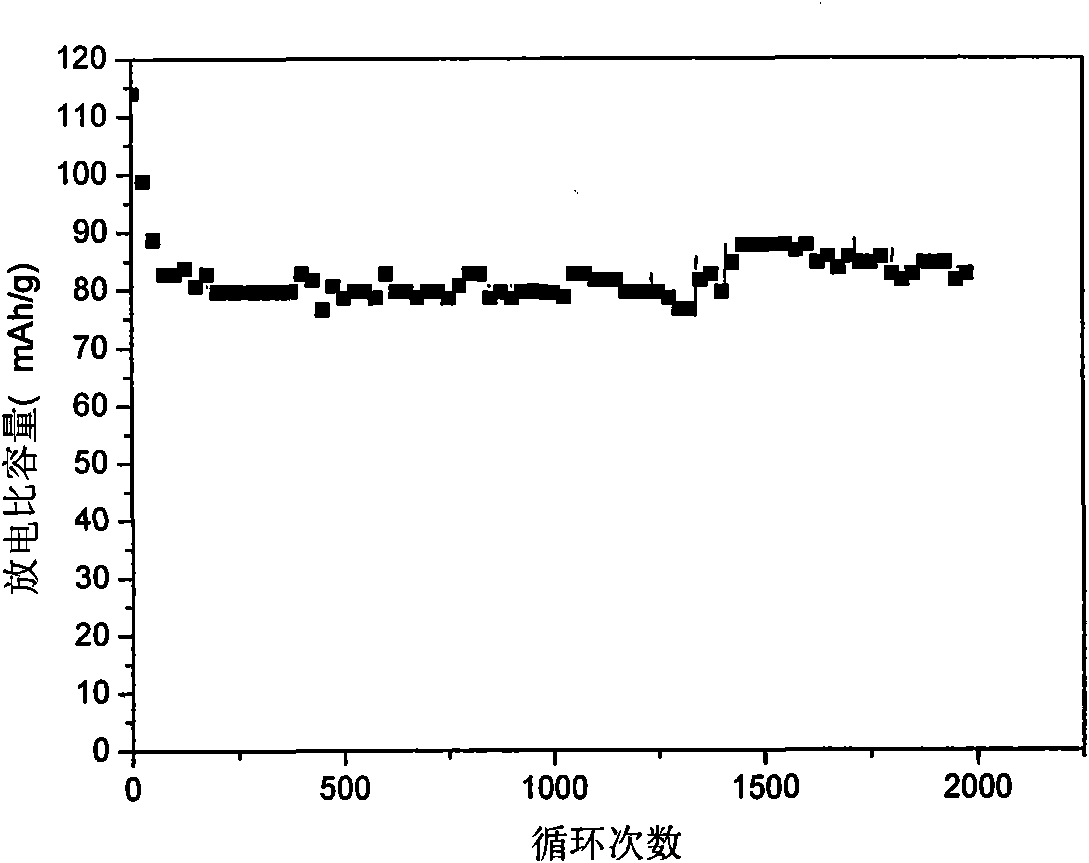

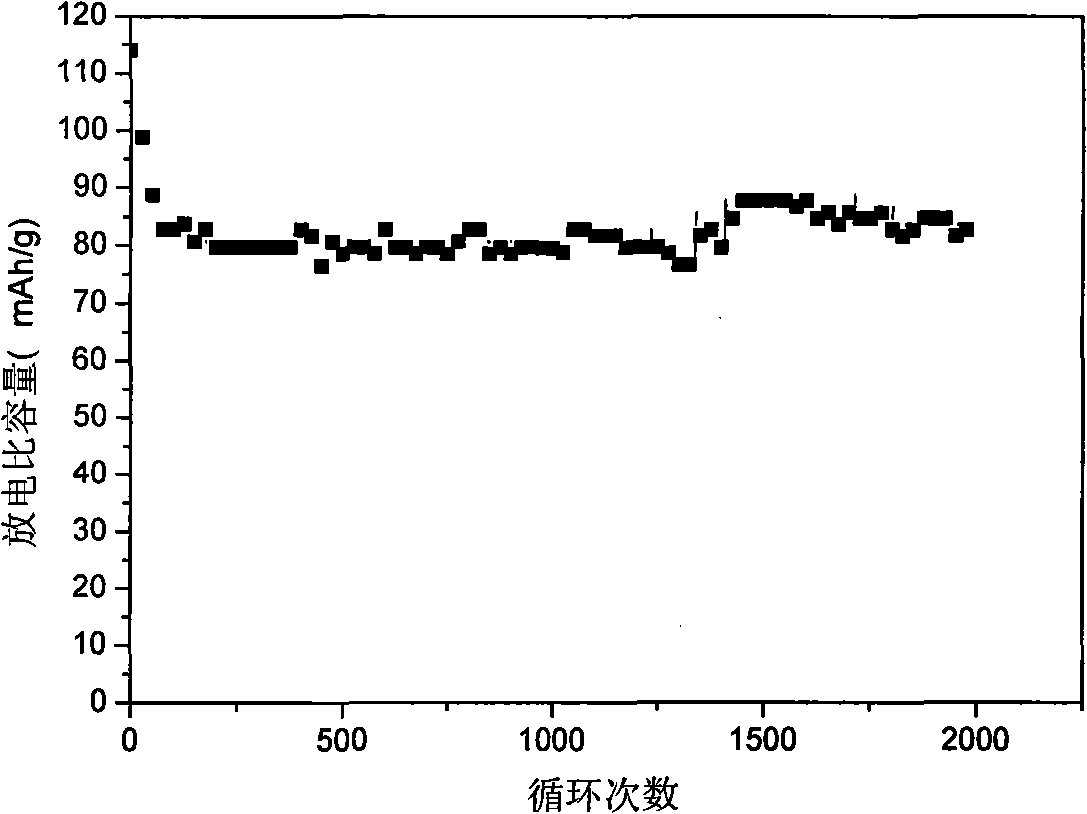

A lithium-ion battery and negative electrode material technology, applied in the field of electrochemical energy, can solve the problems of limiting material performance at large rates, low conductivity, and limited applications, achieving excellent high rate performance and cycle performance, simple preparation process, and expanded production effect of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 2

[0023] First weigh tetrabutyl titanate and lithium acetate according to the ratio of Li:Ti molar ratio of 4.2:5 and put them into a flask, add absolute ethanol and stir to mix evenly, then mix the two solutions together, magnetically stir evenly and add slowly Distilled water and glacial acetic acid, after stirring for 30 minutes, add conductive carbon black with a carbon content of 15%, continue to stir until it becomes a colloid, age for 10-20 hours, and then place it in an oven at 85°C for 10 hours. The dried solid powder is milled with a ball mill for 3 hours, taken out and placed in a tube furnace for calcination in N2 gas, the N2 gas flow is controlled at 24L / h, the heating rate is 15°C / min, the calcination temperature is 850°C, and the calcination time for 3 hours, and then naturally cooled to room temperature to obtain a Li4Ti5O12 / C composite.

[0024] The preparation of the pole piece, the assembly of the experimental battery and the electrochemical performance test a...

Embodiment example 3

[0026] First weigh tetrabutyl titanate and lithium acetate according to the ratio of Li:Ti molar ratio of 4:5 and put them into a flask, add absolute ethanol and stir to mix evenly, then mix the two solutions together, magnetically stir evenly and add slowly Distilled water