Novel asymmetrical hole-channel structure of filter body of particulate trap

A particle filter and pore structure technology, which is applied to machines/engines, mufflers, engine components, etc., can solve the problems of increasing the post-processing cost of the regeneration frequency, shortening the service life of the particle filter, and affecting the performance of the diesel engine. The effect of prolonging the service life and reducing the regeneration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below according to the accompanying drawings.

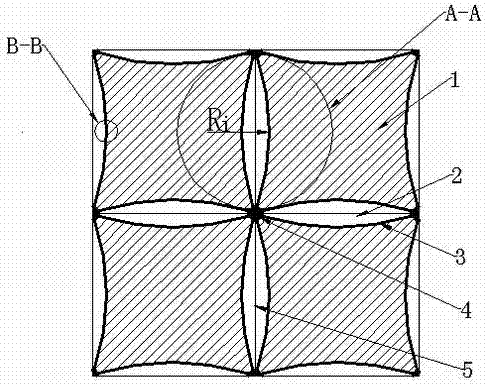

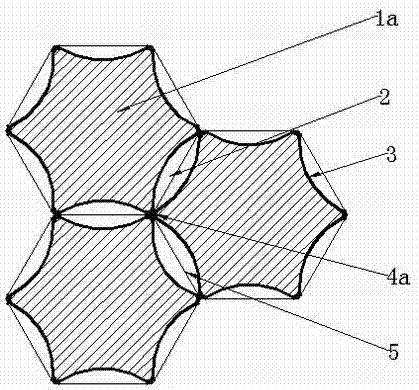

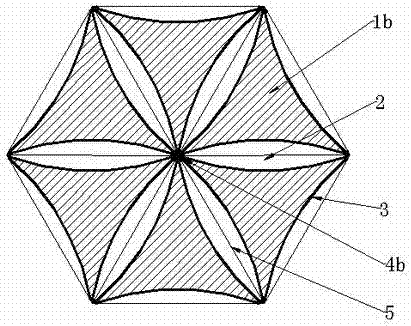

[0026] figure 1 A schematic cross-sectional view of the novel filter body structure is shown. As shown in the figure, the new filter channel structure is designed to be narrow and long, and its shape is a leaf-shaped channel 2 composed of two arc-shaped or wave-shaped channel walls 3 in opposite directions. The size Ri, i=1, 2, 3...6 is adjustable, and the size is the same or different; the centerline 5 of the cross-section of the leaf-shaped channel is surrounded by a square, and the intersection of the wall 3 of the arc-shaped or wave-shaped channel adopts the first type of skeleton structure 4 The wall surface of the supporting channel is supported; the quadrilateral curved surface channel 1 surrounded by four arc-shaped or wave-shaped channel wall surfaces 3 is used as an air intake channel; a new asymmetric channel structure with a large surface-to-volume ratio is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com