All-in-one machine for crushing, stirring and screening

An all-in-one machine and crushing chamber technology, applied in cocoa, grain processing, food science, etc., can solve the problems of low degree of automation, unsatisfactory processing quality, low processing efficiency, etc., achieve good effect, maintain pharmacological properties, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

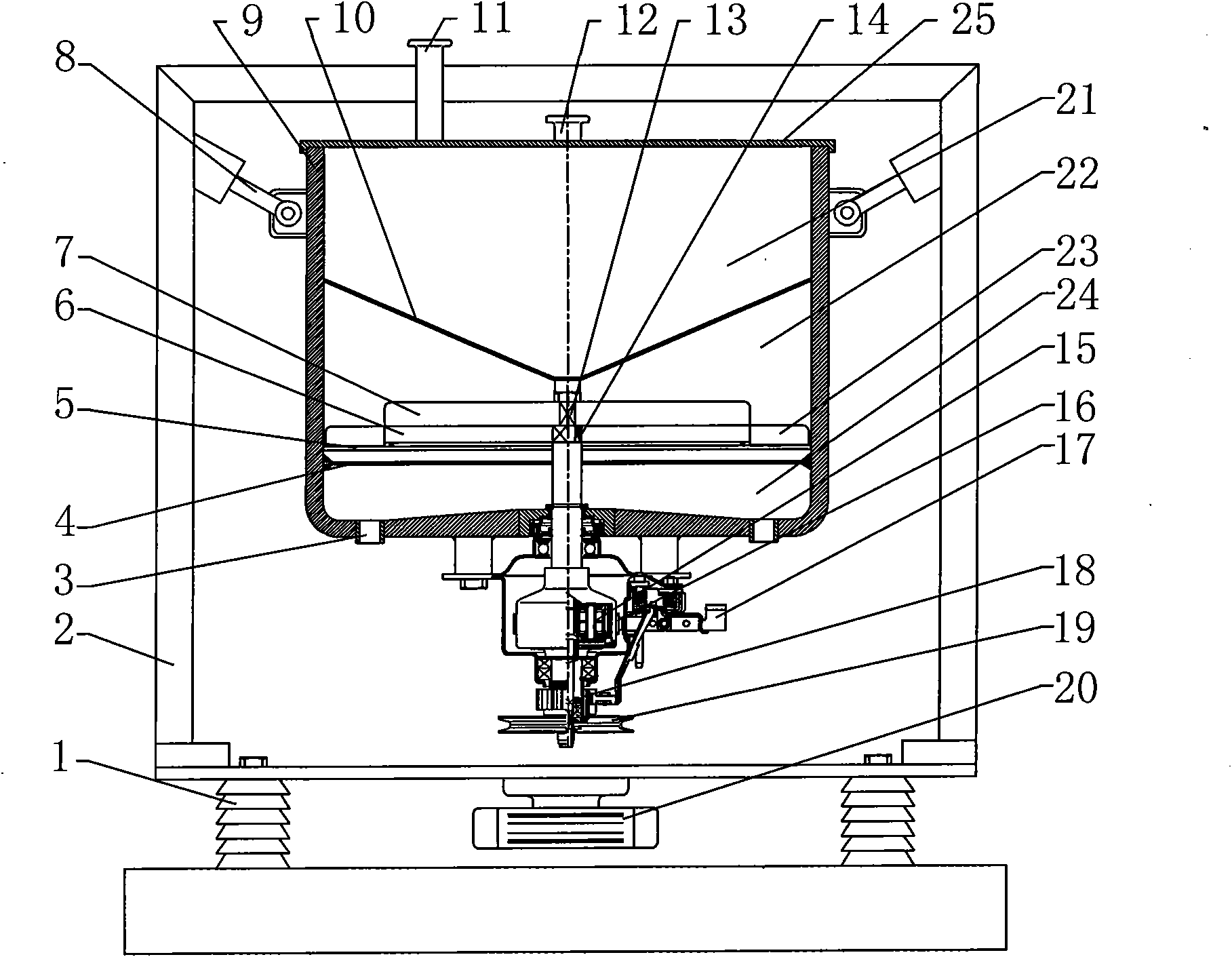

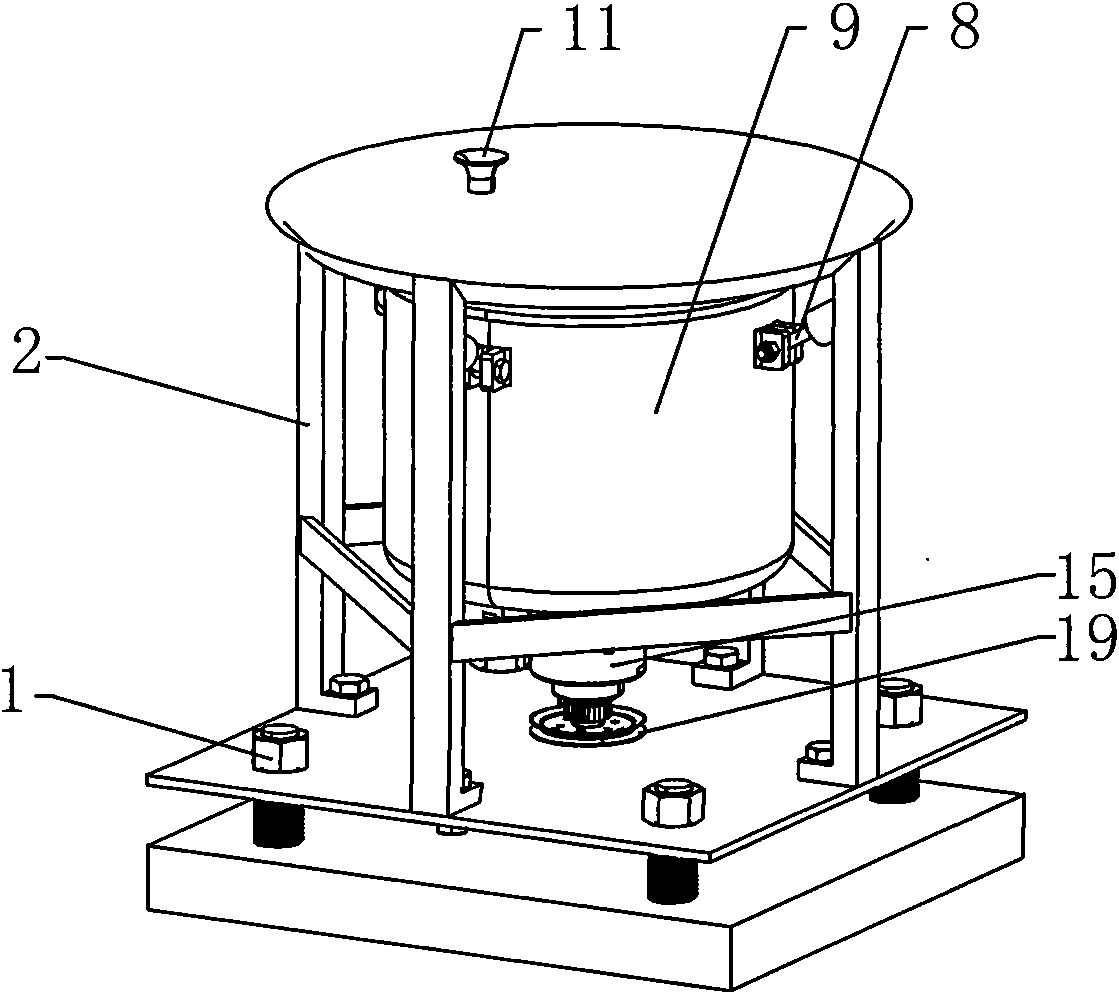

