Liquid lubricating oil filtering device

A technology of filtering device and lubricating oil, which is applied in the directions of filtration and separation, lubricating composition, fixed filter element filter, etc. Fast, long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

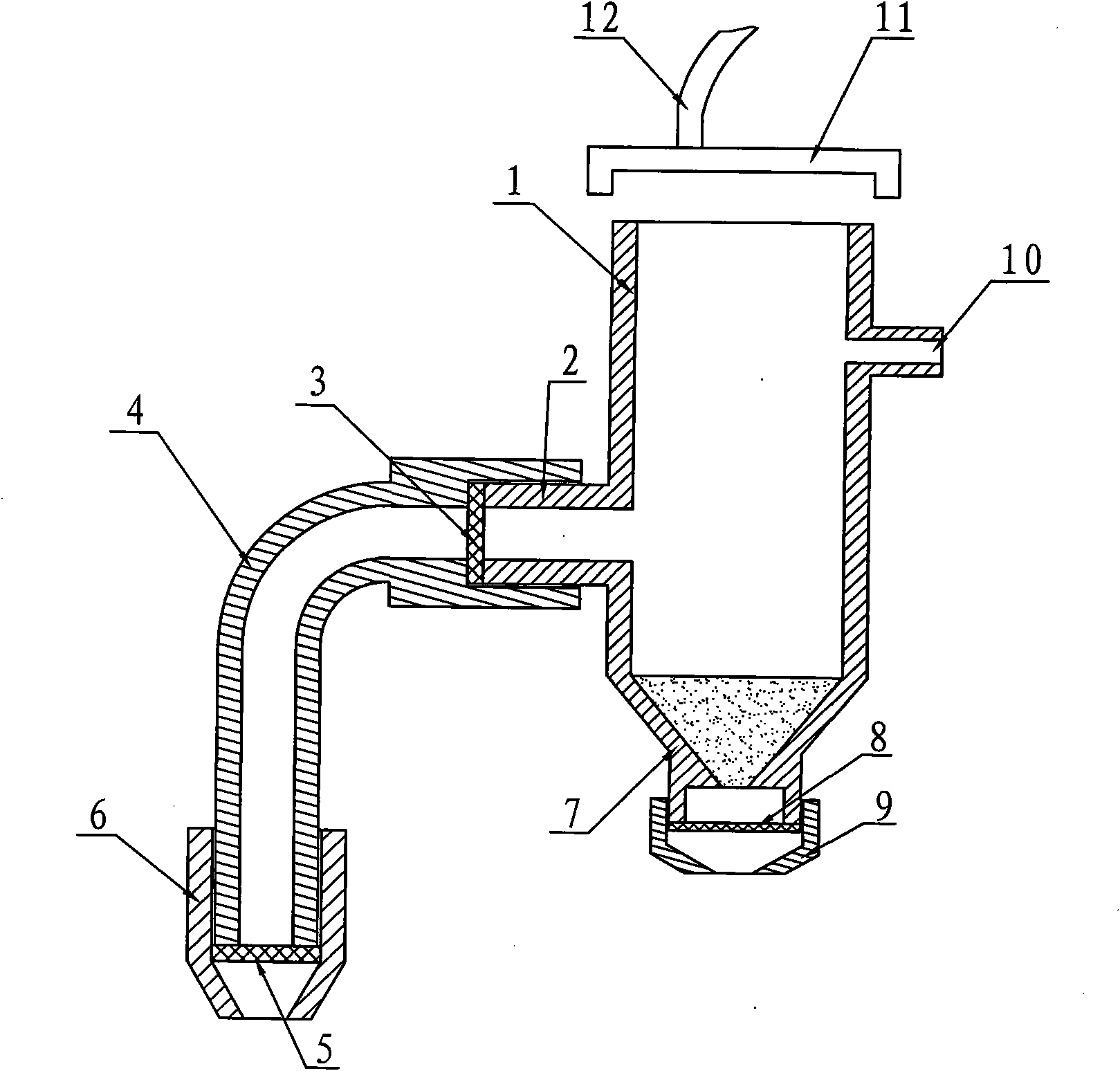

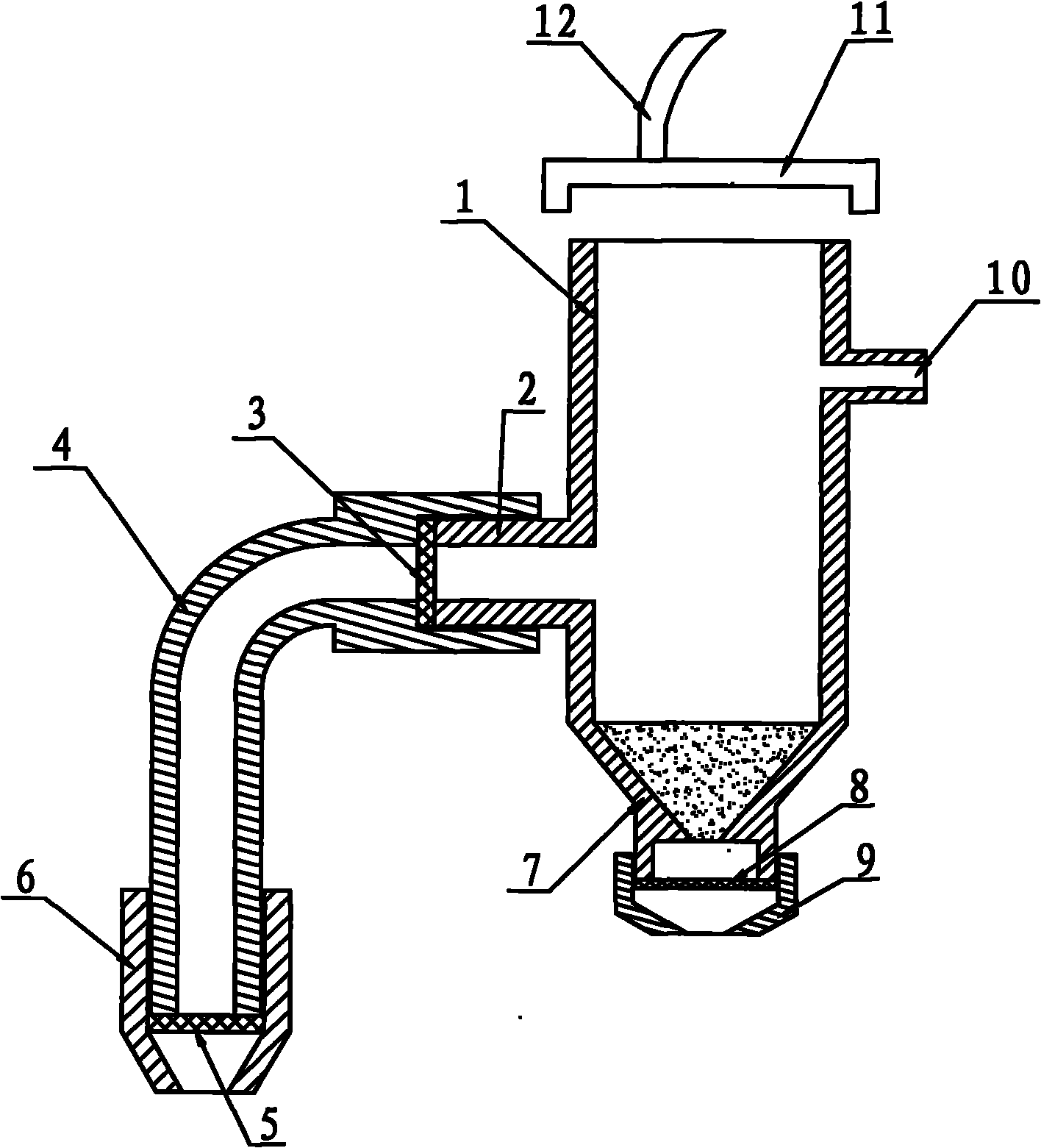

[0011] Described a kind of liquid lubricating oil filtering device, such as figure 1 As shown, it includes filter barrel body 1, side oil outlet joint 2, first filter screen 3, oil outlet elbow 4, second filter screen 5, oil outlet nozzle 6, impurity deposition cone 7, waste oil filter screen 8, waste oil The oil nozzle 9, the pressure port 10, the barrel cover 11 and the oil inlet pipe 12, and the side oil outlet joint 2 are arranged on the side of the lower section of the filter barrel 1, and are located above the impurity deposition cone 7, and the impurity deposition cone 7 is arranged on the filter barrel 1, the oil outlet elbow 4 is installed on the side oil outlet joint 2, the first filter screen 3 is set between the oil outlet elbow 4 and the side oil outlet joint 2, and the second filter screen 5 is set in the oil outlet nozzle 6 , the oil outlet nozzle 6 is installed at the oil outlet end of the oil outlet elbow 4, the waste oil nozzle 9 is installed at the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com