Hippophae rhamnoides black tea and preparation method thereof

A technology of sea buckthorn black tea and sea buckthorn leaves is applied in the direction of tea substitutes, etc., and can solve the problems of unguaranteed fermentation quality, long fermentation period, and unsatisfactory fermentation quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

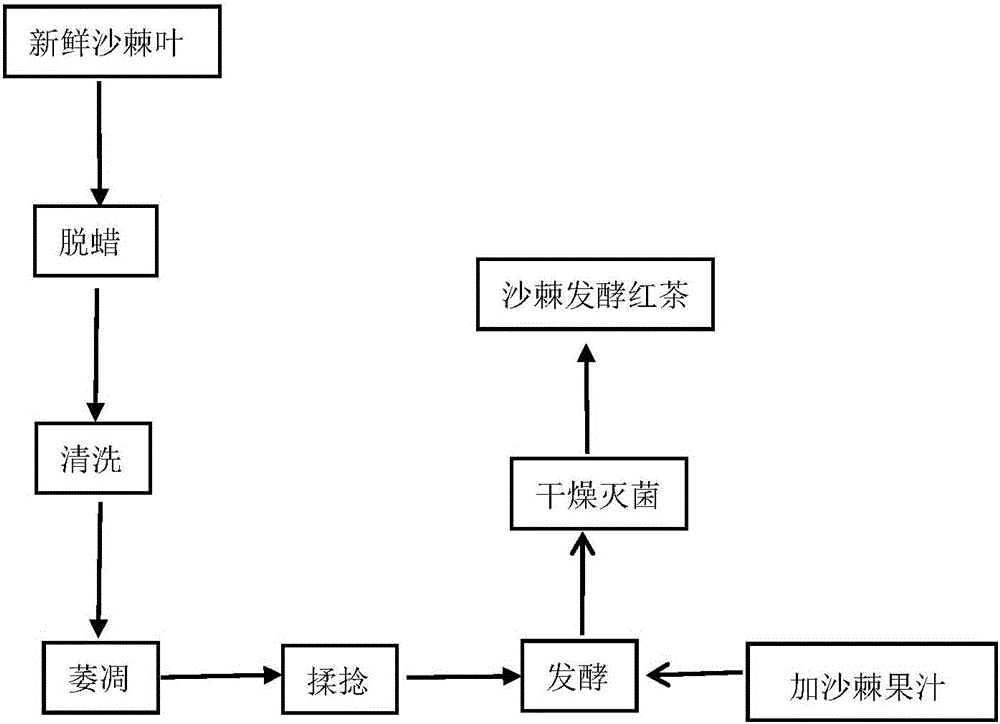

Method used

Image

Examples

Embodiment 1

[0031] (1) Harvest seabuckthorn leaves: collect fresh seabuckthorn leaves.

[0032] (2) Dewaxing treatment of seabuckthorn leaves: place seabuckthorn leaves in a container equipped with a stirring device, and add NaHCO with a concentration of 10% according to the ratio of material to liquid of 1:5 3 solution, maintain the temperature at 15°C, and stir for 5 minutes. Soak the dewaxed seabuckthorn leaves in clean water and stir for 3 minutes to wash off the dewaxing reagent attached to the surface of the tea leaves

[0033] (3) Withering: spread the dewaxed seabuckthorn leaves in a well-ventilated withering room protected from light, and place for 3 hours.

[0034](4) Kneading: Put the withered seabuckthorn leaves into a kneading machine and knead them with air pressure for 5 minutes, light pressure for 10 minutes, heavy pressure for 40 minutes, air pressure for 5 minutes, and a total of 60 minutes of kneading process.

[0035] (5) Fermentation: put the seabuckthorn leaves twi...

Embodiment 2

[0038] (1) Harvest seabuckthorn leaves: collect fresh seabuckthorn leaves.

[0039] (2) Dewaxing treatment of seabuckthorn leaves: place seabuckthorn leaves in a container equipped with a stirring device, and add NaHCO with a concentration of 5% according to the ratio of material to liquid at a ratio of 1:45 3 The solution was maintained at 40°C and stirred for 8 minutes. The dewaxed seabuckthorn leaves were immersed in clean water and stirred for 3 minutes, and the dewaxing reagent attached to the surface of the tea leaves was washed away.

[0040] (3) Withering: spread the dewaxed seabuckthorn leaves in a well-ventilated withering room protected from light, and place for 3.5 hours.

[0041] (4) Kneading: Put the withered seabuckthorn leaves into a kneading machine for kneading. When kneading, take air pressure for 6 minutes, light pressure for 15 minutes, heavy pressure for 45 minutes, air pressure for 6 minutes, and a total of 72 minutes of kneading process.

[0042] (5) ...

Embodiment 3

[0045] (1) Harvest seabuckthorn leaves: collect fresh seabuckthorn leaves.

[0046] (2) Dewaxing treatment of seabuckthorn leaves: place seabuckthorn leaves in a container equipped with a stirring device, and add NaHCO with a concentration of 0.1% according to a ratio of material to liquid of 80 3 The solution was maintained at 60°C and stirred for 10 minutes.

[0047] (3) Withering: spread the dewaxed seabuckthorn leaves in a well-ventilated withering room protected from light, and place for 4 hours.

[0048] (4) Kneading: Put the withered seabuckthorn leaves into a kneading machine for kneading. When kneading, take air pressure for 10 minutes, light pressure for 20 minutes, heavy pressure for 50 minutes, air pressure for 10 minutes, and a total of 90 minutes of kneading process.

[0049] (5) Fermentation: put the seabuckthorn leaves twisted into a spiral shape into a fermentation box, add seabuckthorn juice according to 0.8 times the mass of the seabuckthorn leaves, maintai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com