Boiler gray water treatment and recycling device

A technology for water treatment and boiler ash, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, sedimentation treatment, etc. It can solve the problems of a large amount of investment, occupying a large area of land, and difficulty in discharging sludge. Achieve the effect of large dirt holding capacity, not easy to break, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

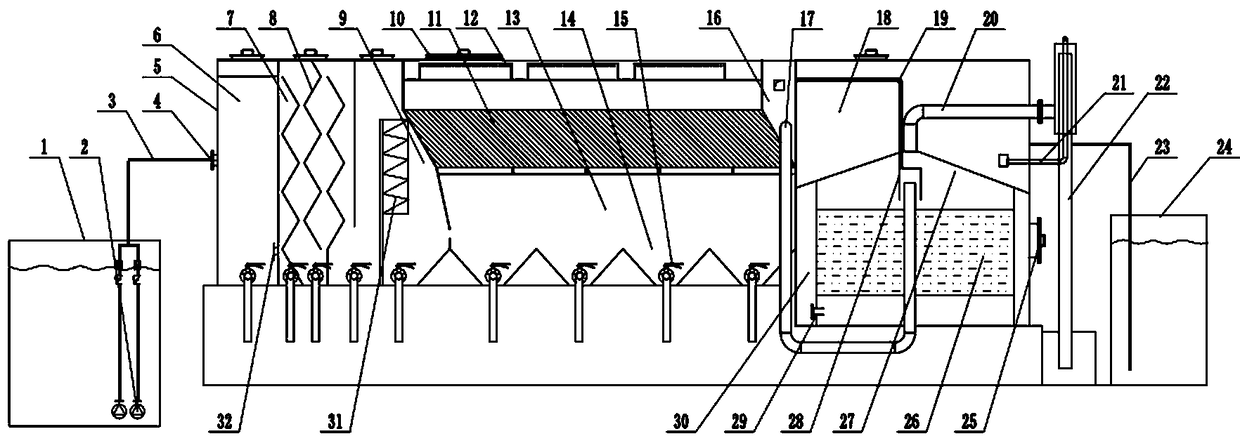

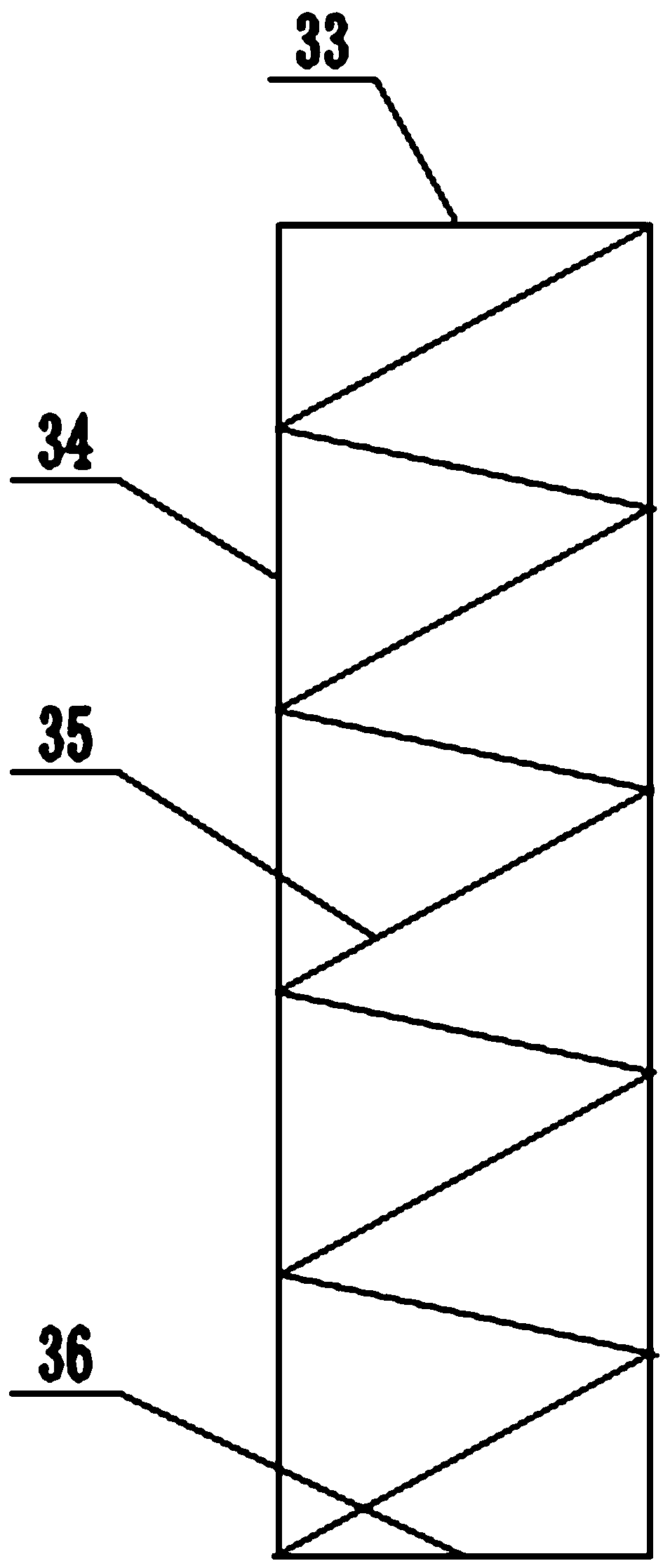

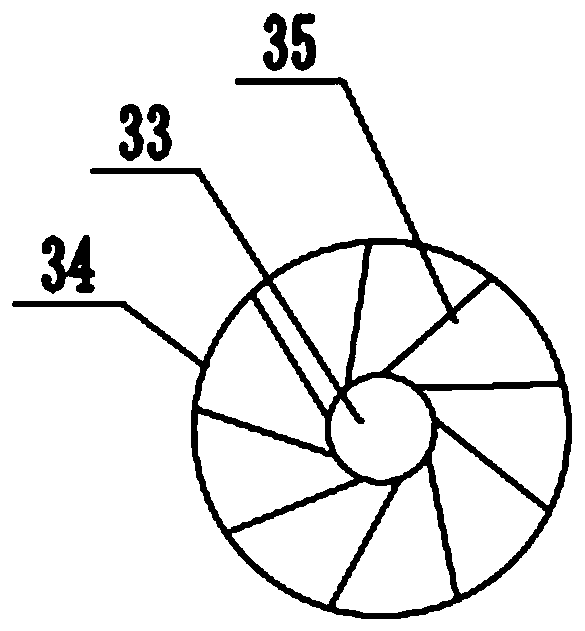

[0030] Boiler ash water treatment and recycling device, which includes a box shell 5, the box shell 5 is provided with a primary reaction zone 6, a secondary reaction zone 7, a tertiary reaction zone 9, a precipitation zone 13 and a clean water zone 18, Described primary reaction zone 6 is provided with water inlet 4, and the bottom of primary reaction zone 6 is provided with the water outlet 32 that communicates with secondary reaction zone 7; Described secondary reaction zone 7 and tertiary reaction zone 9 The upper part is connected, and the lower part of the tertiary reaction zone 9 is connected with the sedimentation zone 13; the lower part of the sedimentation zone 13 is provided with a mud collection area 14, and the mud collection area 14 is equipped with a mud discharge pipe 15; the upper part of the mud collection area 14 is provided with an inclined pipe sedimentation area 11. An overflow tank 12 is arranged on the upper part of the inclined pipe sedimentation zone...

Embodiment 2

[0041] Boiler ash water treatment and recycling device, which includes a box shell 5, the box shell 5 is provided with a primary reaction zone 6, a secondary reaction zone 7, a tertiary reaction zone 9, a precipitation zone 13 and a clean water zone 18, Described primary reaction zone 6 is provided with water inlet 4, and the bottom of primary reaction zone 6 is provided with the water outlet 32 that communicates with secondary reaction zone 7; Described secondary reaction zone 7 and tertiary reaction zone 9 The upper part is connected, and the lower part of the tertiary reaction zone 9 is connected with the sedimentation zone 13; the lower part of the sedimentation zone 13 is provided with a mud collection area 14, and the mud collection area 14 is equipped with a mud discharge pipe 15; the upper part of the mud collection area 14 is provided with an inclined pipe sedimentation area 11. An overflow tank 12 is arranged on the upper part of the inclined pipe sedimentation zone...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com