Production device capable of raising utilization rate of feed and production method thereof

A production device and production method technology, applied in the direction of biochemical cleaning device, biochemical equipment and method, enzymology/microbiology device, etc., can solve the problems of affecting the effect of fermentation, affecting the quality of fermentation, uneven mixing, etc. Achieve the effects of improving efficiency, ensuring activity, and improving mixing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

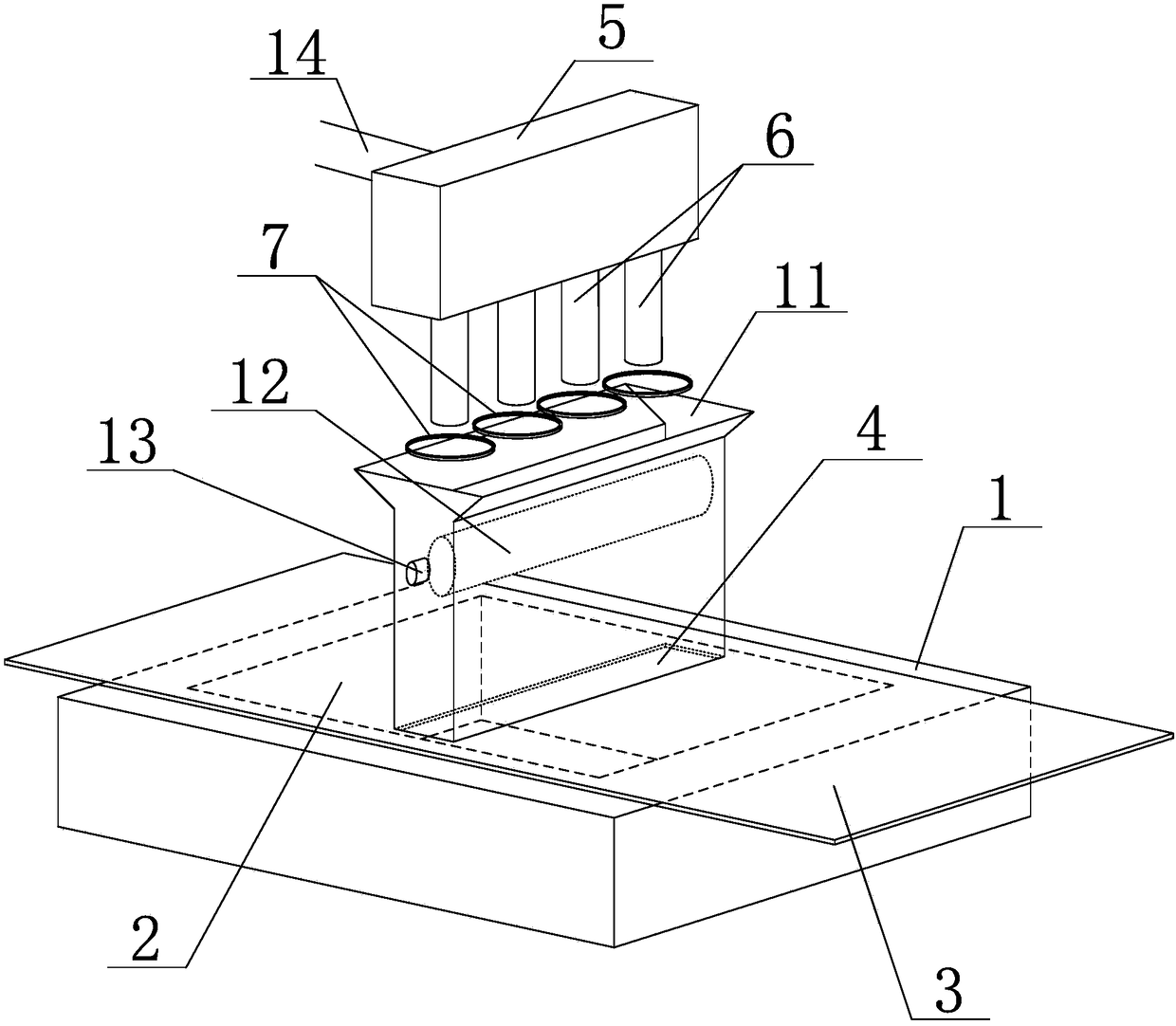

[0033] Such as figure 1 and 2 As shown, the present invention can improve the production device and the production method of feed utilization rate, comprise fermentation platform 1, be provided with fermentation tank 2 on the fermentation platform 1, be covered with closed cover plate 3 on the surface of fermentation platform 1 above the opening of fermentation tank 2, The closed cover plate 3 is provided with a strip-shaped feeding hole 4 parallel to the edge of the fermentation tank, the bottom surfaces of both ends of the closed cover plate 3 are slidingly connected with the surface of the fermentation table 1, and the closed cover plate 3 can be inserted along the strip-shaped inlet. The material hole 4 moves back and forth in the vertical direction; the top of the opening of the fermentation tank 2 is provided with a storage distribution box 5, and the bottom of the storage distribution box 5 is connected with a plurality of discharge pipes 6 along the direction parallel ...

