Special carving device for full-automatic ceramic surface machining

A ceramic surface, fully automatic technology, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of long processing time, large engraving error rate, high labor intensity, etc., achieve high processing efficiency, fast processing speed, and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

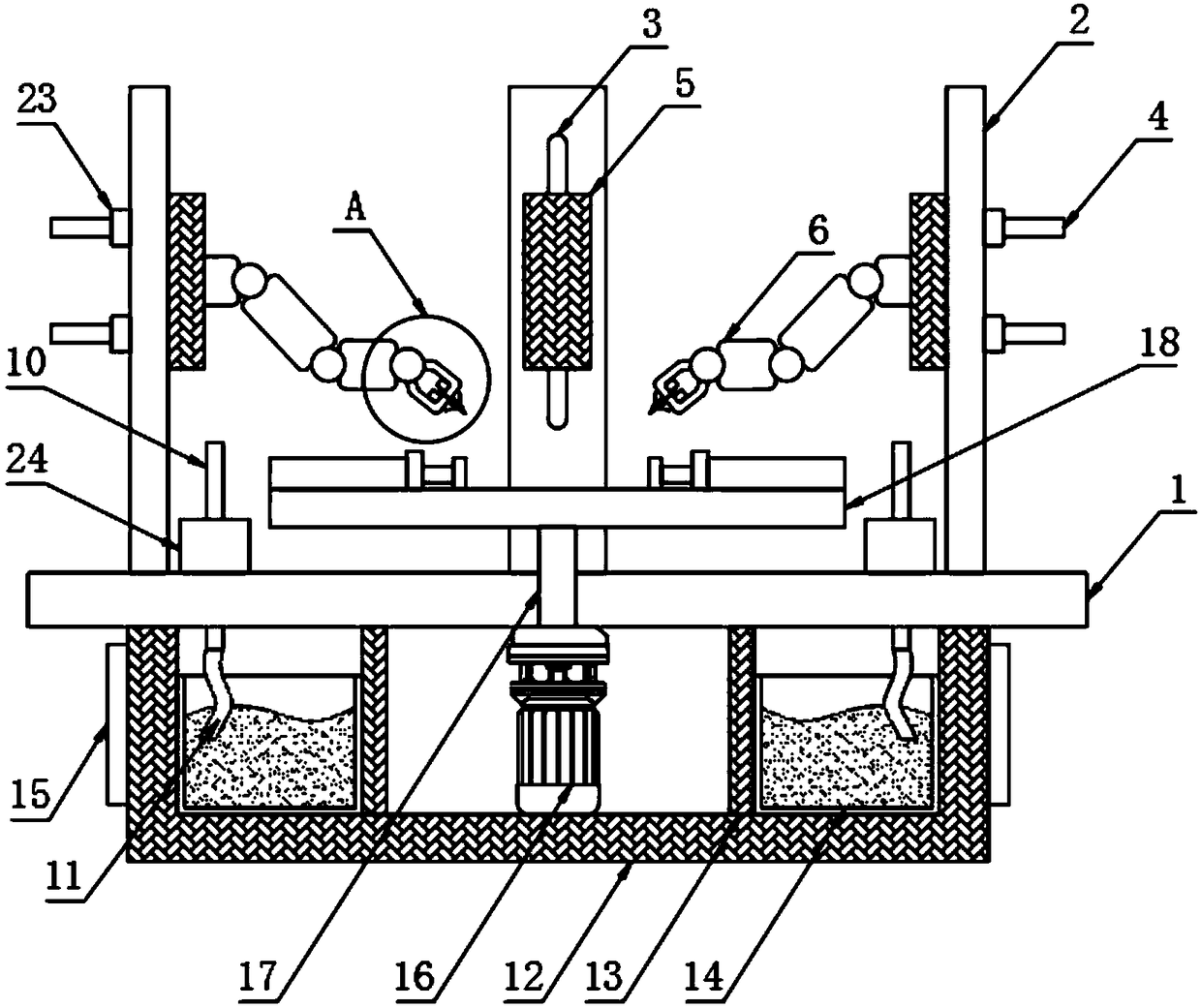

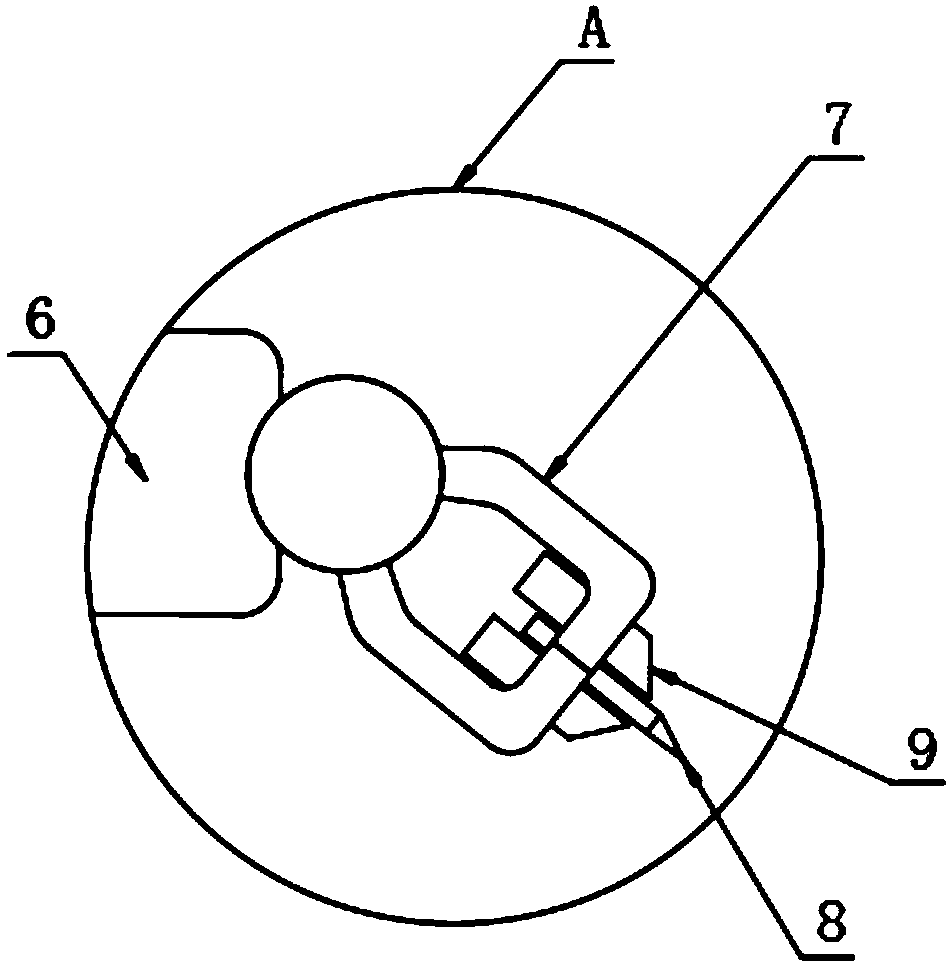

[0023] The present invention provides such Figure 1-3 A special engraving device for full-automatic ceramic surface processing as shown includes a workbench 1, a plurality of mounting plates 2 are fixed on the top of the workbench 1, and a mechanical arm base 5 is provided on the front side of the mounting plate 2, so that One side of the mechanical arm base 5 is fixed with a mechanical arm 6, the end of the mechanical arm 6 is provided with an electric clamp 7, and the electric clamp 7 is provided with a dust discharge pipeline 9, and the dust discharge pipeline 9 is connected with the electric clamp. 7 is fixedly connected, the electric clamp 7 is clamped with a carving knife 8, and the carving knife 8 is arranged between the dust discharge pipes 9, and the workbench 1 is penetrated with a delivery hard pipe 10, and the delivery hard pipe 10 is provided with a blower 24, the bottom end of the delivery hard pipe 10 is provided with a first hose 11, the bottom of the workbenc...

Embodiment 2

[0026] Further, in the above-mentioned embodiment 1, the mounting plate 2 is provided with a chute 3, and the other side of the mechanical arm base 5 is fixed with a screw 4, and the screw 4 is arranged inside the chute 3, so that A fastening nut 23 is threadedly connected to the outside of the screw rod 4, so as to adjust the height of the mechanical arm base 5.