and glacial acetic acid, after stirring for 30 minutes, add conductive carbon black with a carbon content of 5%, continue to stir until it becomes a colloid, age for 10 to 20 hours, and then place it in an oven at 85°C for 10 hours to dry. The dried solid powder is milled with a ball mill for 3 hours, taken out and placed in a tube furnace for calcination in N2 gas, the N2 gas flow is controlled at 24L / h, the heating rate is 15°C / min, the calcination temperature is 850°C, and the calcination time for 3 hours, and then naturally cooled to room temperature to obtain a Li4Ti5O12 / C composite.

[0027] The preparation of the pole piece, the assembly of the experimental battery and the electrochemical performance...

Embodiment example 4

[0029]First weigh tetrabutyl titanate and lithium acetate according to the ratio of Li:Ti molar ratio of 4.5:5 and put them into a flask, add absolute ethanol and stir to mix evenly, then mix the two solutions together, magnetically stir evenly and add slowly Distilled water and glacial acetic acid, after stirring for 30 minutes, add conductive carbon black with a carbon content of 20%, continue to stir until it becomes a colloid, age for 10-20 hours, and then place it in an oven at 85°C for 10 hours to dry. The dried solid powder is milled with a ball mill for 3 hours, taken out and placed in a tube furnace for calcination in N2 gas, the N2 gas flow is controlled at 24L / h, the heating rate is 15°C / min, the calcination temperature is 850°C, and the calcination time for 3 hours, and then naturally cooled to room temperature to obtain a Li4Ti5O12 / C composite.

[0030] The preparation of the pole piece, the assembly of the experimental battery and the electrochemical performance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com