Vacuumizing stirring machine

A vacuum pumping and blender technology, which is applied in the field of food processing, can solve the problems of poor taste, inconvenient use, and mouth-to-mouth drinking, and achieve the effect of powerful function, convenient portability, and guaranteed taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

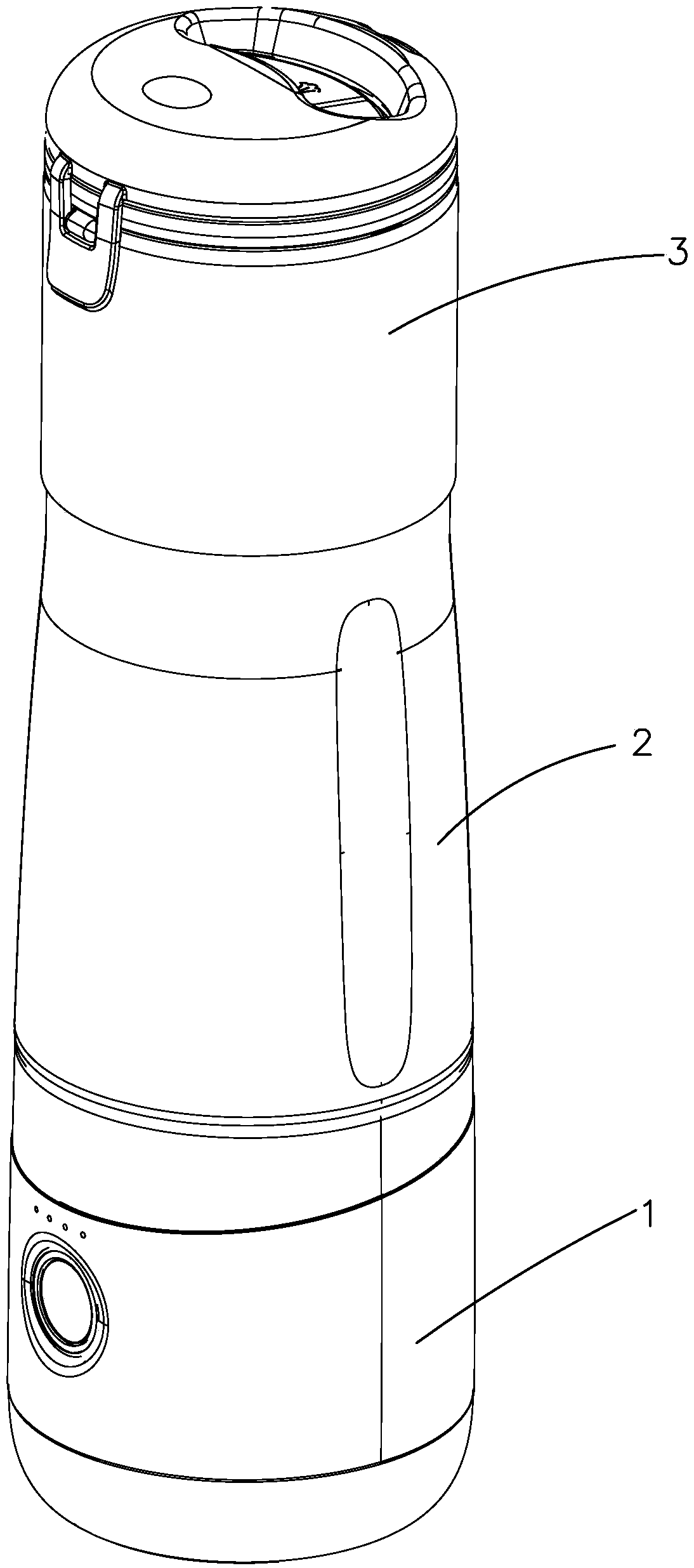

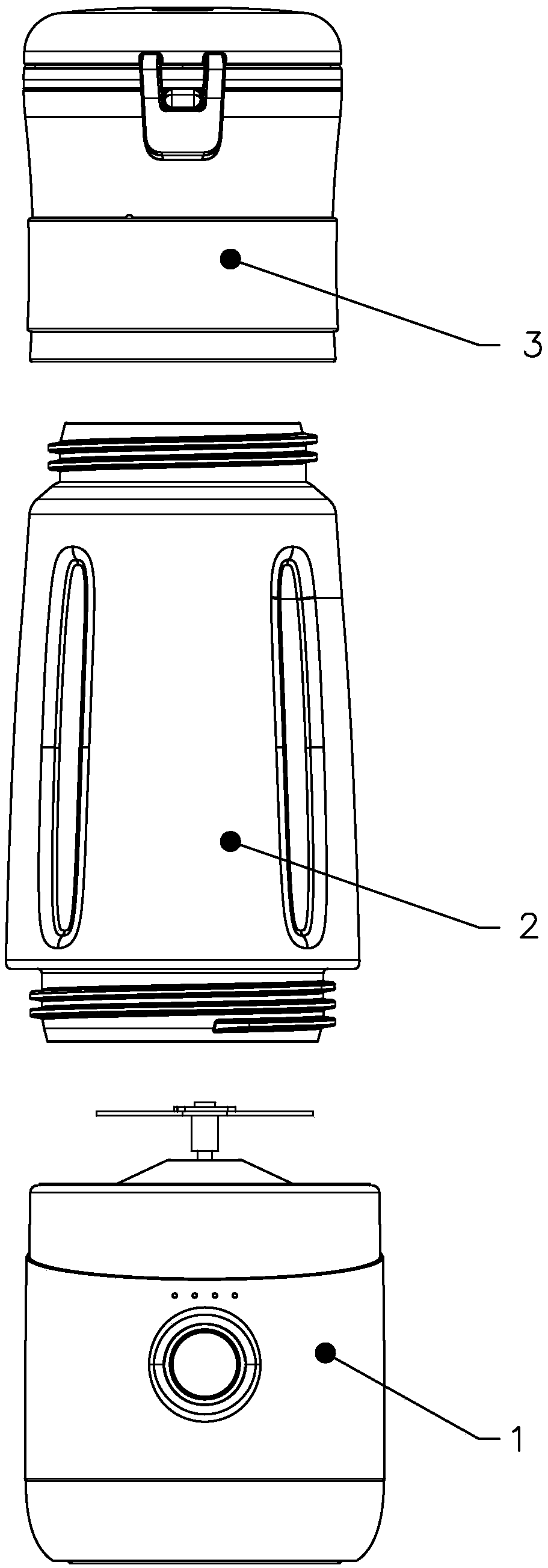

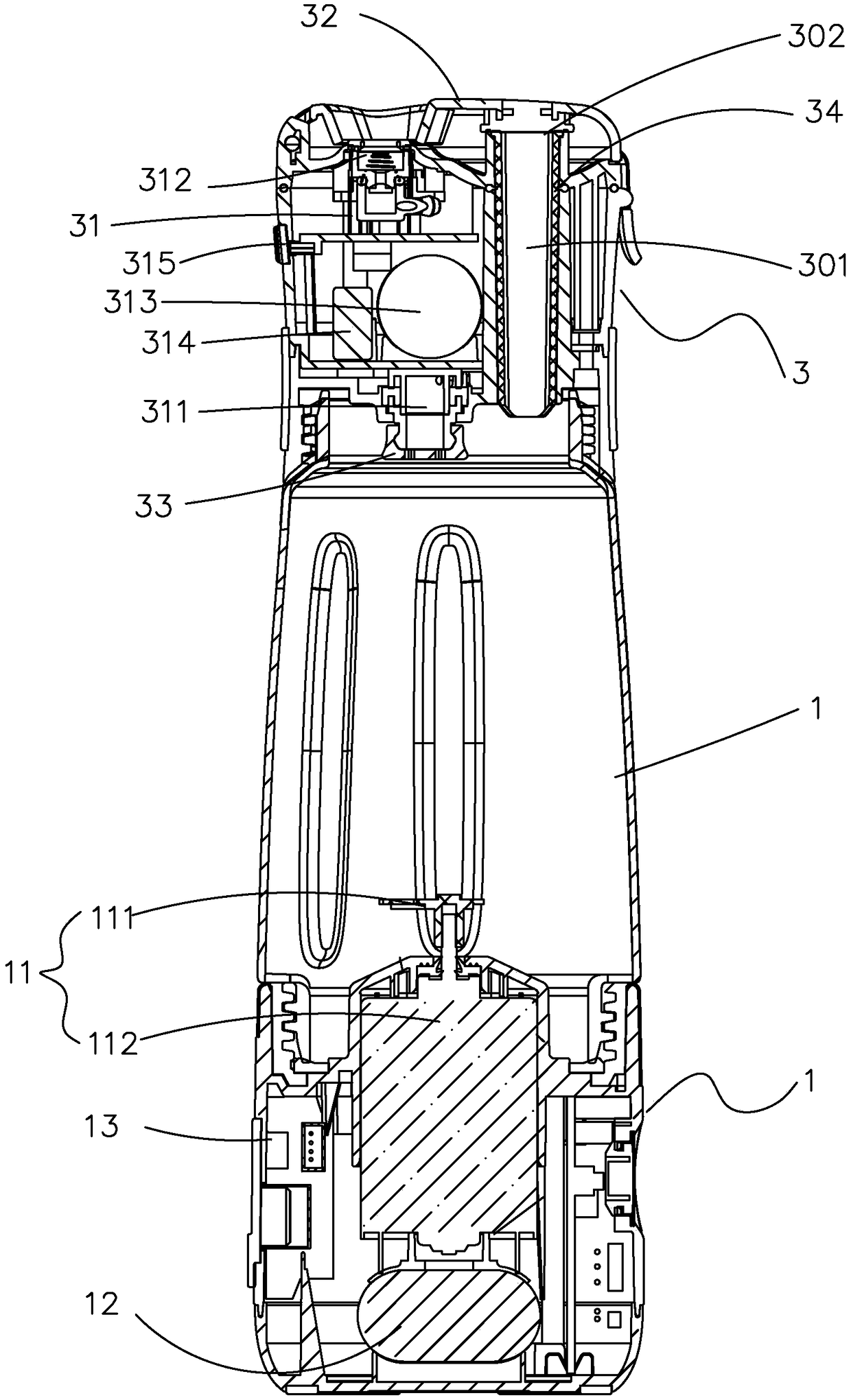

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 13 and Figure 14 As shown, a vacuum mixer includes an organic base 1, and the base 1 is provided with a stirring cup 2 and a stirring assembly 11 for stirring the ingredients in the stirring cup 2. The upper end of the stirring cup 2 is sealed with a cup upper seat 3, and the cup The upper base 3 is provided with a vacuum device 31 that can evacuate the stirring cup 2, and the cup upper base 3 is also provided with a liquid outlet channel 301 that communicates with the stirring cup 2. The liquid outlet channel 301 has a liquid outlet that can be directly drunk by the user. mouth 302, you can drink with your mouth without