Graphene oxide/PVDF (polyvinylidene fluoride) blended cation exchange membrane and preparation method thereof

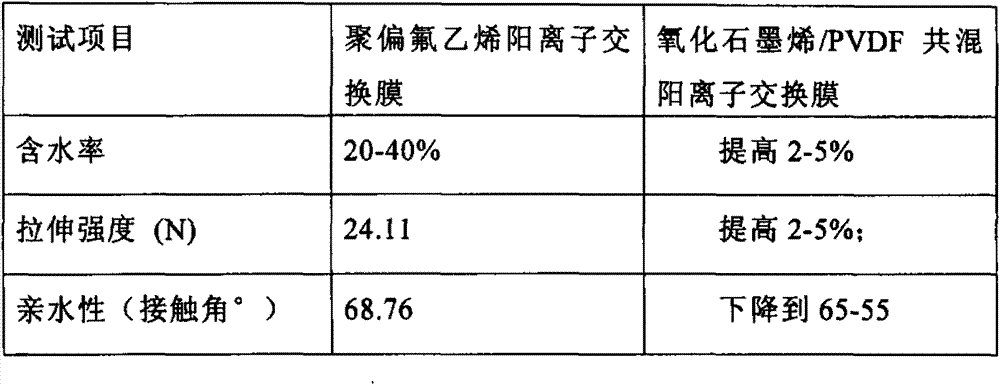

A cation exchange membrane, ion exchange membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of poor dimensional stability, poor anti-pollution ability, poor chemical stability, etc., to improve surface performance. , The effect of improving hydrophilicity and surface densification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A graphene oxide / PVDF blend cation exchange membrane, the ion exchange membrane is made of raw materials with the following components and weight percentages: polyvinylidene fluoride (PVDF) 5, graphene oxide 0.3, organic solvent 70, diethylene Benzene 13, glycidyl methacrylate 10, benzoyl peroxide 1.7.

[0051] Among them, the molecular weight of polyvinylidene fluoride is 400,000 to 600,000 Daltons. Graphene oxide is in the form of flakes. The organic solvent is N-N dimethylacetamide.

[0052] A preparation method of graphene oxide / PVDF blended cation exchange membrane includes the following steps:

[0053] (1) Prepare materials according to the following components and weight percentages: polyvinylidene fluoride (PVDF) 5, graphene oxide 0.3, organic solvent 70, divinylbenzene 13, glycidyl methacrylate 10, benzoyl peroxide 1.7 ;

[0054] (2) Dissolve graphene oxide in 50wt% organic solvent, and ultrasonically disperse for 2h;

[0055] (3) Dissolve polyvinylidene fluoride in ...

Embodiment 2

[0063] A graphene oxide / PVDF blended cation exchange membrane, the ion exchange membrane is made of raw materials with the following components and weight percentages: polyvinylidene fluoride (PVDF) 10, graphene oxide 0.1, organic solvent 55, diethylene Benzene 14.4, glycidyl methacrylate 20, benzoyl peroxide 0.5.

[0064] Among them, the molecular weight of polyvinylidene fluoride is 400,000 to 600,000 Daltons. Graphene oxide is in the form of flakes. The organic solvent is N-N dimethylformamide.

[0065] A preparation method of graphene oxide / PVDF blend cation exchange membrane includes the following steps:

[0066] (1) Prepare materials according to the following components and weight percentages: polyvinylidene fluoride (PVDF) 10, graphene oxide 0.1, organic solvent 55, divinylbenzene 14.4, glycidyl methacrylate 20, benzoyl peroxide 0.5 ;

[0067] (2) Dissolve graphene oxide in 50wt% organic solvent, and ultrasonically disperse for 3h;

[0068] (3) Dissolve polyvinylidene fluori...

Embodiment 3

[0076] A graphene oxide / PVDF blended cation exchange membrane, the ion exchange membrane is made of raw materials with the following components and weight percentages: polyvinylidene fluoride (PVDF) 10, graphene oxide 1, organic solvent 60, diethylene Benzene 16, glycidyl methacrylate 12, benzoyl peroxide 1.

[0077] Among them, the molecular weight of polyvinylidene fluoride is 400,000 to 600,000 Daltons. Graphene oxide is in the form of flakes. The organic solvent is N-N dimethylacetamide.

[0078] A preparation method of graphene oxide / PVDF blend cation exchange membrane includes the following steps:

[0079] (1) Prepare materials according to the following components and weight percentages: polyvinylidene fluoride (PVDF) 10, graphene oxide 1, organic solvent 60, divinylbenzene 16, glycidyl methacrylate 12, benzoyl peroxide 1 ;

[0080] (2) Dissolve graphene oxide in 50wt% organic solvent, and disperse it ultrasonically for 2.5h;

[0081] (3) Dissolve polyvinylidene fluoride in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| hydrophilicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com