Combined polypropylene thermal spray fiber membrane folding type filter element

A technology of polypropylene and fiber membrane, which is applied in the field of clarification device, liquid particle removal, and combined polypropylene thermal spray fiber membrane pleated filter element, which can solve the problems of unguaranteed filtration efficiency, short service life of filter element, unstable quality of filtrate, etc. problems, to achieve the effect of ensuring filtration accuracy and efficiency, prolonging the service life and increasing the amount of dirt held

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

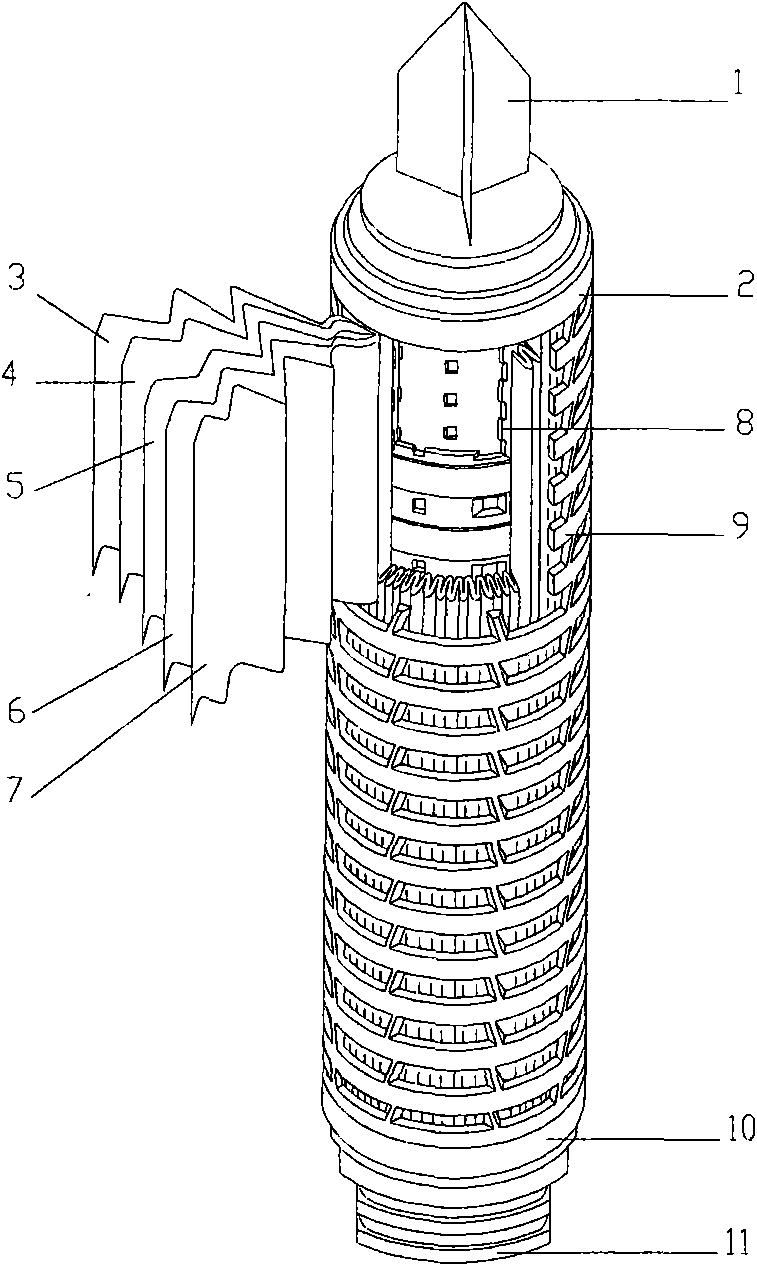

[0013] Such as figure 1 As shown, a combined polypropylene heat-sprayed fiber membrane pleated filter element of the present invention is composed of a filter medium layer, an inner support cylinder 8 and an outer support cylinder 9, and the filter medium layer is folded into fins and then surrounded inside On the outer circumference of the support cylinder 8, the folding line of the filter medium layer is parallel to the axial direction of the inner support cylinder 8, and the outer support cylinder 9 is sleeved on the outside of the cylinder formed by the filter medium layer, wherein the filter The medium layer is composed of polypropylene thermal sprayed fiber film 4, polypropylene thermal sprayed fiber film 5, polypropylene thermal sprayed fiber film 6, protective layer 3 and protective layer 7, and polypropylene thermal sprayed fiber film 4, polypropylene thermal sprayed film The fiber film 5 and the polypropylene thermal sprayed fiber film 6 are adjacent in sequence, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com