High-strength high-performance filter element

A high-performance, high-strength technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of reducing the service life of the transmission system, reducing the filtration precision of the filter, the impact of filtration precision and efficiency, etc. , to achieve the effect of increasing the flow performance, increasing the filter contact area, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below with reference to the drawings and embodiments.

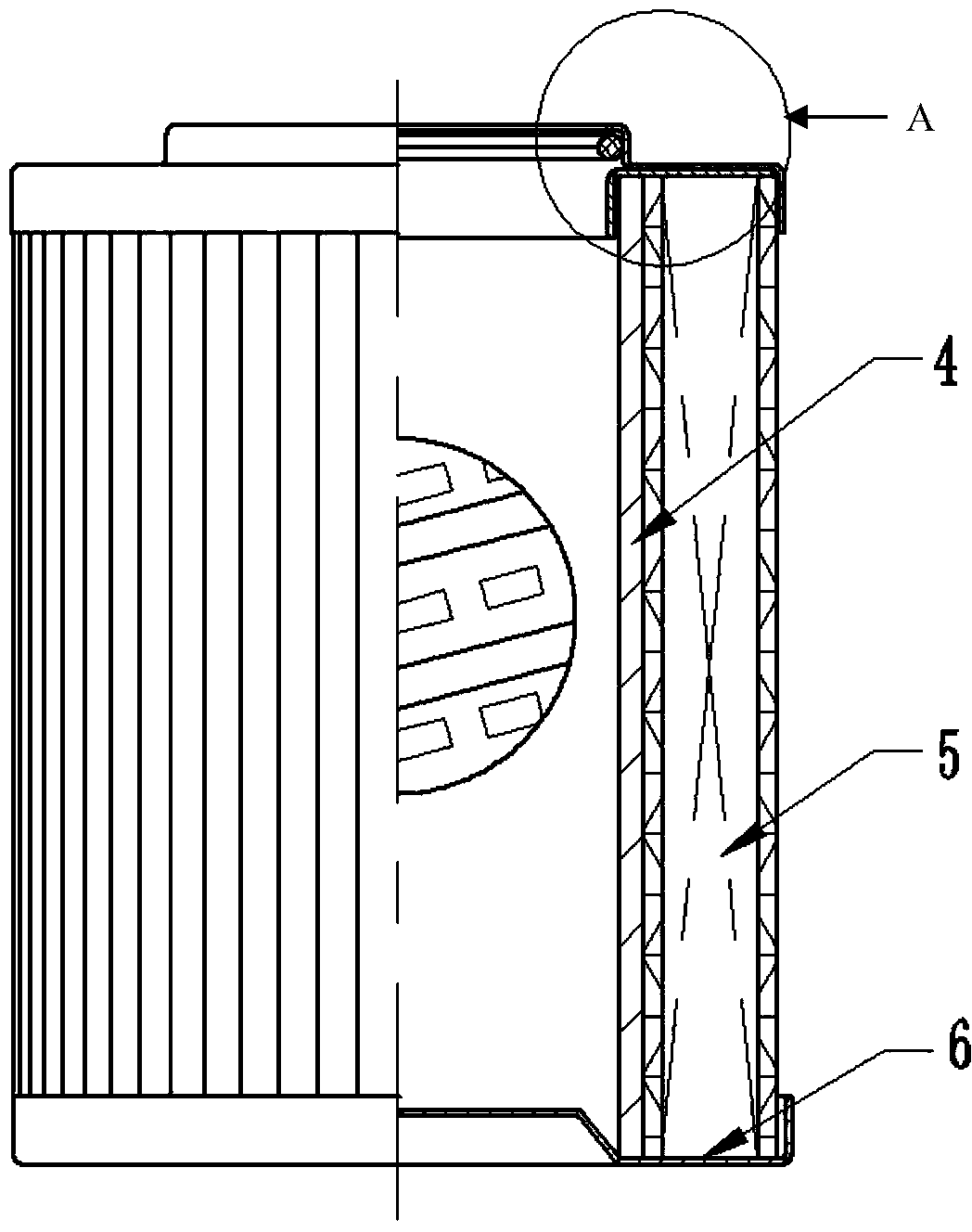

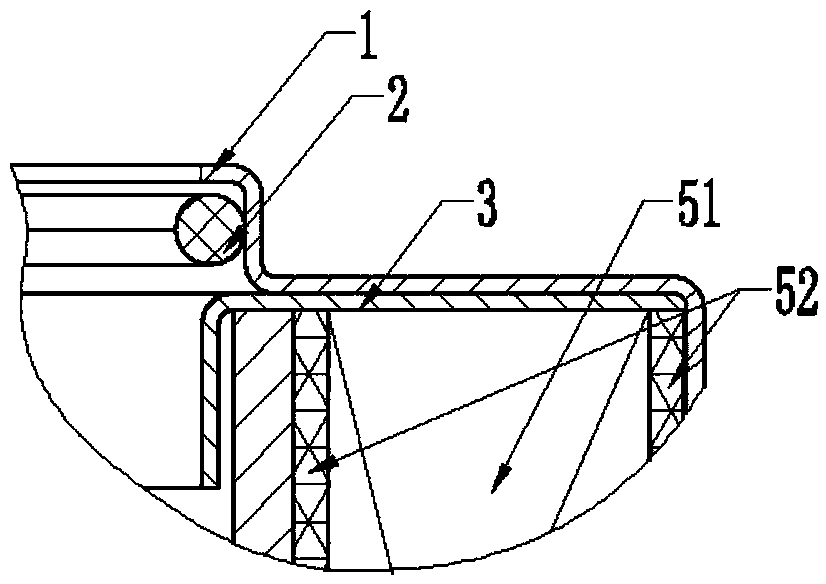

[0032] Such as Figure 1 ~ Figure 4 As shown, a high-strength and high-performance filter element includes an upper end cover (1), a lower end cover (6), a center tube (4), and a filter