Preparation process of metal filter layer and filter element

A technology of metal filtration and preparation process, which is applied in the field of filtration, can solve the problems of thick composite filter elements, high reject rate, unevenness, etc., and achieve the effect of high bonding strength, high yield, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

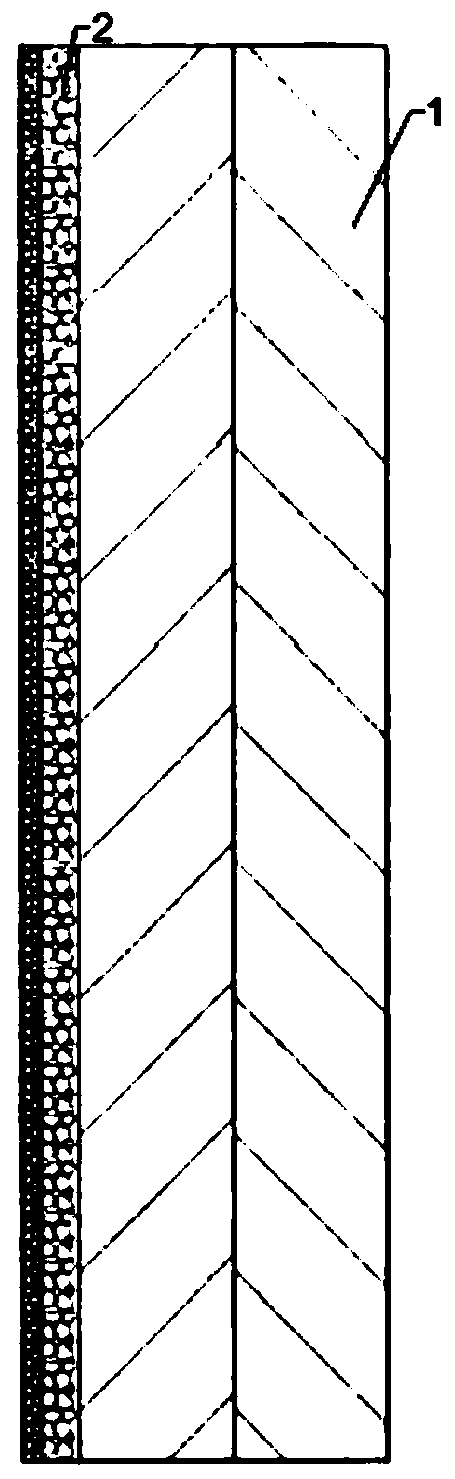

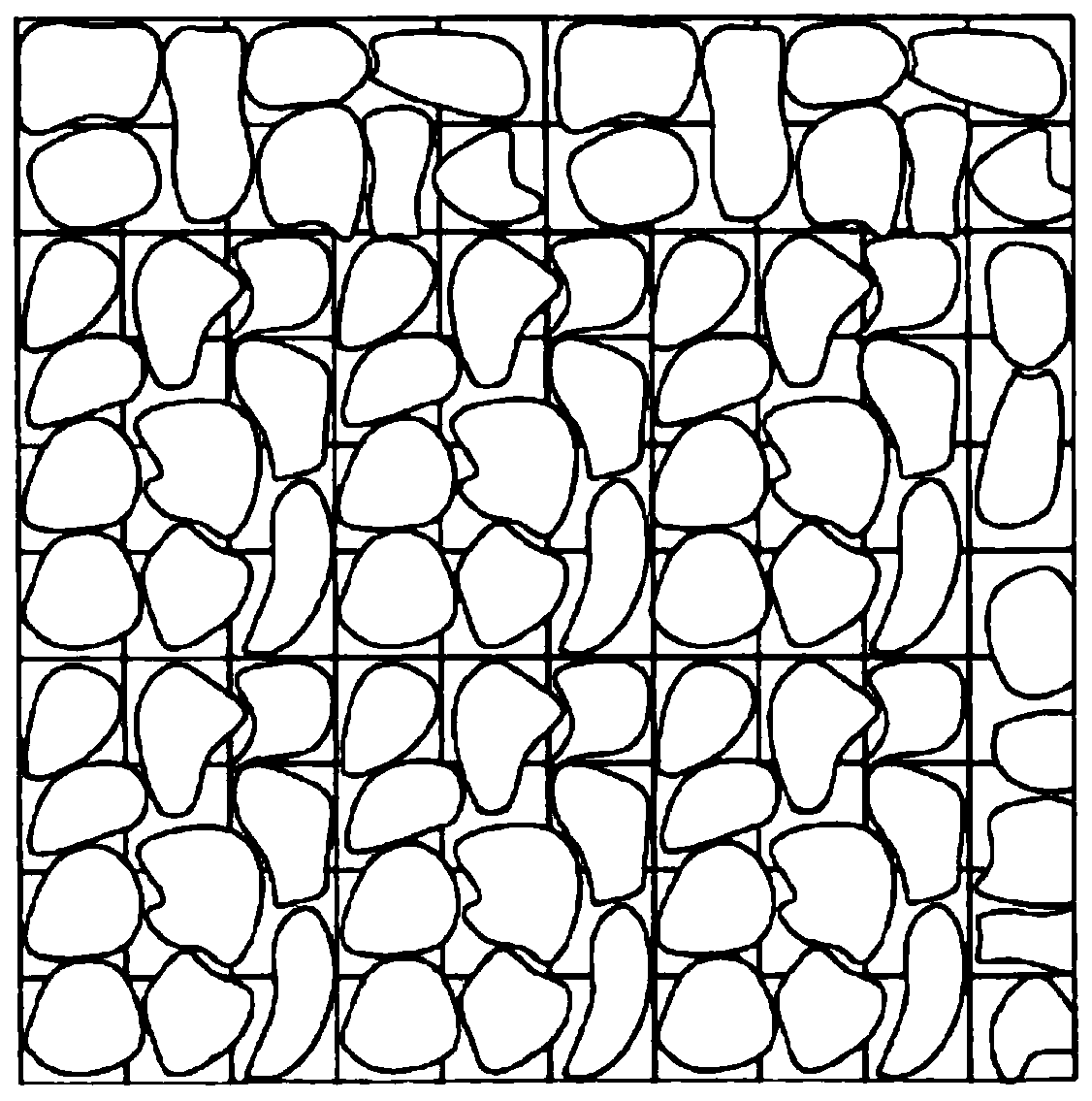

[0034] B. Arrange the metal mesh, roll two 1000x1000mm 12x64 purpose 316L metal mat mesh on a two-roll rolling mill and stack them vertically according to the lines, and then put them in a vacuum sintering furnace for sintering at a temperature of 1300°C , 1.0×10 1 pa, the holding time is 3.5 hours, and after the sintering is completed, use a two-roll rolling mill to flatten to a set thickness of 1.6mm to obtain a support layer, and then use a bending die to make the support layer into a shape with an outer diameter of 25mm and a length of 1000mm Round tube shape.

[0035] C. Coating the metal powder slurry on the support layer of the circular tube, the metal powder slurry is prepared as follows: 1000 grams of 316L water atomized stainless steel powder particles with a particle size of 600 / 800 mesh, 2000 grams of purified water and 6 grams of Carbomer 941 Mix and stir evenly to obtain a suspension slurry, and then use a spray gun to evenly coat the prepared suspension slurry ...

Embodiment 2

[0037] B. Arrange the metal mesh, roll two 1000x1000mm 12x64 purpose 316L metal mat mesh on a two-roll rolling mill in turn and stack them vertically according to the lines, and then sinter in a vacuum sintering furnace at a sintering temperature of 1320°C , 1.0×10 -2 pa, the holding time is 