Embodiment 2

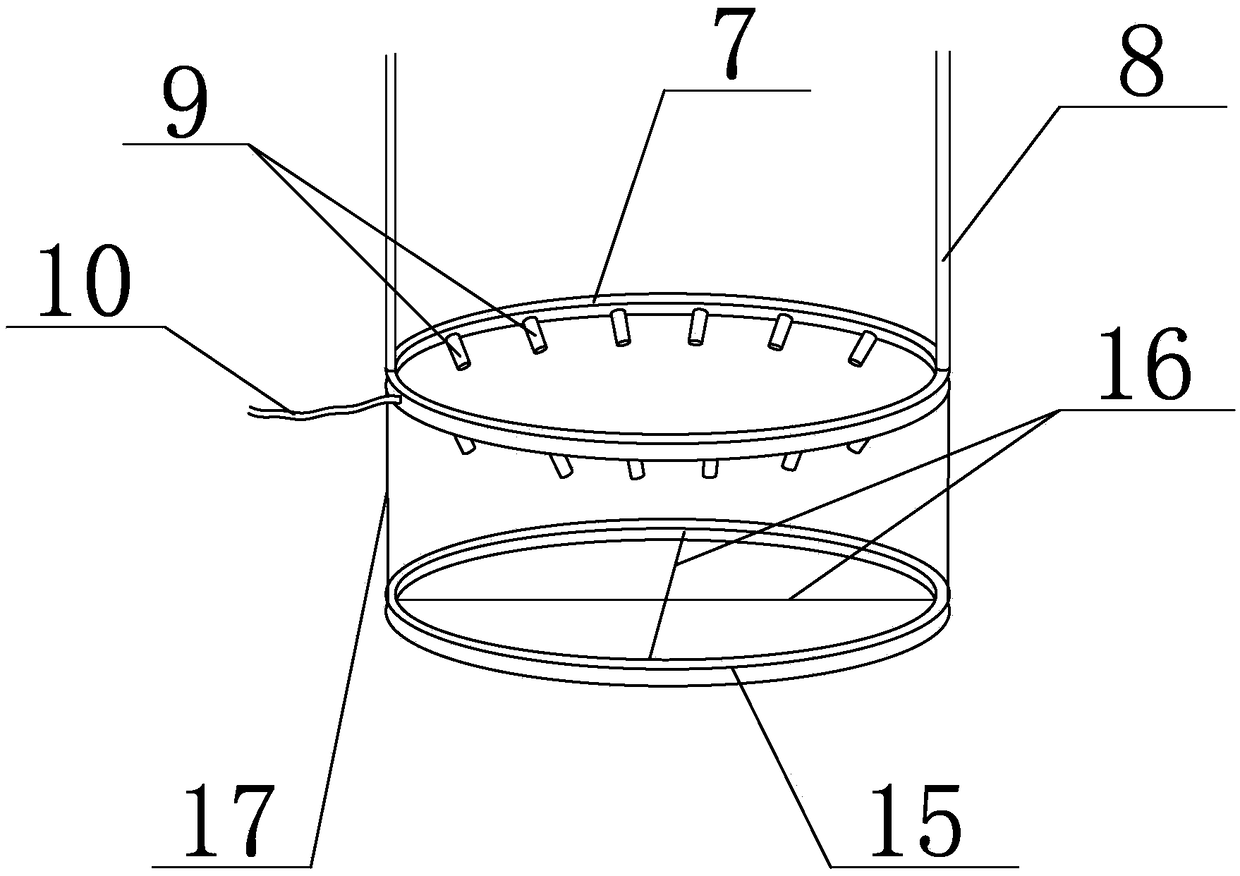

[0040] Such as figure 2 Shown, on the basis of embodiment 1, the production device of the subject number feed utilization rate of the present invention, the coaxial section ring 15 is arranged on the bottom of the spray ring of the fermentation bacteria liquid, and a plurality of intersecting rings are arranged on the inner radial direction of the segmentation ring. The dividing line 16 of the fermentation bacteria liquid spray ring and the dividing ring are connected by a cylindrical splash-proof cloth 17, wherein the intersection between the dividing lines coincides with the intersection of all nozzle extension lines on the fermentation bacteria liquid spray ring , because the nozzles in all directions spray toward the center obliquely downward, then the bacteria solution sprayed by all the nozzles must have a crossing point, which will cause the content of the bacteria solution to increase at this intersection point, so through A plurality of dividing lines arranged crossw...

Embodiment 3

