Sporolactobacillus inulinus and method for preparing D-lactic acid by fermenting strains of sporolactobacillus inulinus

A technology of Lactobacillus sporogenes and inulin, which is applied in the field of preparing D-lactic acid, can solve problems such as the failure to implement industrialization, the long distance of industrialization, and the lack of in-depth involvement in D-lactic acid extraction and purification technology, so as to achieve low prices and ensure product quality. Effect of quality and extraction yield, high optical purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Strain screening:

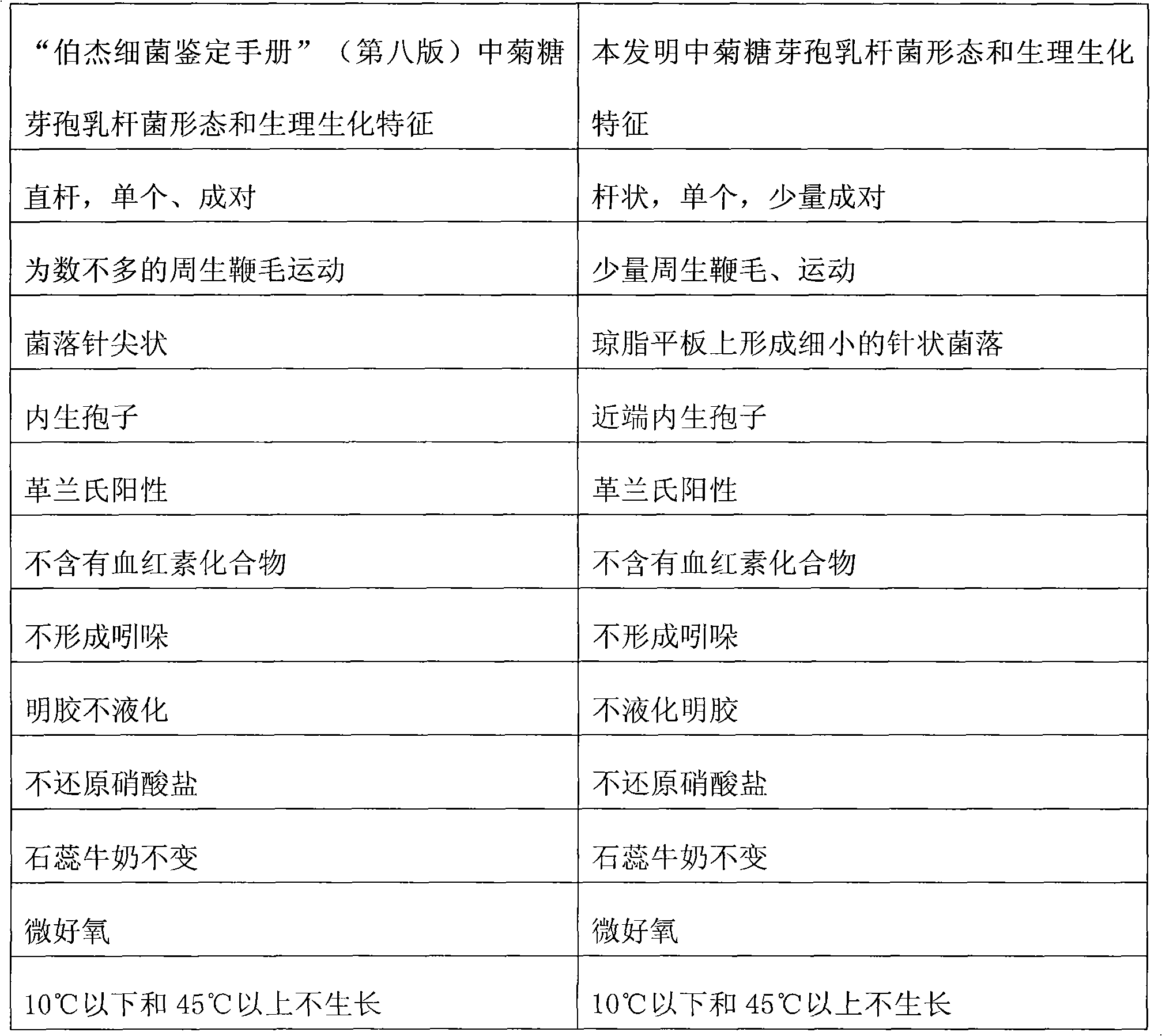

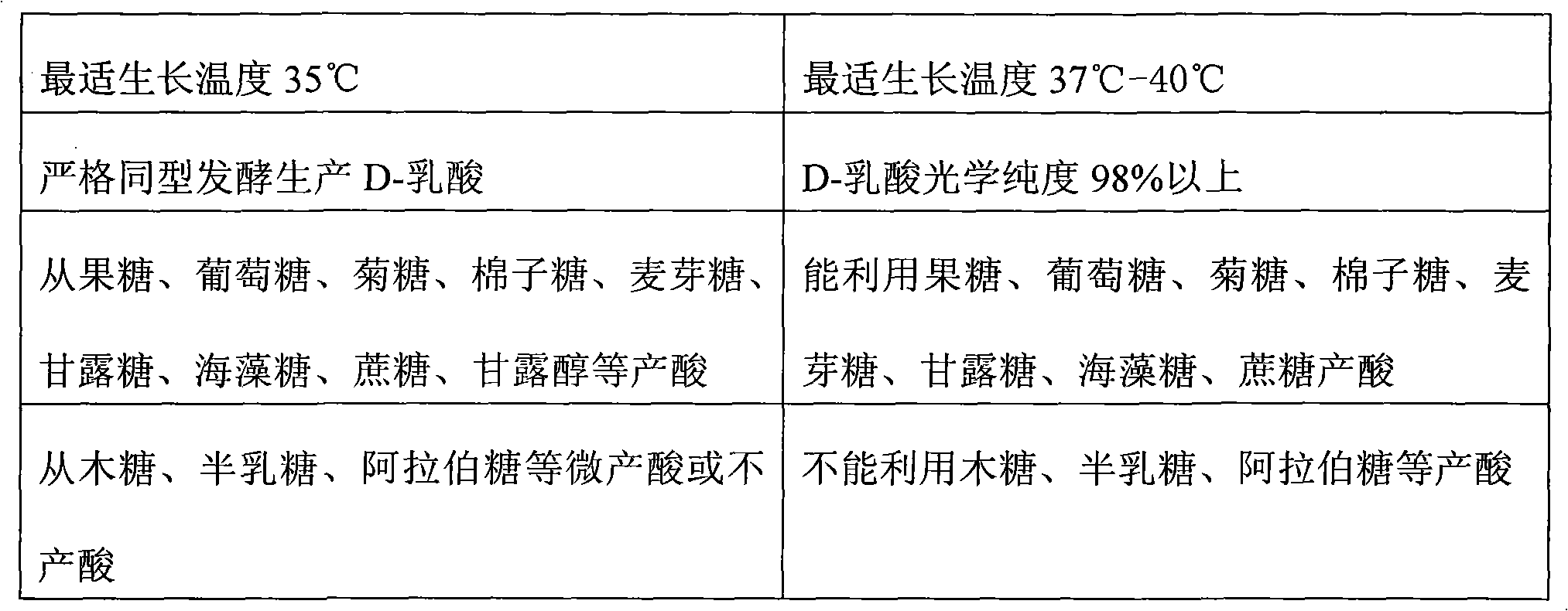

[0057] Collect crude inulin powder from an inulin factory, weigh 5g of inulin powder and dissolve it in 100mL of normal saline, mix well, take 1mL to 9mL of sterile water, shake well to make 10 -1 Diluent. Repeat the above steps to make 10 -2 、10 -3 、10 -4 、10 -5 Diluent, take 10 -3 、10 -4 、10 -5 Spread 0.1mL of the diluted solution on the MRS solid medium and culture at 38°C; after the colony grows, pick a single colony that can dissolve the calcium carbonate in the surrounding medium to form a clear circle, and inoculate it in 25mL of the fermentation medium. After static culture at 38° C. for 72 hrs, the content of D-lactic acid in the fermentation broth was detected according to the detection method described in the above specific embodiments. After multiple screenings, a strain with the highest D-lactic acid production was selected. According to Dong Xiuzhu's "Common Bacteria System Identification Manual" (Science Press 2001) preliminar...

Embodiment 2

[0059] Screening and mutagenesis methods of D-lactic acid bacteria strains:

