Filtering apparatus for lubricating oil production

A technology of filtering device and lubricating oil, applied in the direction of filtration and separation, moving filter element filter, separation method, etc., can solve the problems of affecting the performance of lubricating oil, affecting the efficiency of filtration, slow passing through the filter screen, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

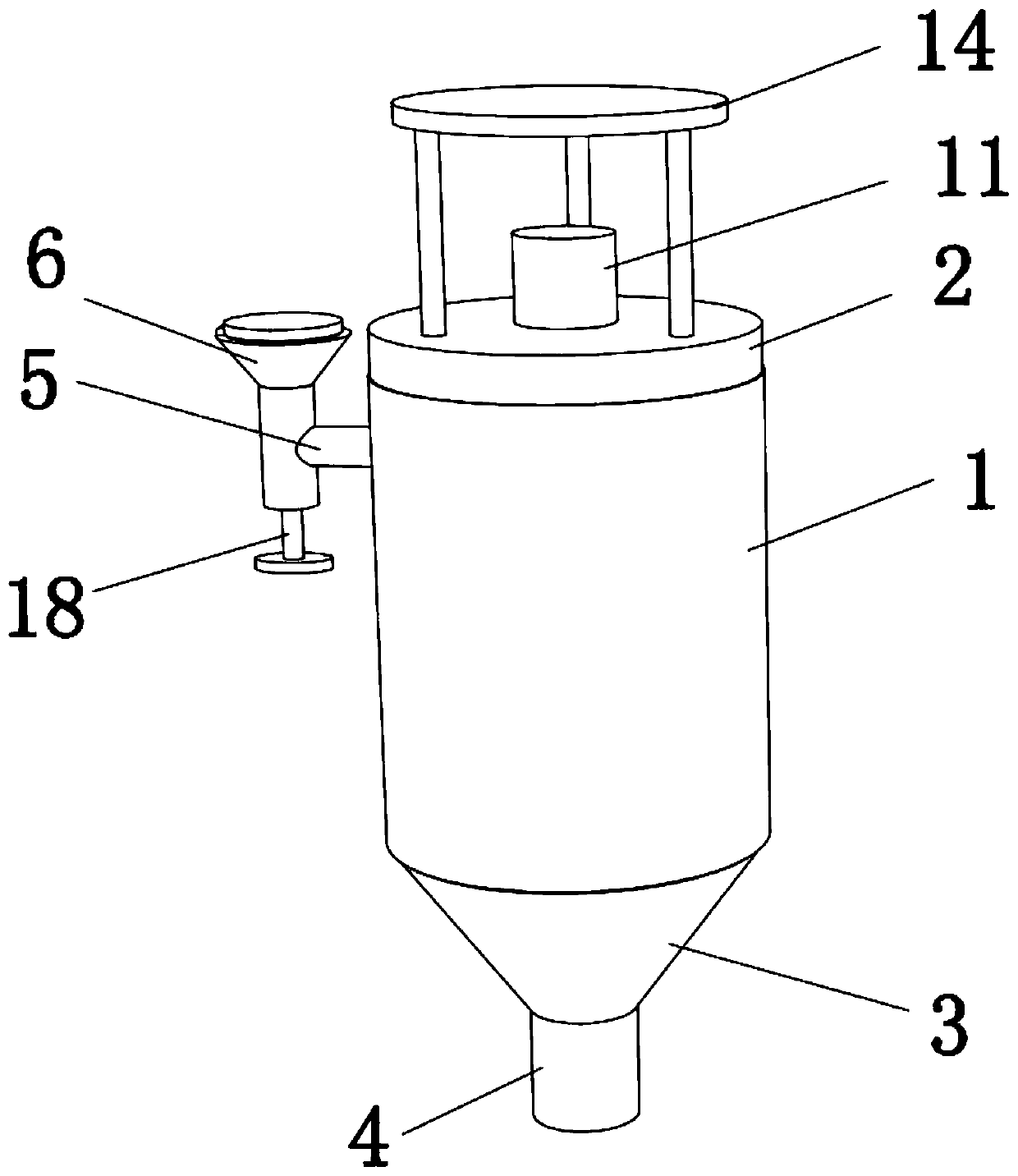

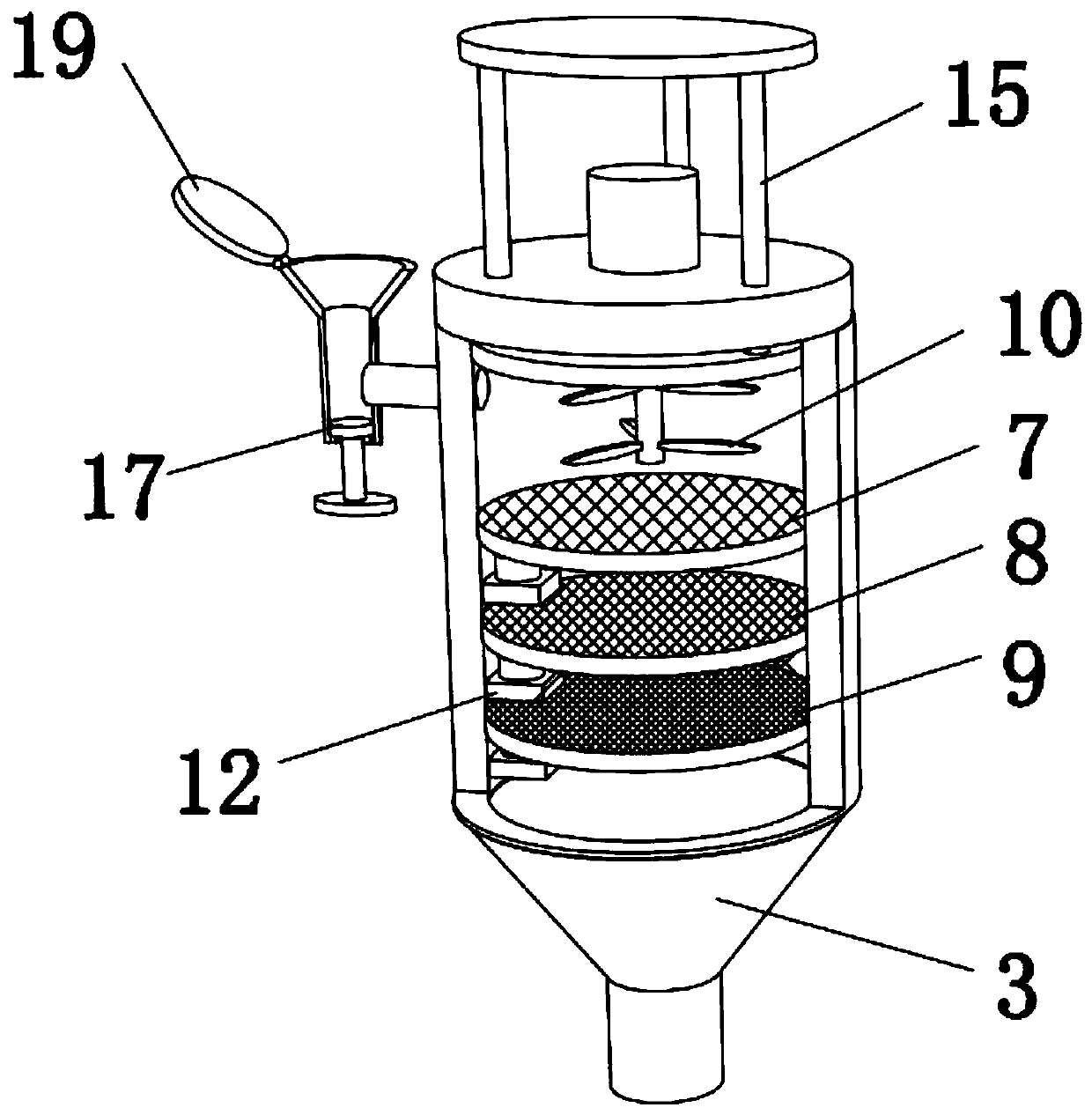

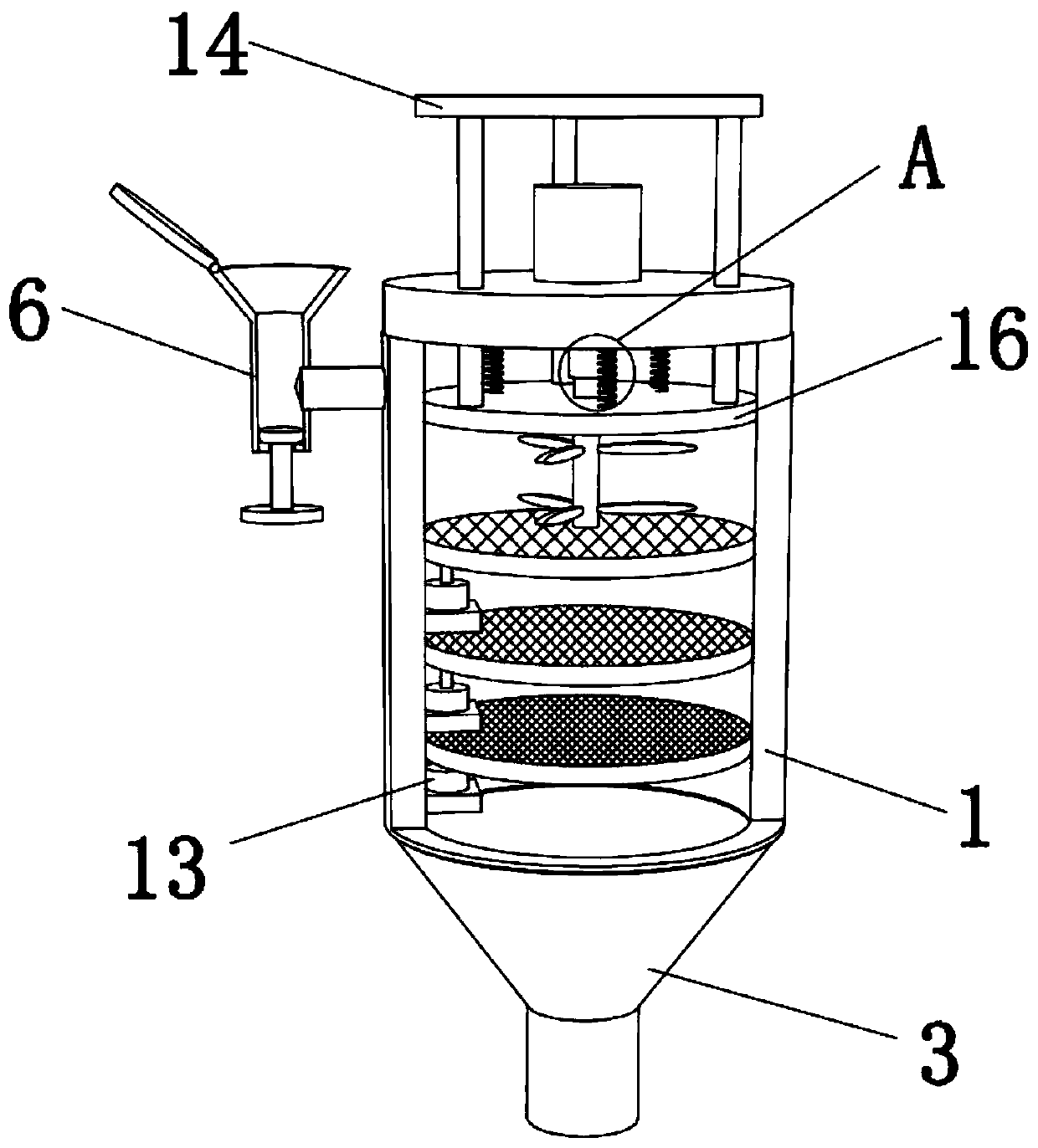

[0031] Reference Figure 1-4 , A filter device for lubricating oil production, comprising a filter box 1, and the inside of the filter box 1 is sequentially connected with a first filter screen 7, a second filter screen 8 and a third filter screen 9 from top to bottom, and