Preparation method of superhigh temperature filter material

A filter material and ultra-high temperature technology, applied in the field of ultra-high temperature filter material preparation, can solve the problems of unsatisfactory physical and chemical indicators such as high temperature resistance, chemical resistance, structural stability, etc., and achieve shortened drying time, outstanding filtration performance, The effect of improving temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

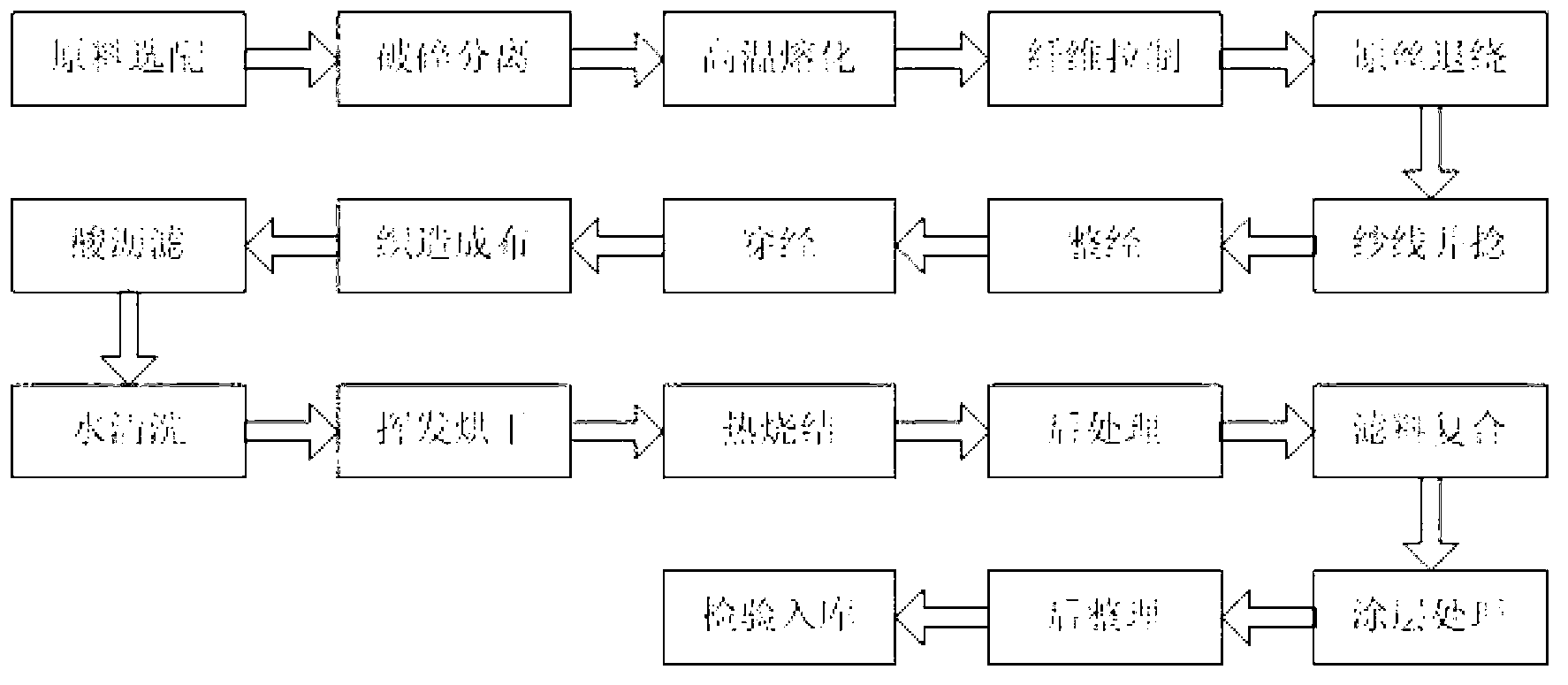

Method used

Image

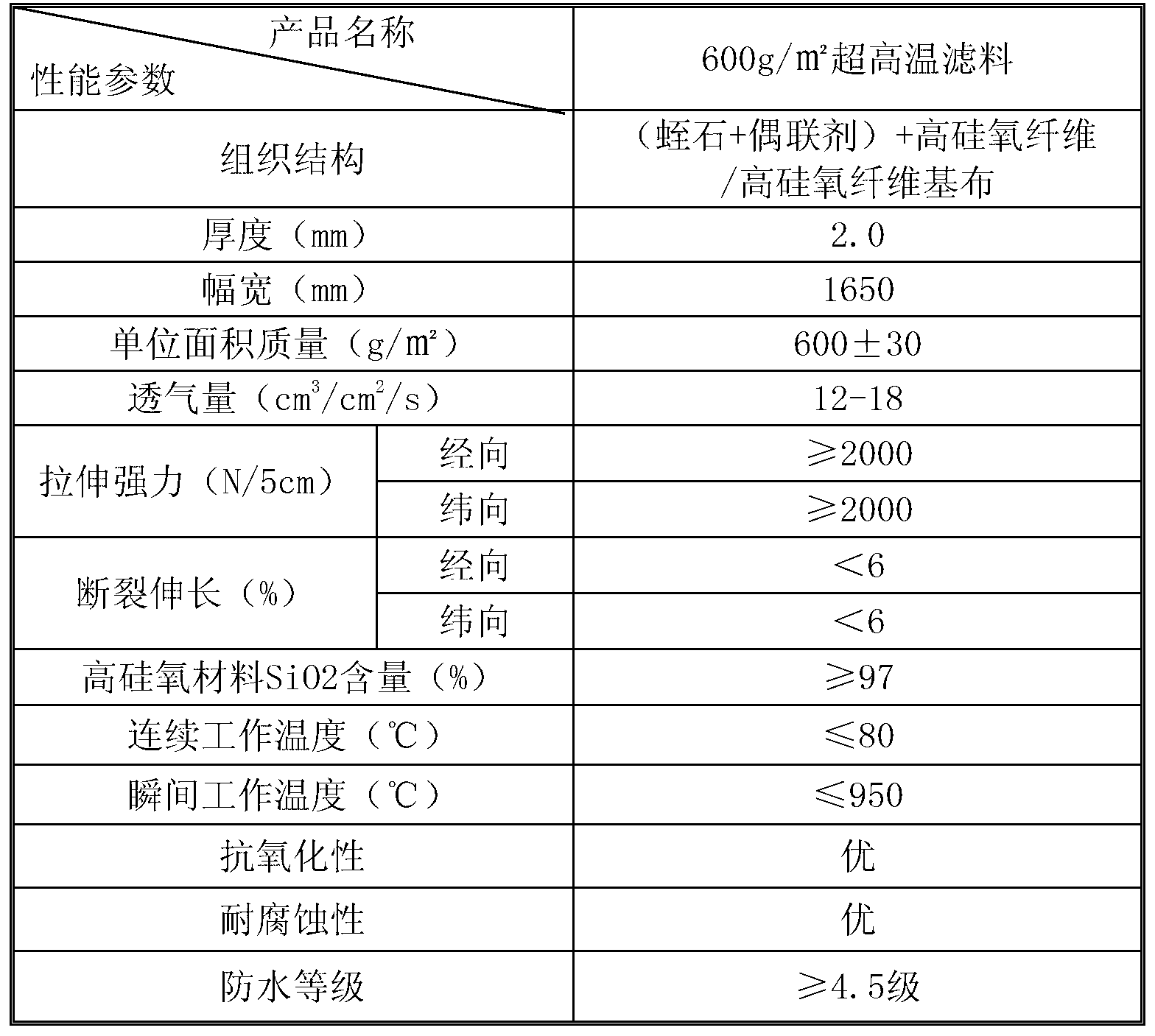

Examples

Embodiment 1

[0030] (1) Put the selected three-component sodium borosilicate glass fiber product (ie glass fiber raw material) into the wire drawing furnace for high temperature melting, the melting temperature is 1420 ° C; The produced high silica fiber is coated with monofilament and passed through a strong cooling device to ensure that the fracture rate of monofilament is within 1%.

[0031] (2) Make part of the glass fiber staple fiber into glass fiber woven fabric.

[0032] (3) Place glass fiber staple fibers and glass fiber woven fabrics (hereinafter collectively referred to as "glass fiber products") in an acid leaching tank for acid leaching treatment. Acid leaching formula: concentrated hydrochloric acid 10wt%, silane coupling Agent 2wt%, the balance of distilled water; constant temperature acid leaching temperature is controlled at 85 ℃, and treated for 1.5 hours. The chemical formula of acid leaching is optimized, and after many tests, it is determined that the coupling agent a...

