Electrolytic solution for differential arc oxidization surface treatment of magnesium aluminum alloy in aluminates system

A micro-arc oxidation and aluminate technology, applied in anodizing and other directions, can solve the problem of no aluminate system research, and achieve a broad market and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: The electrolytic solution is a single sodium aluminate system, and the sodium aluminate is 4 g / L according to the ratio of weight to total volume. Place the sample in the electrolyte, connect the positive pole of the power supply, and connect the stainless steel tank to the negative pole of the power supply. The constant current method is used to control the micro-arc oxidation process, and the current density is constant at 3A / dm 2 . From the experimental phenomenon, the reaction is stable, but due to the low solute concentration and low current density, the film formation rate is very small, and the film thickness is only 3 microns after oxidation for 20 minutes. When the voltage rises to 500V, the arc starts and the spark is blue. During the experiment, there is a very weak popping sound, and the voltage reaches 580V when it is terminated. After oxidation, seal the pores with boiling water and blow dry. It can be seen that a light off-white smooth and d...

Embodiment 2

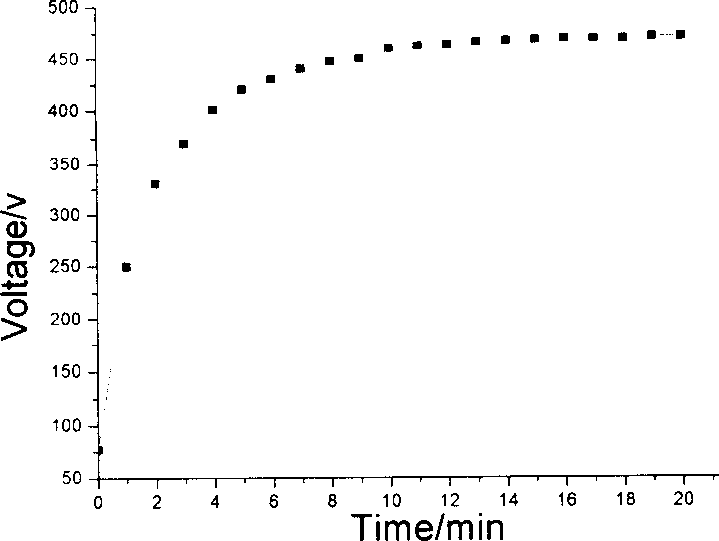

[0029] Example 2: The electrolytic solution is a single aluminate system, and 40 g / L of sodium aluminate is used according to the ratio of weight to total volume. The current density is constant at 5A / dm 2 , After 20 minutes, the voltage remained at 424 volts, and the remaining operations were the same as the previous example. Due to the high electrolyte concentration, the ceramic layer formed on the surface of the sample after micro-arc oxidation treatment is thicker than that of the previous example, but the roughness is increased.

Embodiment 3

[0030] Example 3: The electrolytic solution is an aluminate composite system. According to the ratio of weight to total volume, 4 g / L of sodium aluminate and 10 g / L of sodium hydroxide are used. The current density was constant at 3A / dm2, and the oxidation was performed for 20 minutes, and the rest of the operations were the same as those in the previous example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com