the filter box body 1 The side end is connected with an oil guide tube 5, and the end of the oil guide tube 5 away from the filter box 1 is connected with a dredge feeding device. The upper end of the filter box 1 is connected with a sealing cover 2, and the upper end of the sealing cover 2 is connected with a stirring drive device 11 and a sealing cover 2 A through hole is excavated in the center. The power output end of the stirring drive device 11 penetrates through the hole and is connected with a rotating shaft 20. The stirring drive device 11 can select the best type of motor according to actual needs. The side end of the rotating shaft 20 is connected with multiple stirring blades. 10. A dredging mecha...

Embodiment 2

[0042] Reference figure 2 with image 3 , A filter device for lubricating oil production. Compared with the first embodiment, the inner wall of the filter box 1 is connected with a plurality of mounting seats 12, and the plurality of mounting seats 12 are distributed in the first filter 7 and the second filter On the lower side of the net 8 and the third filter net 9, the upper end of the mounting base 12 is connected with a vibration drive device 13, and the vibration drive device 13 can select the best type of vibration motor according to actual needs.

[0043] Working principle: While filtering the lubricating oil, open the vibration driving device 13 to make the filter screen vibrate, so that the mesh of the filter screen is not easily blocked by the filter residue, which is beneficial to the smooth filtering and leakage of the lubricating oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com