Nuclear pore filter membrane with compound pore passage and preparation method of nuclear pore filter membrane

A kind of nuclear pore filter membrane and composite technology, which is applied in the field of nuclear pore filter membrane preparation, can solve the problems of inability to conduct, the tapered hole cannot be made a large taper, and the inner pore diameter cannot be controlled, so as to improve the filtration speed, The effect of maintaining the filtering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

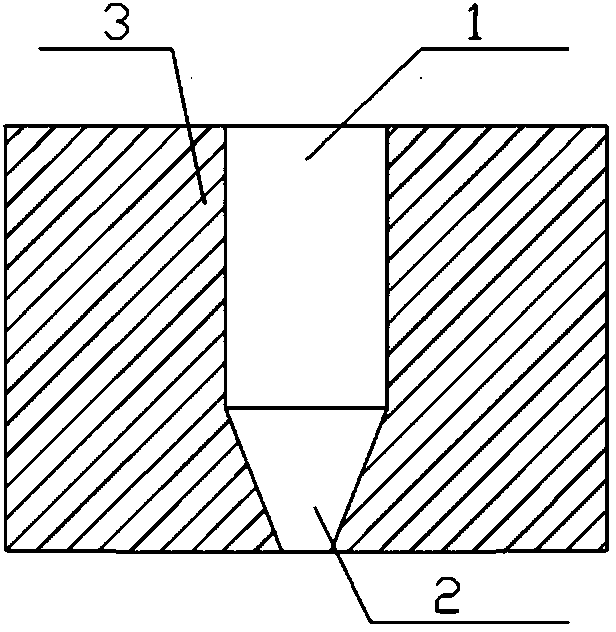

[0029] Example 1: see figure 1 , a composite pore nuclear pore filter membrane, which includes nuclear pores irradiated with heavy ions on a polymeric film 3, the film is PET, and the thickness is 10 μm. The nuclear pore channel is a cone / column compound type, the upper part of the nuclear pore is a cylindrical hole 1, and the lower part is a conical hole 2. The largest diameter of the cone is connected to the cylinder. The diameter of the cylindrical hole 1 is 2 μm, and the minimum diameter of the conical hole 2 is 400 nm.

Embodiment 2

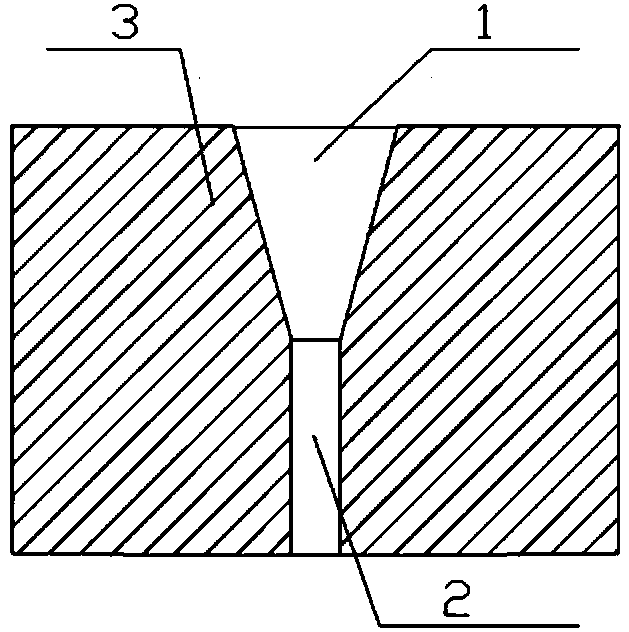

[0030] Example 2: see figure 2 , a composite pore nuclear pore filter membrane, which includes nuclear pores irradiated with heavy ions on a polymeric film 3, the film is PET, and the thickness is 10 μm. The nuclear pore channel is a cone / column compound type, the upper part of the nuclear pore is a conical hole 1, and the lower part is a cylindrical hole 2. The smallest diameter of the cone is connected to the cylinder. The maximum diameter of the conical hole 1 is 2 μm, and the diameter of the cylindrical hole 1 is 400 nm.

Embodiment 3

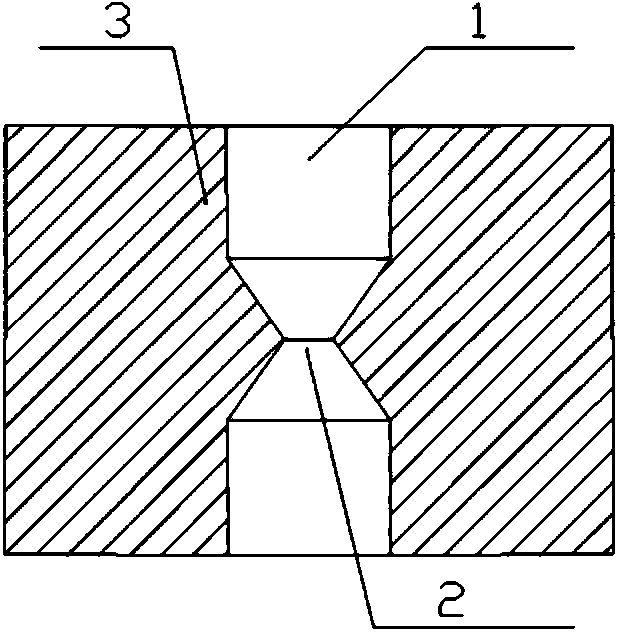

[0031] Embodiment 3: see image 3, a cone / column composite pore nuclear pore filter membrane, which includes nuclear pores irradiated with heavy ions on a polymeric film 3, the film is PET, and the thickness is 10 μm. The nuclear pore channel is a cone / column compound type, with a symmetrical structure up and down. The two sides of the film are cylindrical holes 1, and the middle is a conical hole 2; the largest hole diameter of the cone is connected with the cylinder. The diameter of the cylindrical hole 1 is 2 μm, and the minimum diameter of the conical hole 2 is 400 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com