Sandwich core-shell structured lithium-rich manganese base, spinel and graphene flexible composite positive electrode and production method thereof

A lithium-rich manganese-based, core-shell structure technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of low energy density, low lithium ion diffusion rate, and large irreversible capacity of lithium-rich manganese-based cathodes. Excellent high-rate performance, improved lithium ion diffusion rate, and obvious and reliable performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

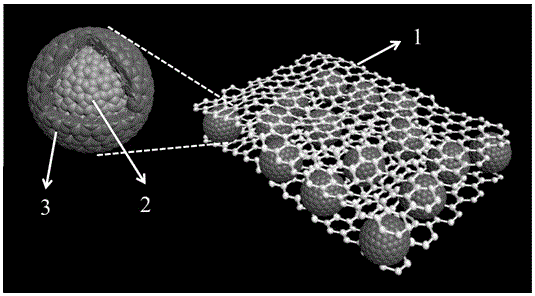

specific Embodiment approach 1

[0029] Specific embodiment one: a lithium-rich manganese-based, spinel and graphene flexible composite positive electrode with a sandwich core-shell structure, the chemical formula of the lithium-rich manganese-based positive electrode material is aLi 2 MnO 3 ·(1-a)LiMO 2 , the chemical formula of the spinel material is LiMn 2-x m x o 4 , where: 0.1≤a1-x-y Ni x co y , 0≤x≤0.5, 0≤y≤0.5.

[0030] The effect of this embodiment: improve the energy density, flexibility and plasticity of lithium-rich manganese-based positive electrodes; improve the cycle life of lithium-rich manganese-based materials; improve the diffusion rate of electrons and lithium ions in lithium-rich manganese-based materials; The improvement is obvious and reliable, and it has a large specific capacity and excellent rate and cycle performance.

specific Embodiment approach 2

[0031] Embodiment 2: A method for preparing a lithium-rich manganese-based, spinel, and graphene flexible composite positive electrode with a sandwich core-shell structure described in Embodiment 1. The method includes the following process steps:

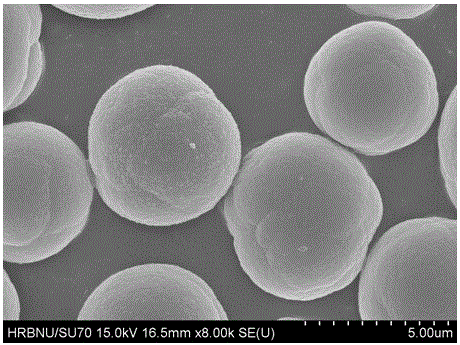

[0032] Step 1: Prepare manganese-nickel-cobalt carbonate spherical precursor by co-precipitation method;

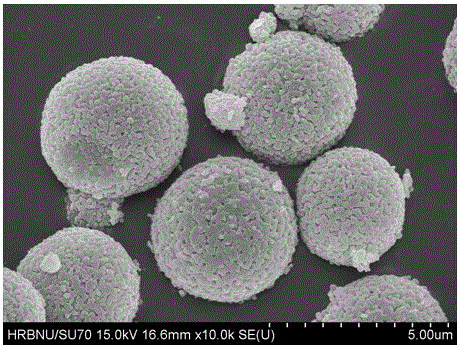

[0033] Step 2: Uniformly mixing and calcining the manganese-nickel-cobalt carbonate spherical precursor obtained in Step 1 and the lithium salt compound, so as to obtain a spherical lithium-rich manganese-based positive electrode material;

[0034] Step 3: Mix the spherical lithium-rich manganese-based positive electrode material obtained in step 2 with the graphene oxide dispersion, and prepare the mixed spherical lithium-rich manganese-based positive electrode material and the graphene oxide dispersion by vacuum filtration to have a sandwich structure Lithium-rich manganese-based and graphene oxide composite films, and final...

specific Embodiment approach 3

[0036] Specific embodiment three: the preparation method of the lithium-rich manganese-based, spinel and graphene flexible composite positive electrode of the sandwich core-shell structure described in the specific embodiment two, the specific steps of the step one are as follows:

[0037] Step (1): Weigh the manganese salt compound, nickel salt compound and cobalt salt compound respectively, and dissolve them all in deionized water and mix them evenly to prepare a mixed metal salt solution M of 0.1~1 mol / L;

[0038] Step (2): Weigh the carbonate precipitant and complexing agent respectively, dissolve them in deionized water and mix them evenly to prepare a mixed solution of carbonate precipitant and complexing agent at 0.1-1 mol / L;

[0039] Step (3): Add the prepared mixed solution of carbonate precipitation agent and complexing agent into the mixed metal salt solution M in step (1) under strong stirring to control the precipitation of mixed metal salt and carbonate The molar r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com