2.5 hours, and after the sintering is completed, use a two-roll rolling mill to flatten to a set thickness of 1.6mm to obtain a support layer, and then use a bending die to make the support layer with an outer diameter of 30mm and a length of 1000mm. Round tube shape.

[0038] C. Coating the metal powder slurry on the support layer of the circular tube, the metal powder slurry is prepared as follows: 600 grams of 316L water atomized stainless steel powder particles with a particle size of 800 / 1000 mesh, 1800 grams of pure water and 5.4 grams of Carbomer 941 Mix and stir evenly to obtain a suspension slurry, and then use a spray gun to evenly coat the prepared suspension slurry on the oute...

Embodiment 3

[0040] B. Arrange the metal mesh, roll two 1000x1000mm 12x64-mesh 316L metal mat-shaped mesh on a two-roll rolling mill in turn and stack them vertically according to the lines, and then put them in a vacuum sintering furnace for sintering at a sintering temperature of 1200°C , 2pa, and the holding time is 4.5 hours. After sintering, use a two-roll rolling mill to flatten to a set thickness of 1.6mm to obtain a support layer, and then use a bending die to make the support layer with an outer diameter of 25mm and a length of 1000mm. Round tube shape.

[0041]C. Coating the metal powder slurry on the support layer of the round tube, the metal powder slurry is prepared as follows: 500 grams of 500 / 700 mesh 316L water atomized stainless steel powder particles, 1500 grams of purified water and 4.5 grams of Carbomer 941 Mix and stir evenly to obtain a suspension slurry, and then use a spray gun to evenly coat the prepared suspension slurry on the outer surface of the round tube supp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com