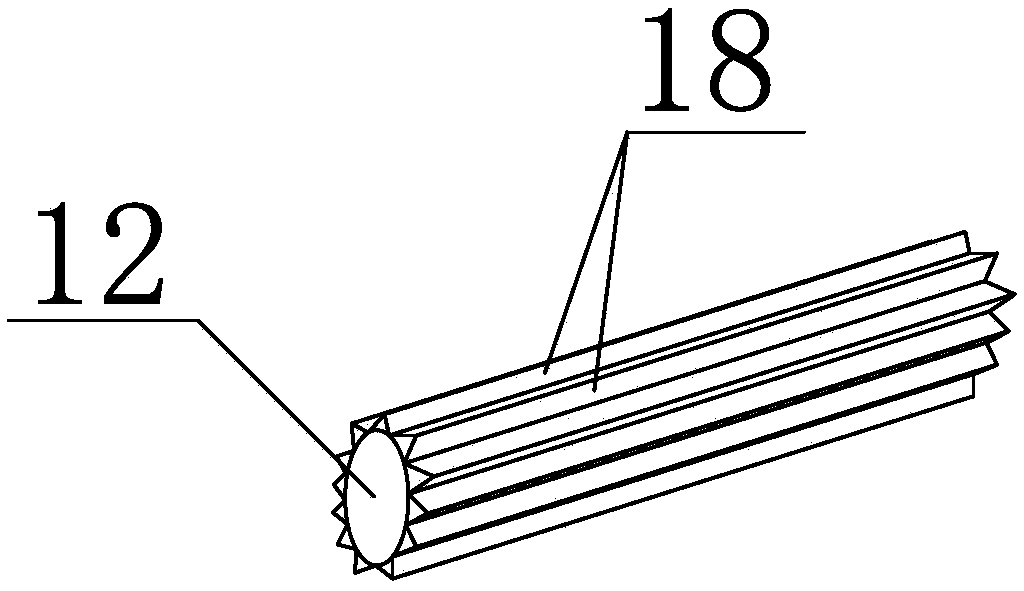

[0043] Such as Figure 4 As shown, on the basis of Example 1, the production device of the subject number feed utilization rate of the present invention, the bottom of the fermentation tank is provided with a stirring device, and the stirring device includes a rotating rod 19 that is vertically arranged at the bottom of the fermentation tank, and the side of the rotating rod The wall is provided with a plurality of quarter-arc stirring plates 20 arranged vertically along the circumferential direction. The stirring plates are grid-shaped. Rotate, and then drive the stirring plate to rotate, so as to further stir the mixed raw materials and bacterial liquid, so that after the fermentation tank is sealed and the raw materials are fermented, the stirring can be continued continuously.

[0044] Furthermore, a heating device is installed in the storage and distribution box to heat the raw materials stored therein to increase the "fluidity" and facilitate the combination of the bacte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com