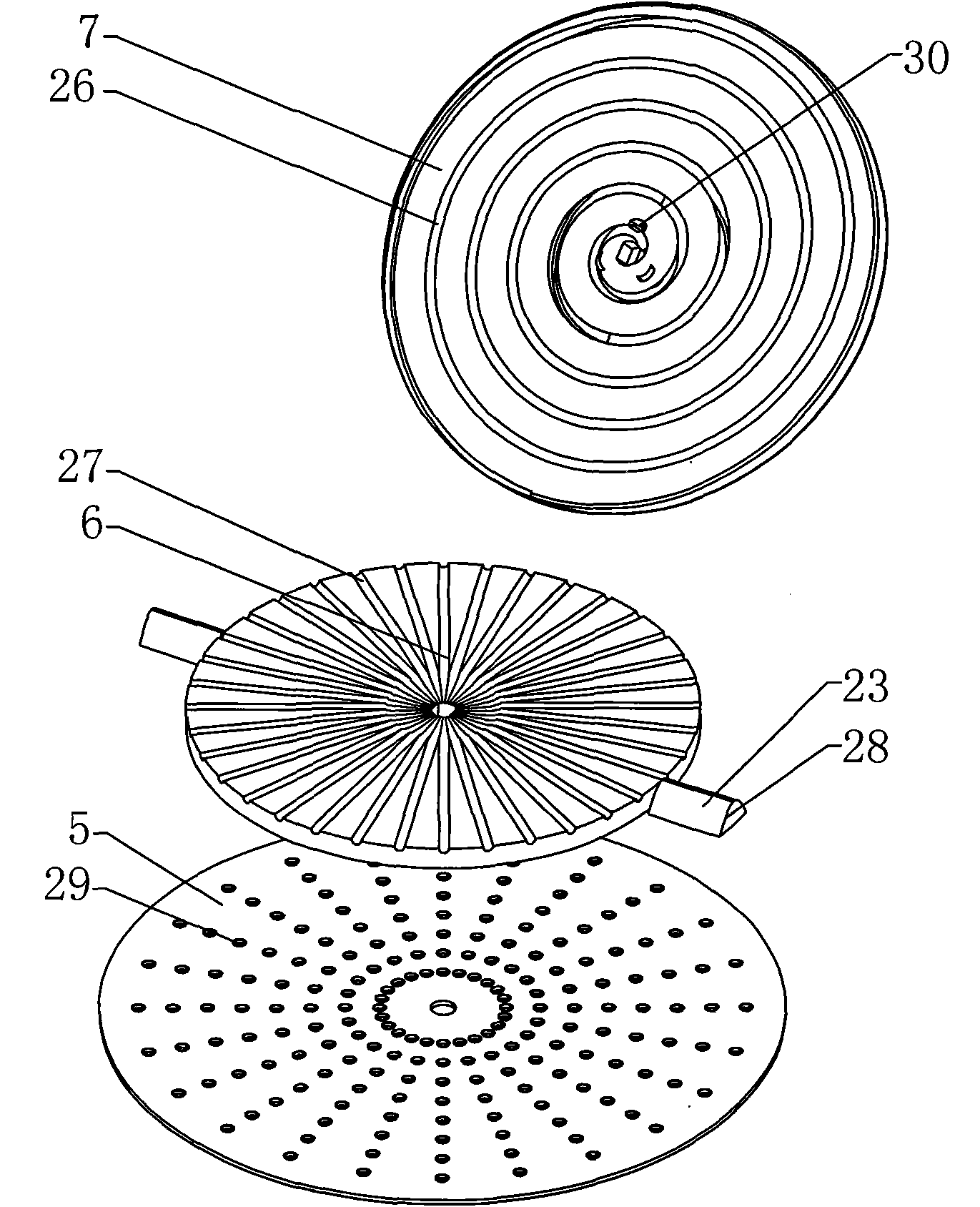

[0020] Such as figure 1 , figure 2 As shown, the cylinder 9 is suspended on the external vibration platform assembly 2 through the universal joint suspension assembly 8 connected to the outer surface. The vibration motor 20 is arranged in the center of the bottom of the vibration platform assembly 2, and the bottom is fixed on the horizontal foundation surface through the elastic support 1. . The interior of the cylinder 9 is divided into an upper feeding chamber 21, a middle pulverizing chamber 22 and a lower storage chamber 24 by the cone bucket 10 and the tray 5. The bottom of the cone bucket 10 has a hole connected to the feeding port of the crushing tray 7, and the crushed material The disc 7 has the same diameter as the stirring disc 6, stacked up and down, and is located on the upper part of the tray 5. The outer edge of the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com