Composite oxidation technology for medicinal titanium alloy

A composite oxidation and titanium alloy technology, which is applied in the field of composite oxidation technology, can solve the problems of poor bonding between the oxide layer and the titanium alloy base material, affecting the biocompatibility and corrosion resistance of titanium alloys, and achieve low cost and low equipment investment. The effect of small size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

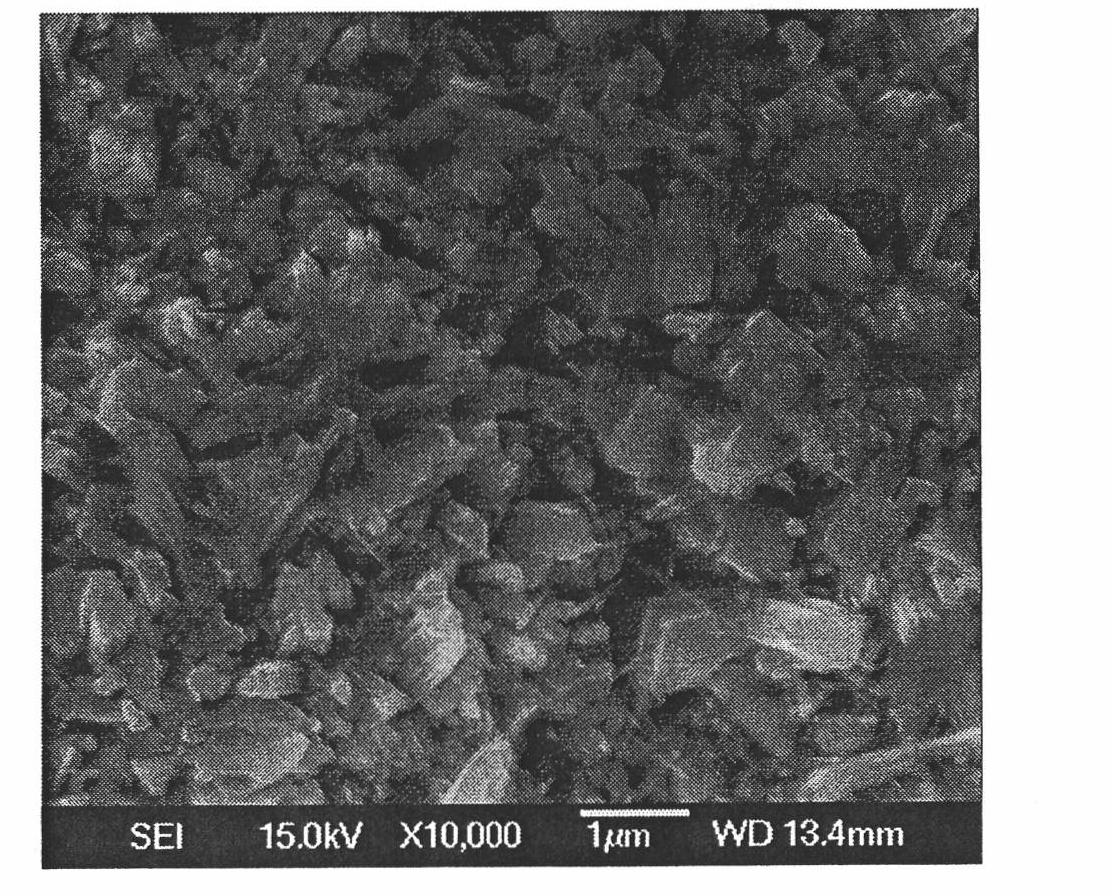

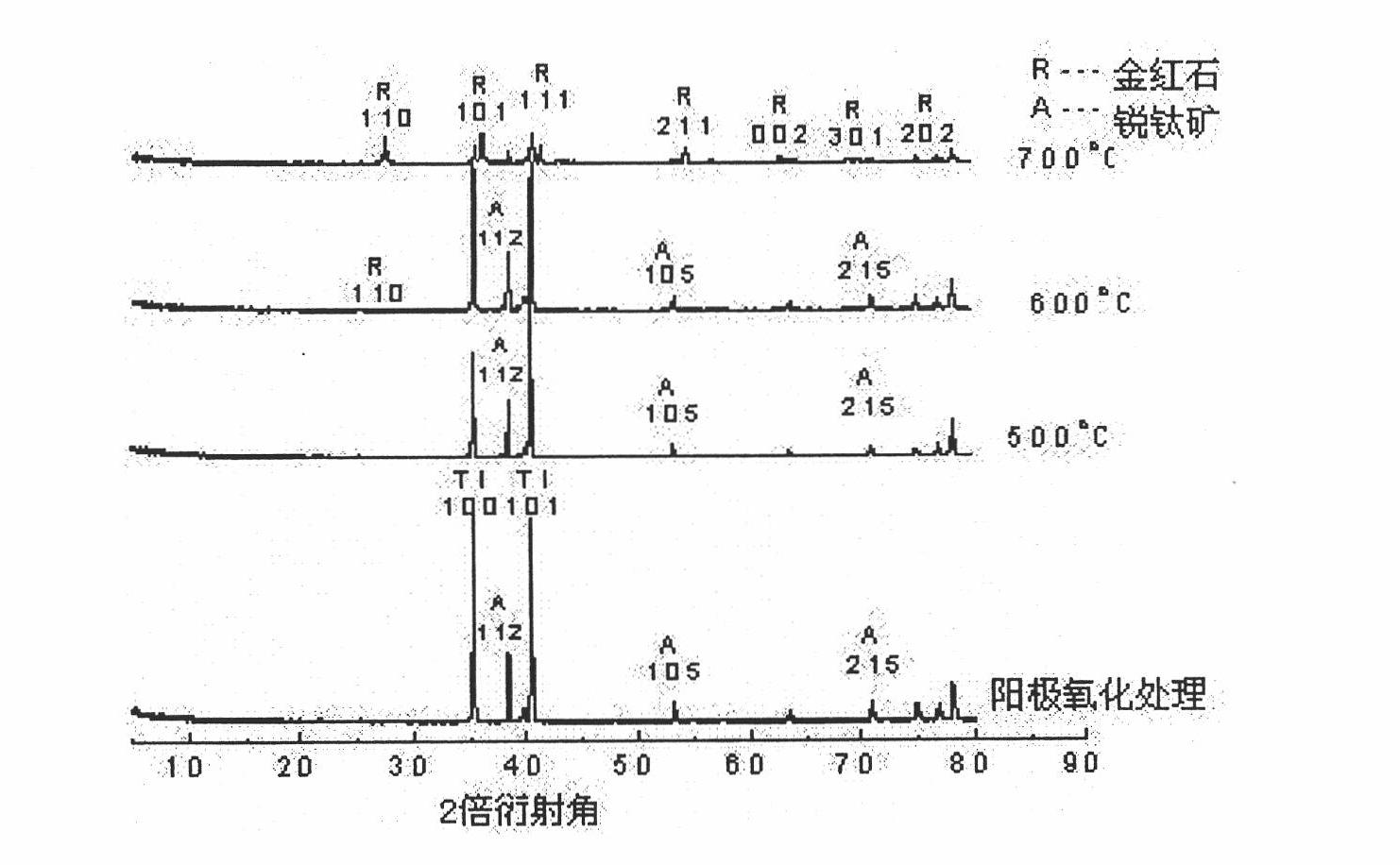

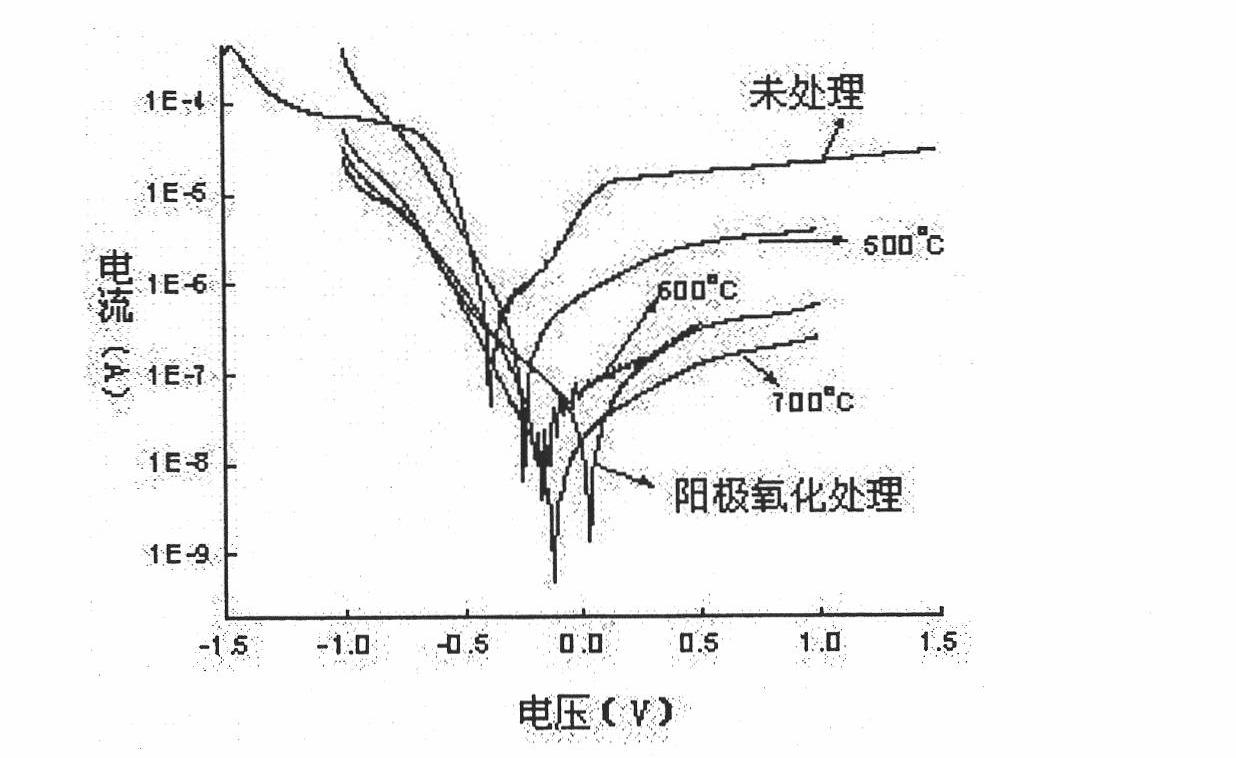

[0026] In this embodiment, medical titanium alloy (Ti-6Al-4V) is used as the base material.

[0027] Firstly, the annealed Ti-6Al-4V alloy is first mechanically polished, then polished smooth with metallographic water sandpaper (500#, 1000#, 2000#), washed with distilled water, then ultrasonically cleaned in acetone for 10 minutes, and then degreased Carry out chemical degreasing in the liquid for 10 minutes, rinse with distilled water and blow dry, and then put a certain molar ratio of NH 4 HF 2 : HNO 3 :H 2 o 2 (1:2:2) acidic solution for activation for 1min, and finally put the titanium alloy sample