removing the cup top seat, and the liquid outlet channel 301 is provided with a sealing device for sealing the liquid outlet channel 301 when the vacuum device 31 is vacuumed, so as to ensure that the device is sealing effect. In the vacuum-pumping mixer of the present inv...

Embodiment 2

[0045] Such as figure 1 , figure 2 , image 3 , Figure 6 , Figure 7 , Figure 13 and Figure 14 As shown, a vacuum mixer includes an organic base 1, and the base 1 is provided with a stirring cup 2 and a stirring assembly 11 for stirring the ingredients in the stirring cup 2. The upper end of the stirring cup 2 is sealed with a cup upper seat 3, and the cup The upper base 3 is provided with a vacuum device 31 that can evacuate the stirring cup 2, and the cup upper base 3 is also provided with a liquid outlet channel 301 that communicates with the stirring cup 2. The liquid outlet channel 301 has a liquid outlet that can be directly drunk by the user. The port 302, the liquid outlet channel 301 is provided with a sealing device for sealing the liquid outlet channel 301 when the vacuum pumping device 31 is vacuumed. In the vacuum-pumping mixer of the present invention, a stirring cup is arranged on the machine base, and a cup upper seat is sealed and connected to the st...

Embodiment 3

[0055] Such as figure 1 , figure 2 , image 3 , Figure 8 , Figure 9 , Figure 13 and Figure 14 As shown, a vacuum mixer includes an organic base 1, and the base 1 is provided with a stirring cup 2 and a stirring assembly 11 for stirring the ingredients in the stirring cup 2. The upper end of the stirring cup 2 is sealed with a cup upper seat 3, and the cup The upper base 3 is provided with a vacuum device 31 that can evacuate the stirring cup 2, and the cup upper base 3 is also provided with a liquid outlet channel 301 that communicates with the stirring cup 2. The liquid outlet channel 301 has a liquid outlet that can be directly drunk by the user. mouth 302, you can drink with your mouth without removing the cup top seat, and the liquid outlet channel 301 is provided with a sealing device for sealing the liquid outlet channel 301 when the vacuum device 31 is vacuumed, so as to ensure that the device is sealing effect. In the vacuum-pumping mixer of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com