Container type edible fungi base material fermenting device and method

A kind of fermentation equipment and container-type technology, which is applied in the field of container-type edible fungus base material fermentation equipment, can solve the problems of reducing the quality of edible fungus base material, increasing labor costs, and imperfect control equipment, so as to save construction costs and labor costs, Avoid long-distance transportation and save labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

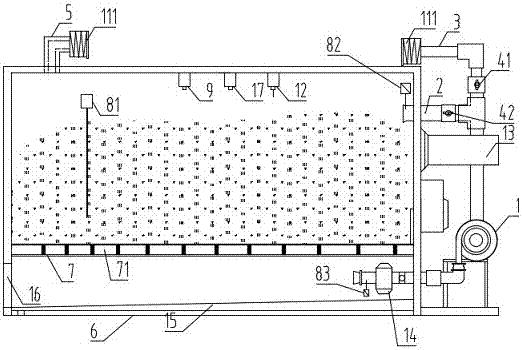

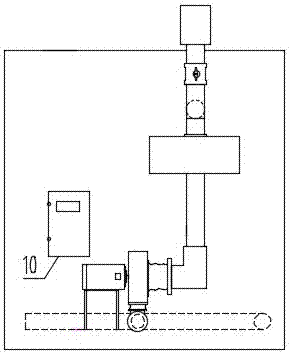

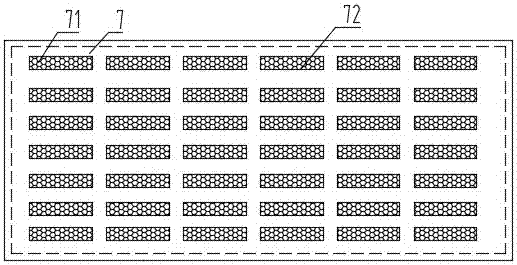

[0042]A container-type edible fungus base material fermentation equipment, comprising a container body 6, a fan 1 arranged outside the container body 6, a return air duct 2 connected to the air inlet of the fan 1 and a fresh air intake duct 3 respectively, and a return air duct 2 arranged on the air return duct 2 The damper controller 42 on the nozzle and the damper controller 41 located on the nozzle of the fresh air inlet pipe 3, and the natural air outlet 5 arranged at the top of the container body 6; the inside of the container body 6 is provided with a steel plate Mechanism 7, several air vents 71 are uniformly distributed on the steel plate mechanism 7; the steel plate mechanism 7 forms an air passage with the bottom of the container body 6, and the air passage communicates with the air outlet of the fan 1; the insi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com