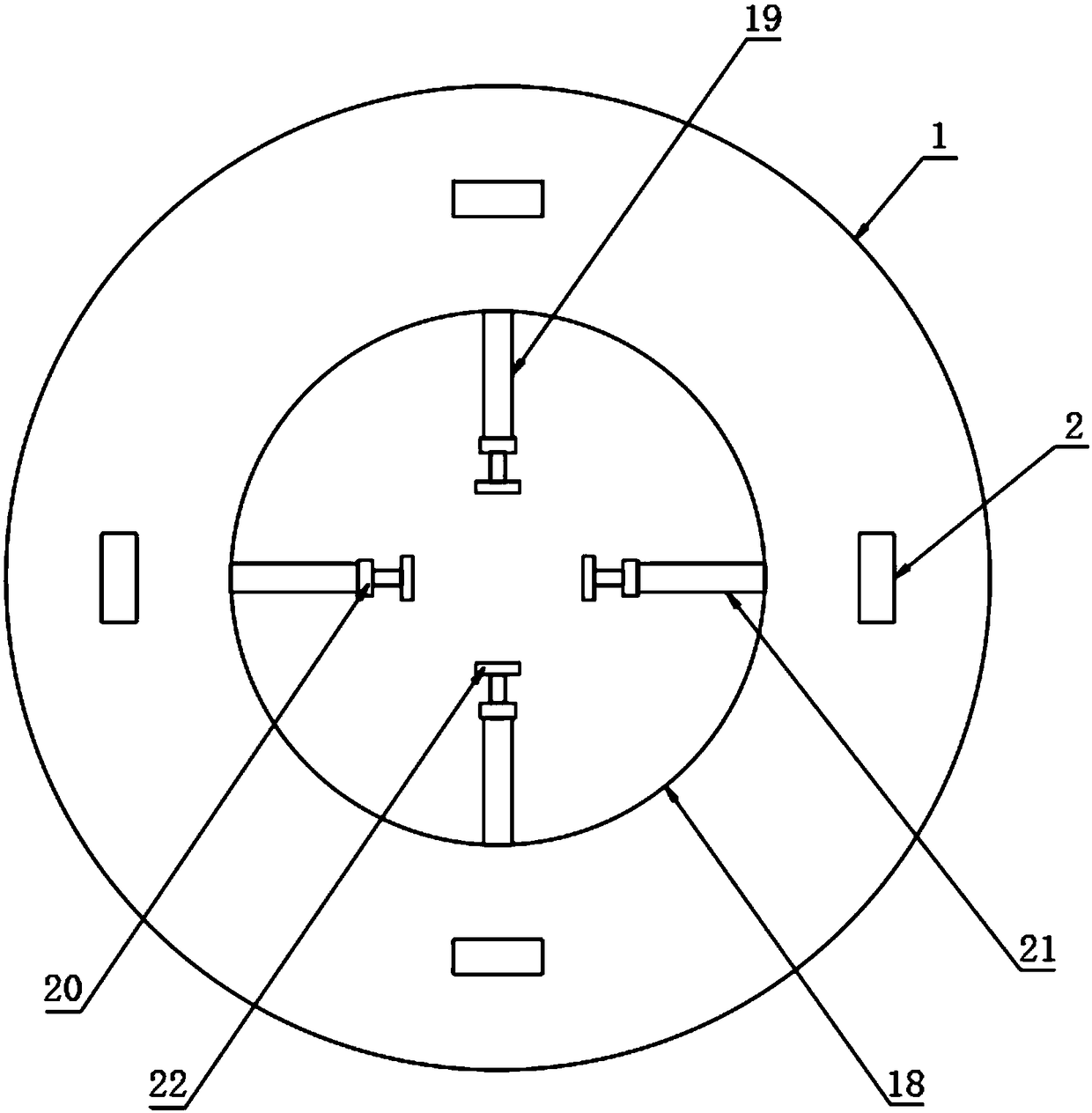

[0027] The carrying base 12 is provided with a motor 16 inside, the motor 16 is arranged inside the annular sealing plate 13, and the top of the motor 16 is provided with a rotating rod 17, and the rotating rod 17 runs through the bottom of the workbench 1 and extends to the workbench 1 At the top, a rotating table 18 is fixed on the top of the rotating rod 17 , and a limit mechanism 19 is fixed on the top of the rotating table 18 .

[0028] The limit mechanism 19 includes a limit installation plate 20, which is fixed on the top of the rotary table 18, the limit installation plate 20 is fixedly provided with a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com