Upflowing and compressable filtration system

A filtration system and water filtration technology, applied in the direction of loose filter material filter, filtration separation, gravity filter, etc., can solve the problems of large floor space, unsuitable for large-scale municipal water treatment, membrane pollution, etc. The effect of floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

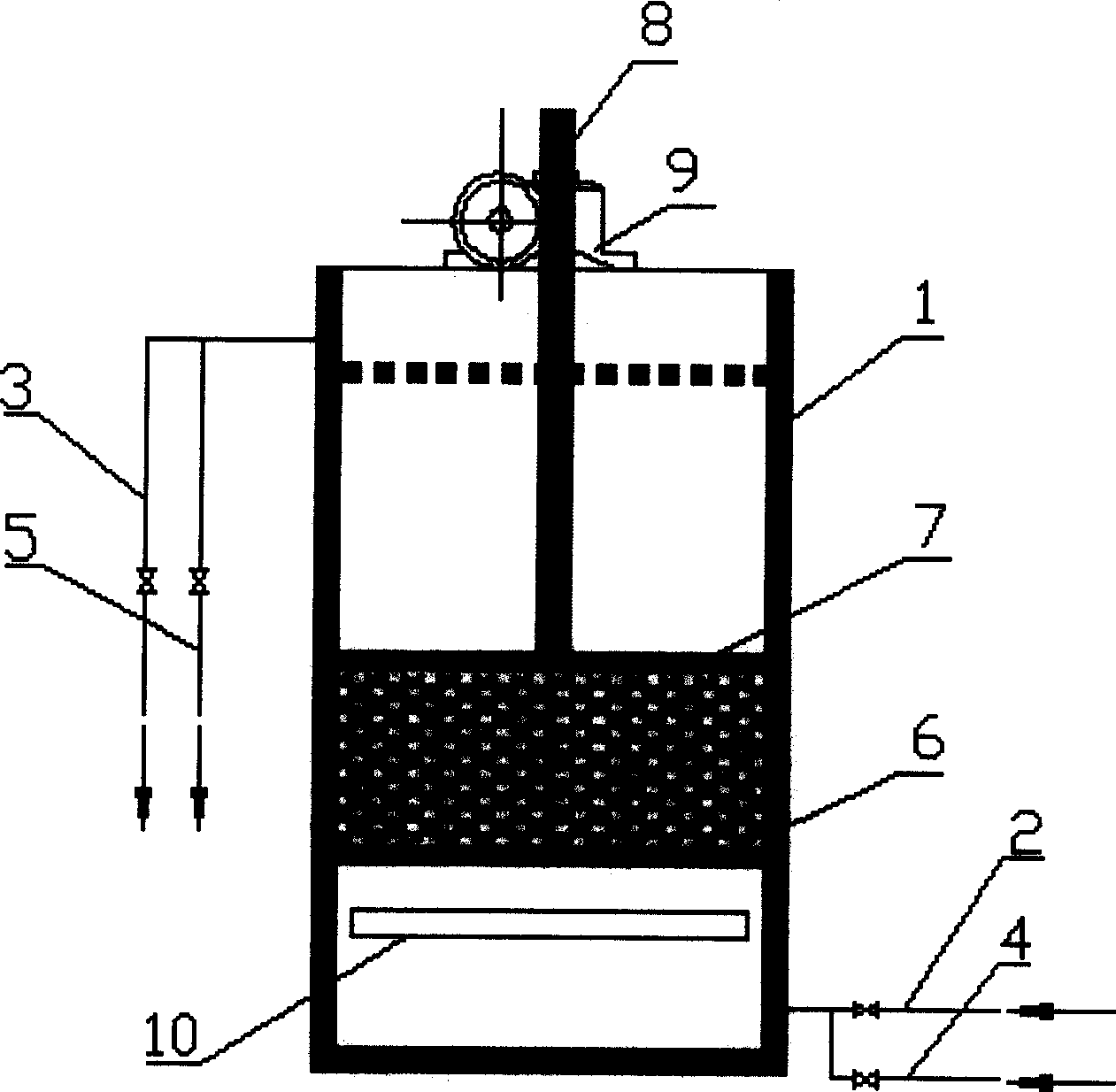

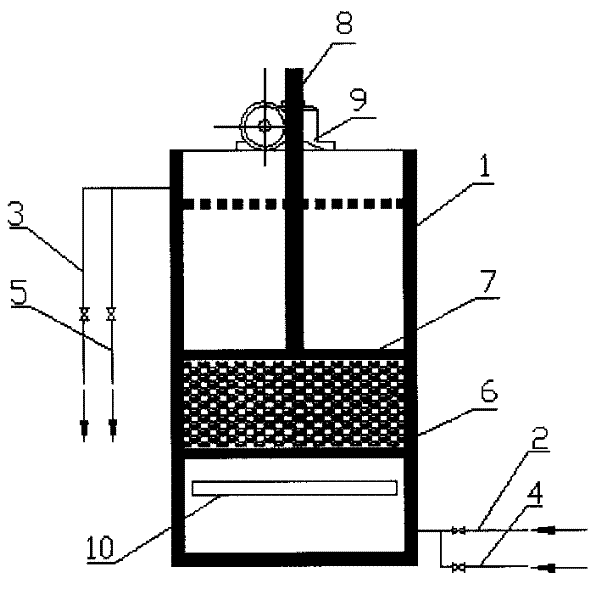

[0013] see figure 1 , an upward flow compressible filter system, the water filter tank 1 adopts the form of a filter tank, and its shape is a rectangular cylinder or a square cylinder, which is built from common ingredients in civil engineering. The filter material adopts soft filter material such as fiber balls, and a porous plate 6 that can block the filter material and a porous press plate 7 that can compress the filter material are placed in the water filter tank 1. The porous press plate 7 and the transmission shaft 8 that supports its up and down movement The transmission shaft 8 is connected with the transmission mechanism 9 fixed on the outer top of the water filter tank 1. The transmission mechanism 9 adopts the transmission form of a worm gear and a worm screw. The water inlet pipe 2 is arranged at the lower end of the water filter tank 1. The water outlet pipe 3 is placed on the upper end of the water filter tank 1, and an air diffuser 10 that can be connected to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com