Brewing process of purple sweet potato vinegar

A purple sweet potato and process technology, which is applied in the field of purple sweet potato vinegar brewing technology, can solve problems such as singleness, and achieve the effects of bright color, strong acidity, and improved quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

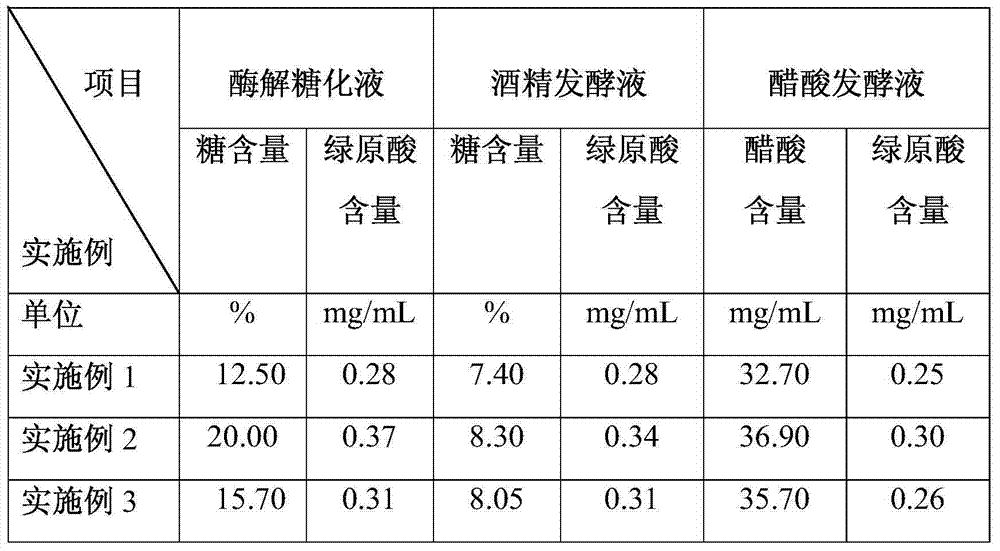

Examples

Embodiment 1

[0026] 1) Raw material processing:

[0027] Select the purple sweet potato that has been stored for more than two months without mildew and deterioration, wash and cut into pieces with skin, then crush the purple sweet potato pieces into purple sweet potato granules with a diameter of less than 1 mm, then mix the purple sweet potato granules with water The solid-to-liquid ratio is 1:1.5, mixed with conventional stirring, and then the purple sweet potato water mixture is heated to 95°C under normal temperature and pressure and kept for 50 minutes to obtain a purple sweet potato slurry, and then the temperature of the purple sweet potato slurry is lowered to below 60℃, standby;

[0028] 2) Enzymatic hydrolysis and saccharification:

[0029] Add a sodium hydroxide solution with a concentration of 0.1 mol / L to the purple sweet potato slurry to adjust the pH to 5, mix amylase and glucoamylase at a mass ratio of 1:1.5 and add to the purple sweet potato slurry wherein, the amylase ...

Embodiment 2

[0037] 1) Raw material processing:

[0038] Select the purple sweet potato that has been stored for more than two months without mildew and deterioration, wash and cut into pieces with skin, then crush the purple sweet potato pieces into purple sweet potato granules with a diameter of less than 1 mm, then mix the purple sweet potato granules with water The solid-to-liquid ratio is 1:2, mixed with conventional stirring, and then the purple sweet potato water mixture is heated to 100°C under normal temperature and pressure and kept for 60 minutes to obtain a purple sweet potato slurry, and then the temperature of the purple sweet potato slurry is lowered to below 60℃, standby;

[0039] 2) Enzymatic hydrolysis and saccharification:

[0040]Add a sodium hydroxide solution with a concentration of 0.1 mol / L to the purple sweet potato slurry to adjust the pH to 5.5, mix amylase and glucoamylase in a mass ratio of 1:1 and add to the purple sweet potato slurry wherein, the amylase an...

Embodiment 3

[0048] 1) Raw material processing:

[0049] Select the purple sweet potato that has been stored for more than two months without mildew and deterioration, wash and cut into pieces with skin, then crush the purple sweet potato pieces into purple sweet potato granules with a diameter of less than 1 mm, then mix the purple sweet potato granules with water The solid-to-liquid ratio is 1:2, mixed with conventional stirring, and then the purple sweet potato water mixture is heated to 100°C under normal temperature and pressure and kept for 60 minutes to obtain a purple sweet potato slurry, and then the temperature of the purple sweet potato slurry is lowered to below 60℃, standby;

[0050] 2) Enzymatic hydrolysis and saccharification:

[0051] Add a sodium hydroxide solution with a concentration of 0.1 mol / L to the purple sweet potato slurry to adjust the pH to 5.7, mix amylase and glucoamylase at a mass ratio of 1:2 and add to the purple sweet potato slurry wherein, the amylase a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com