[0060] After the above-mentioned strain with the highest D-lactic acid production was treated with the chemical mutagen nitrosoguanidine, it was cultured at 37°C in the MRS medium supplemented with sodium lactate (equivalent to 8.0%-10% lactic acid), and a total of 324 resistant strains were obtained. Mutants with increased ability to accept product lactic acid. Finally, the fermentation medium was optimized and the fermentation products of 20 yield positive mutants were quantitatively determined. Through the subculture fermentation test, a D-lactic acid mutant strain DS2-18 with stable high yield, fast growth and high transformation rate was obtained.

Embodiment 3

[0062] D-lactic acid was produced by using soybean meal hydrolyzate from a wide range of sources as a nitrogen source.

[0063] Shake flask seed culture: put 300mL 20g / L glucose solution in a 500mL triangular glass culture bottle, add 10g / L peptone, 10g / L beef extract, 5g / L yeast extract, 2g diammonium hydrogen citrate / L, sodium acetate 5 g / L, dipotassium hydrogen phosphate 2 g / L, manganese sulfate 0.25 g / L, magnesium sulfate 0.5 g / L, Tween 80, 1 g / L, dissolved evenly, sterilized at 121°C for 15 Minutes, cooled to 40°C, put in the Lactobacillus inulin cultured on the slant of a platinum ear test tube, and added 15 g / L of calcium carbonate, sealed the bottle mouth tightly with two layers of flannel cloth and kraft paper. Cultivation was carried out on a shaking table, the cultivation temperature was 40° C., and the rotation speed of the shaking table was 200 r / min. After 16 hours of cultivation, it was inserted into a fermentation culture bottle.

[0064] Shake flask fermenta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com