Nanofiber composite air filter paper and production method thereof

A nanofiber, air filter paper technology, applied in the post-treatment modification of cellulose pulp, filter paper, special paper, etc., can solve the problems of large coating amount of resin layer, affecting the air permeability, filtration efficiency, and thickness of air filter paper, etc. To achieve the effect of high air permeability and filtration efficiency, high strength and improving filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

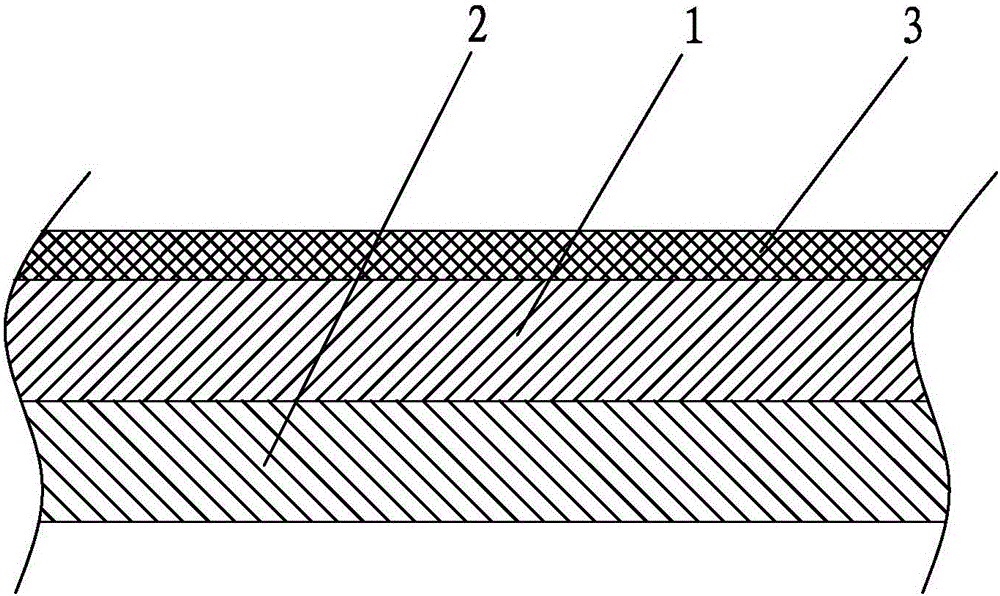

[0032] like figure 1 As shown, a nanofiber composite air filter paper includes an upper filter layer 1, a lower filter layer 2 and a nanocellulose composite coating 3 coated on the upper surface of the upper filter layer.

[0033] Wherein, the thickness of the upper filter layer is 0.11-0.12mm, and the thickness of the lower filter layer is 0.18-0.19mm.

[0034] A preparation method of nanofiber composite air filter paper, carried out according to the following steps:

[0035] a. Preparation of the base paper for the upper filter layer: 30 parts of mercerized fiber, 15 parts of sisal fiber, and 15 parts of horn gourd fiber are mixed and beaten, the concentration of the slurry is 2.2wt%, and the degree of beating until the slurry is 13° After SR, refining is carried out until the degree of beating is 18°SR, and slurry a is obtained; 1 part of ethylene glycol diglycidyl ether is added to the slurry a, and the slurry b is obtained after stirring evenly; Add 0.3 parts of sodium ...

Embodiment 2

[0042] A nanofiber composite air filter paper comprises an upper filter layer, a lower filter layer and a nanocellulose composite coating on the upper surface of the upper filter layer.

[0043] Wherein, the thickness of the upper filter layer is 0.10-0.11 mm, and the thickness of the lower filter layer is 0.18-0.19 mm.

[0044] A preparation method of nanofiber composite air filter paper, carried out according to the following steps:

[0045] a. Preparation of the base paper for the upper filter layer: 20 parts of mercerized fiber, 10 parts of sisal fiber, and 10 parts of horn gourd fiber are mixed and beaten, the concentration of the slurry is 1.9wt%, and the degree of beating until the slurry is 12° After SR, refine the pulp again until the degree of beating is 16°SR to obtain slurry a; add 0.5 parts of ethylene glycol diglycidyl ether to the slurry a, and stir evenly to obtain slurry b; Add 0.2 parts of sodium hexametaphosphate to the slurry b, add water to adjust the con...

Embodiment 3

[0052] A nanofiber composite air filter paper comprises an upper filter layer, a lower filter layer and a nanocellulose composite coating on the upper surface of the upper filter layer.

[0053] Wherein, the thickness of the upper filter layer is 0.14-0.15mm, and the thickness of the lower filter layer is 0.19-0.20mm.

[0054] A preparation method of nanofiber composite air filter paper, carried out according to the following steps:

[0055] a. Preparation of the base paper for the upper filter layer: 40 parts of mercerized fiber, 20 parts of sisal fiber, and 20 parts of horn gourd fiber are mixed and beaten, the concentration of the slurry is 2.5wt%, and the degree of beating until the slurry is 14° After SR, refine the pulp again until the degree of beating is 20°SR to obtain slurry a; add 1.5 parts of ethylene glycol diglycidyl ether to the slurry a, and stir evenly to obtain slurry b; Add 0.4 parts of sodium hexametaphosphate to the slurry b, add water to adjust the conce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com