into the solution at a constant temperature of 25°C to form NH 4 h 2 PO 4 : 60g / L; CH 3 COONH 4 : 20g / L; H 2 o 2 : 20mL / L; sodium gluconate: 2g / L; surfactant sodium dodecylbenzenesulfonate: 2g / L; pH: 6.8 electrolyte solution as working electrode, stainless steel as auxiliary electrode, saturated calomel electrode Constitute a three-electrode system for the reference e...

Embodiment 2

[0029] In this embodiment, the medical titanium alloy bone nail is used as the base material.

[0030] Firstly, the medical titanium alloy bone nails are polished by sandblasting, cleaned with distilled water, ultrasonically cleaned in acetone for 10 minutes, then chemically degreased in a degreasing solution for 10 minutes, rinsed with distilled water and dried, and then placed in a certain molar ratio to NH 4 HF 2 : HNO 3 :H 2 o 2 (1:2:2) acidic solution for activation for 1min, and finally put the titanium alloy sample into the solution at a constant temperature of 25°C to form NH 4 h 2 PO 4 : 50g / L; CH 3 COONH 4 : 25g / L; H 2 o 2 : 20mL / L; sodium gluconate: 2g / L; surfactant sodium dodecylbenzenesulfonate: 2g / L; pH: 6.8 electrolyte solution as working electrode, stainless steel as auxiliary electrode, saturated calomel electrode Constitute a three-electrode system for the reference electrode, the area of the cathode and anode is controlled at 5:1, and the voltag...

Embodiment 3

[0032] In this embodiment, the medical titanium alloy bone plate is used as the base material.

[0033] Firstly, the medical titanium alloy bone plate is polished by sandblasting, cleaned with distilled water, then ultrasonically cleaned in acetone for 10 minutes, then chemically degreased in degreasing solution for 10 minutes, rinsed with distilled water and dried, and then placed in a certain molar ratio to NH 4 HF 2 : HNO 3 :H 2 o 2 (1:2:2) acidic solution for activation for 1min, and finally put the titanium alloy sample into the solution at a constant temperature of 25°C to form NH 4 h 2 PO 4 : 50g / L; CH 3 COONH 4 : 25g / L; H 2 o 2 : 20mL / L; sodium gluconate: 2g / L; surfactant sodium dodecylbenzenesulfonate: 2g / L; pH: 6.8 electrolyte solution as working electrode, stainless steel as auxiliary electrode, saturated calomel electrode Constitute a three-electrode system for the reference electrode, the area of the cathode and anode is controlled at 5:1, and the vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com