Preparation method of kieselguhr ceramic filter cartridge

A technology of ceramic filter elements and diatomite, which is applied in the field of ceramic filter elements, can solve the problems of low production efficiency, complicated preparation process, and low filtration precision, and achieve the effects of avoiding damage to the human body, improving market competitiveness, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below.

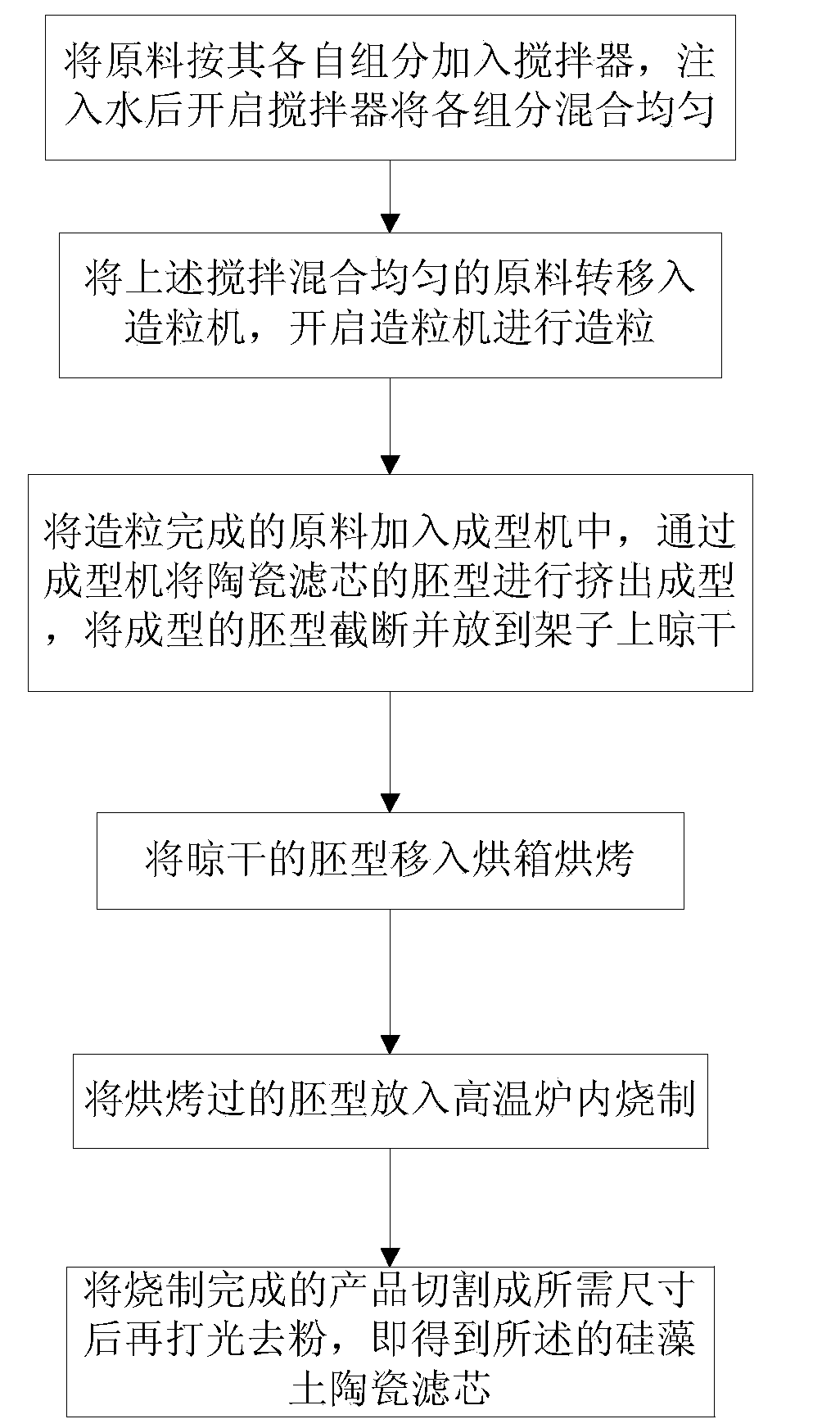

[0018] This embodiment provides a method for preparing a diatomite ceramic filter element, comprising the following steps:

[0019] (1) The mass ratio of each component is 95% of diatomite, 2% of fluxing pore-expanding agent, 2.5% of adhesive, and 0.5% of embryo body reinforcing agent to weigh the raw materials, and add the weighed raw materials into the mixer, After injecting water, turn on the agitator to mix the components evenly;

[0020] (2) The above-mentioned stirred and mixed raw materials are transferred into the granulator, and the granulator is opened for granulation;

[0021] (3) Add the finished raw material of granulation in the molding machine, extrude the blank of the ceramic filter element by the molding machine, cut off the molded blank and put it on the shelf to dry;

[0022] (4) Move the above-mentioned air-dried embryo into an oven and bake at 80°C for 1 day;

[0023] (5) Put the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com