Efficient backwash-free high-precision filter

A backwashing and high-precision technology, which is applied in the direction of fixed filter elements, filtration separation, chemical instruments and methods, etc., can solve the problems of difficult to thoroughly clean the filter material, easy to hold dirt, high precision requirements, etc., to reduce cleaning Difficulty and maintenance cost, protection of filter structure, effect of ensuring filter accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Terms such as "upper", "inner", "middle", "left", "right" and "one" quoted in this specification are only for the convenience of description, and are not used to limit the scope of the present invention. The scope of implementation and the change or adjustment of its relative relationship shall also be regarded as the scope of implementation of the present invention without substantive changes in technical content.

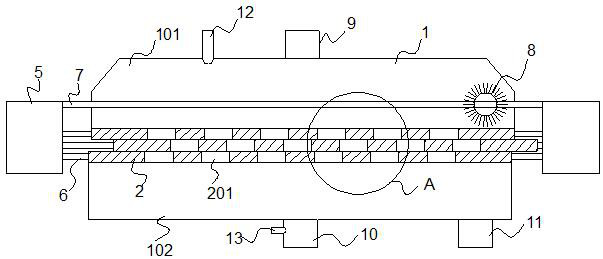

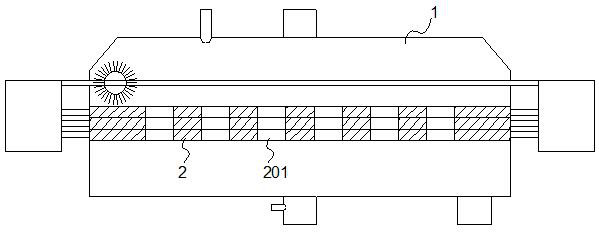

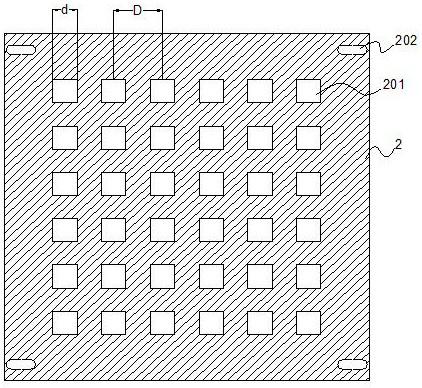

[0031] Such as figure 1 , 6 As shown, a high-efficiency backwash-free high-precision filter includes a housing 1 and a filter mechanism installed in the housing 1. The filter mechanism includes more than three layers of perforated plates 2, and the perforated plates 2 are evenly opened with apertures. For filter holes 201 larger than the diameter of the largest particles to be filtered, the distance D between the centers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com