cartridge (5) arranged on the periphery of the center tube (4). The upper end cover ( 1) and the lower end caps (6) are arranged at both ends of the filter cartridge (5) and the central tube (4), the filter cartridge (5) includes a wave-shaped filter layer (51) and a wave-shaped metal mesh (52); The wave-shaped metal mesh (52) is provided on both sides of the wave-shaped filter layer (51);

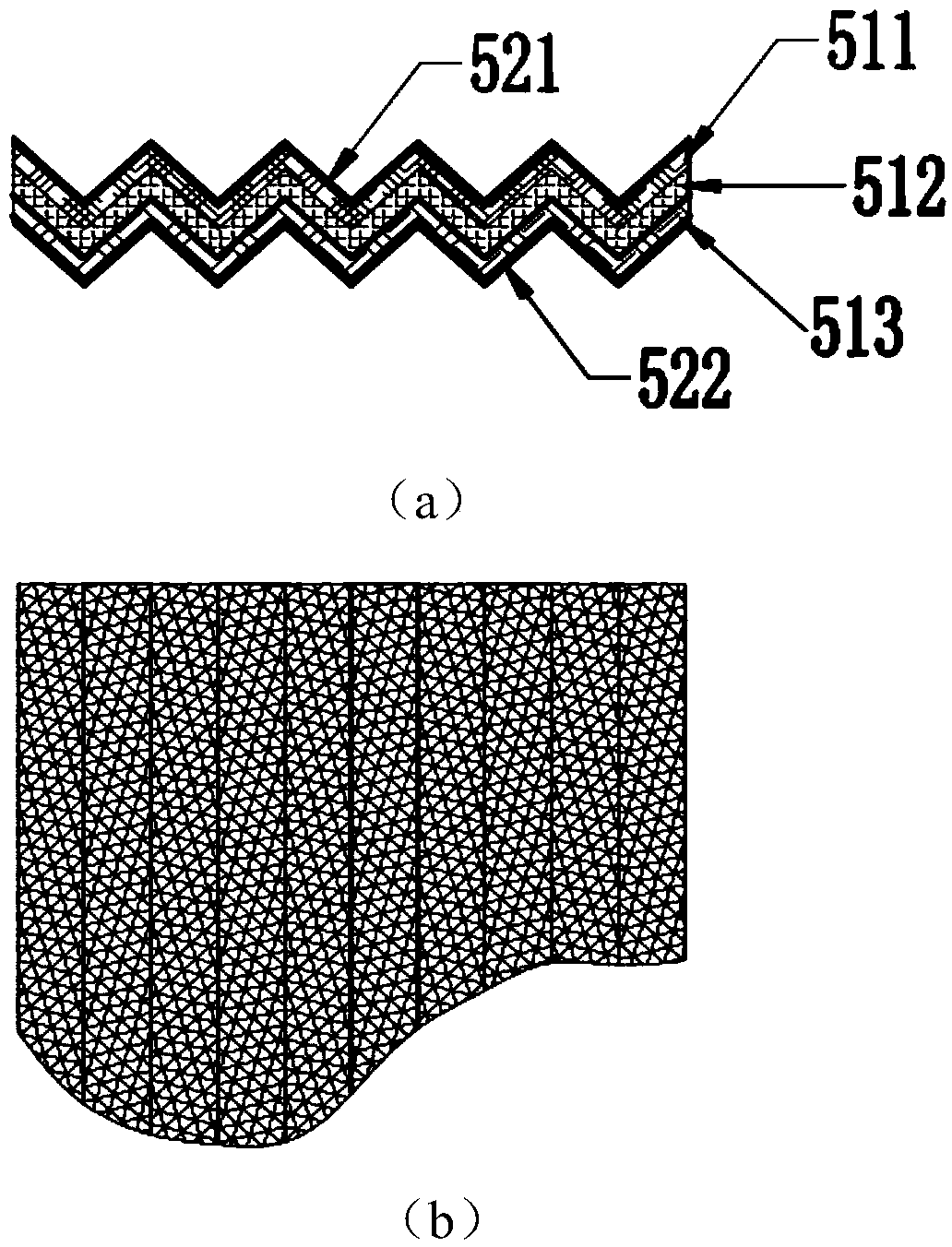

[0033] The filter layer (51) is composed of a glass fiber felt layer (511), a glass fiber filter paper layer (512) and a non-woven fabric layer (513) stacked in sequence; the non-woven fabric layer (513) is close to the central tube (4 ); The wave-shaped metal mesh (52) includes a wave-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com