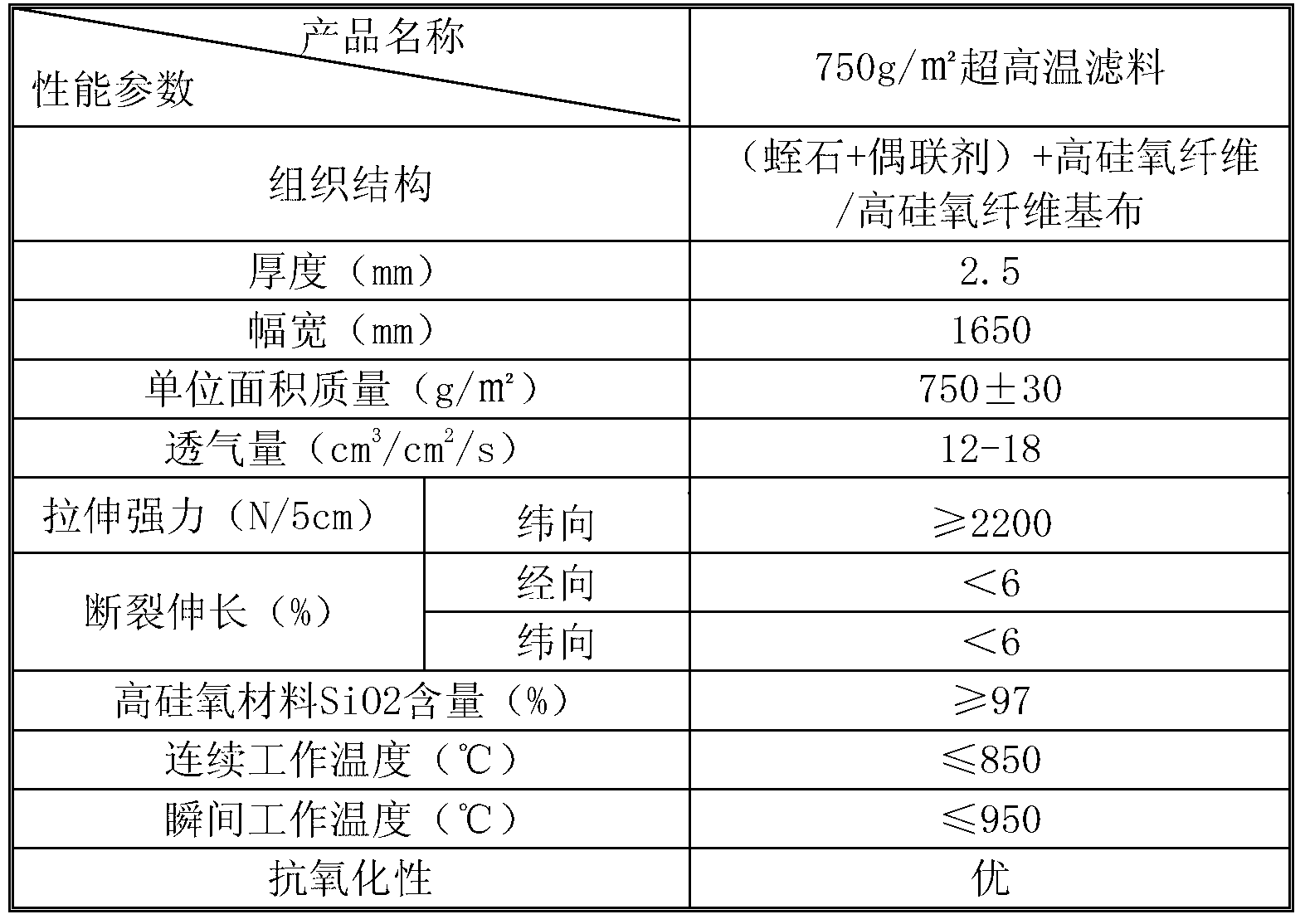

Embodiment 2

[0043] (1) Put the selected three-component sodium borosilicate glass fiber product into the wire drawing kiln for high-temperature melting, the melting temperature is 1480 ° C; The fiber is monofilament coated and passed through a strong cooling device to ensure that the fracture rate of the monofilament is within 1%.

[0044] (2) Weave part of the glass fiber into glass fiber woven cloth.

[0045] (3) Arrange the glass fiber short fiber and the glass fiber weaving in the acid leaching tank for acid leaching treatment, acid leaching formula: concentrated hydrochloric acid 20wt%, silane coupling agent 5wt%, distilled water balance; constant temperature The acid leaching temperature is controlled at 98°C, and the treatment is 3.5 hours;

[0046] (4) Rinse the acid-leached glass fiber product with warm water to remove residual acid on the surface of the product. The preferred water temperature is 50°C, then soak it in a circulating filter tank, and use flowing warm water to cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com