Method for preparing doped perovskite structural material

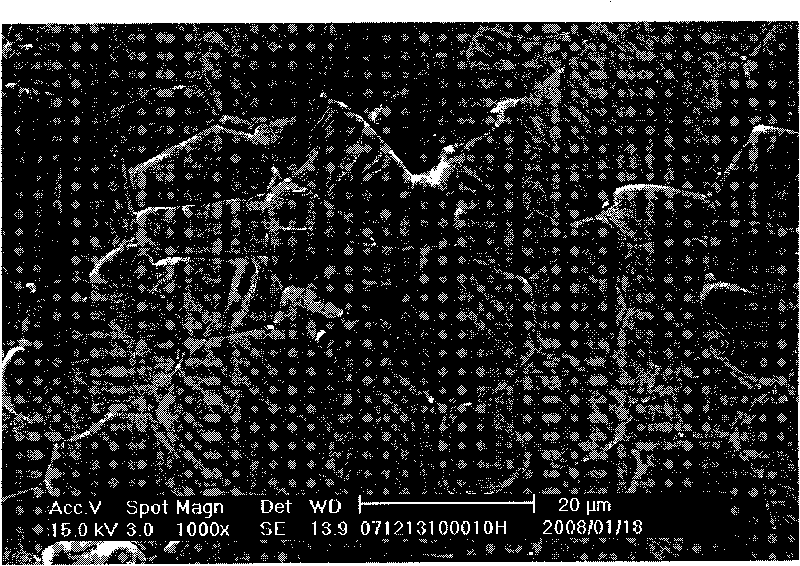

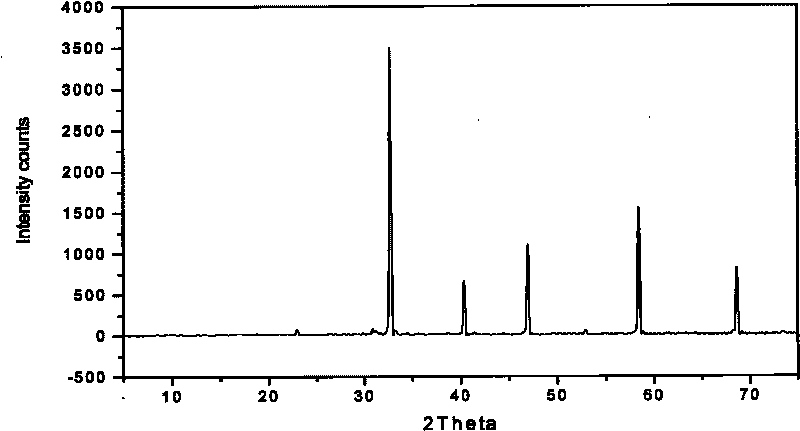

A perovskite structure and composite oxide technology, which is applied in the field of preparation of doped perovskite structure materials, can solve the problem of poor surface density and crystal morphology of powders, poor crystallinity and surface compactness, and non-unique crystal forms etc. to achieve the effect of high selectivity, dense surface and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Accurately weigh 5.29g of strontium nitrate, 1.81g of copper nitrate, 6.06g of iron nitrate, measure TiO(NO 3 ) 2 Add 0.83ml of the solution into a three-necked flask, mix and stir evenly, add 9g of urea and 12ml of ethylene glycol, and keep stirring. At this time, the color of the sol is green, add about 5ml of ammonia water, adjust the pH value to 6.54, and put it in a water bath at 25°C And keep stirring, the color changes from green to dark brown, the viscosity keeps increasing, the temperature is raised to 65°C, and the stirring is continued for 3 hours, the gel is put into the muffle furnace for sintering, the sintering program is controlled from room temperature to 200°C, and the heating rate is 0.1°C / min, keep warm for 30min, and the heating rate is 0.5°C / min at 200-400°C. Keep it warm for 30min, then raise the temperature to 850°C at a heating rate of 1°C and min, and keep it warm for 4 hours to obtain a material with a single crystal form and a high crystalli...

Embodiment 2

[0028] Accurately weigh 6g of zirconium nitrate, 4.2g of copper nitrate, 6.06g of manganese nitrate, measure TiO(NO 3 ) 2 Add 0.8ml of the solution into a three-necked flask, mix and stir evenly, add 20g of citric acid and 30ml of glycerol, and keep stirring. At this time, the color of the sol is green. Add about 10ml of ammonia water, adjust the pH value to 7.0, and set the temperature at 25°C Water bath and constant stirring, the color changes from green to yellow, the viscosity continues to increase, the temperature is raised to 90°C, and the stirring is continued for 6 hours, the gel is put into the muffle furnace for sintering, the sintering program is controlled from room temperature to 200°C, and the heating rate 0.5°C / min, heat preservation 30min, 200-400°C heating rate 1°C / min. Keep it warm for 30 minutes, then raise the temperature to 1000° C. at a heating rate of 5° C. / min, and hold it for 6 hours to obtain a perovskite structure material with a single crystal form...

Embodiment 3

[0030] Accurately weigh 5.29g of strontium nitrate, 4.2g of copper nitrate, 6.06g of manganese nitrate, measure TiO(NO 3 ) 2 Add 0.8ml of the solution into a three-necked flask, mix and stir evenly, add 20g of citric acid and 30ml of methanol, and keep stirring. At this time, the color of the sol is light green. Add about 15ml of ammonia water, adjust the pH value to 8.5, and stir at room temperature. The color changed from light green to orange yellow, and the viscosity continued to increase. The temperature was raised to 80°C and continued to stir for 8 hours. The gel was sintered in a muffle furnace. The sintering program was controlled from room temperature to 200°C, and the heating rate was 0.1°C / min, keep warm for 30min, and the heating rate is 0.8℃ / min at 200-400℃. Keep it warm for 30 minutes, then raise the temperature to 1100° C. at a heating rate of 3° C. / min, and hold it for 10 hours to obtain a material with a single crystal form and a high crystallinity perovski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com