Marble building material cutting and grinding integrated equipment with dustproof function

A technology for cutting and polishing marble, applied in stone processing equipment, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of low processing efficiency, time-consuming and labor-intensive, and affect the health of staff, so as to improve processing efficiency and structure Reasonable, the effect of improving the practical range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

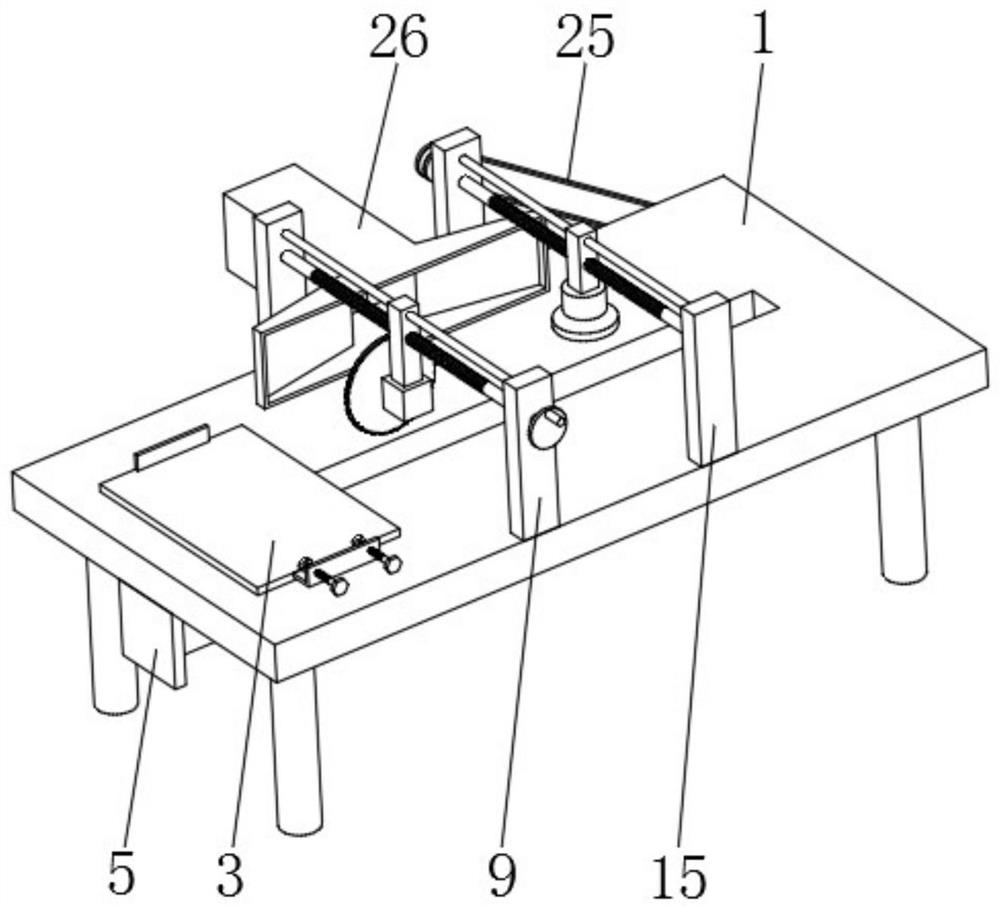

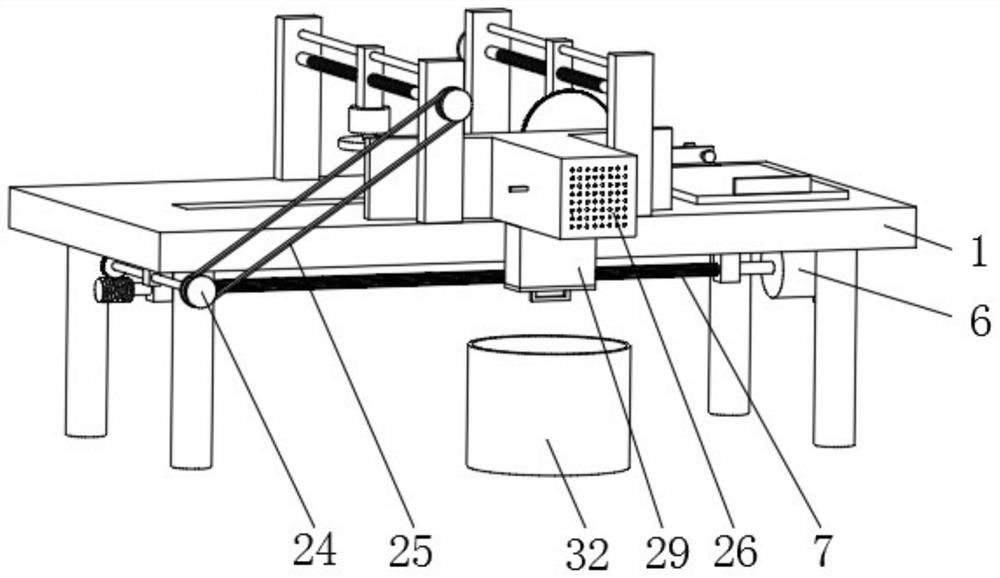

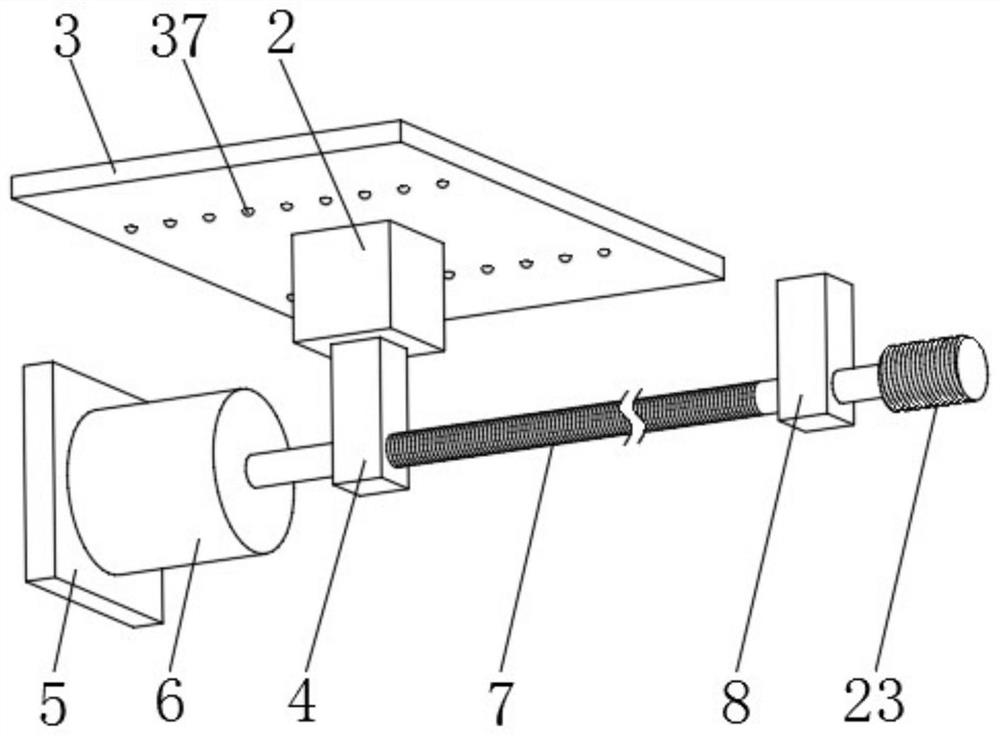

[0041] Example: Reference Figure 1-9 The shown marble building material cutting and polishing integrated equipment with dustproof function includes a processing table 1, on which a cutting and polishing part, a dust collection part and a conveying assembly are installed, and the conveying assembly includes a chute set on the top of the processing table 1, Slider 2 is slidably installed in the chute, the top of slider 2 is fixedly installed with placing plate 3, the bottom of slider 2 is fixedly installed with connection block 4, and the bottom of processing table 1 is fixedly installed with motor plate 5 and boss 8, One side of the motor plate 5 is fixedly installed with a servo motor 6, and the output end of the servo motor 6 is driven and connected with a moving screw 7, and one end of the moving screw 7 is threaded through the connection block 4 and rotated through the boss 8 in sequence and passes through the driving connection mechanism. Connected with the cutting and gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com