Patents

Literature

32results about How to "Keep the air clean" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

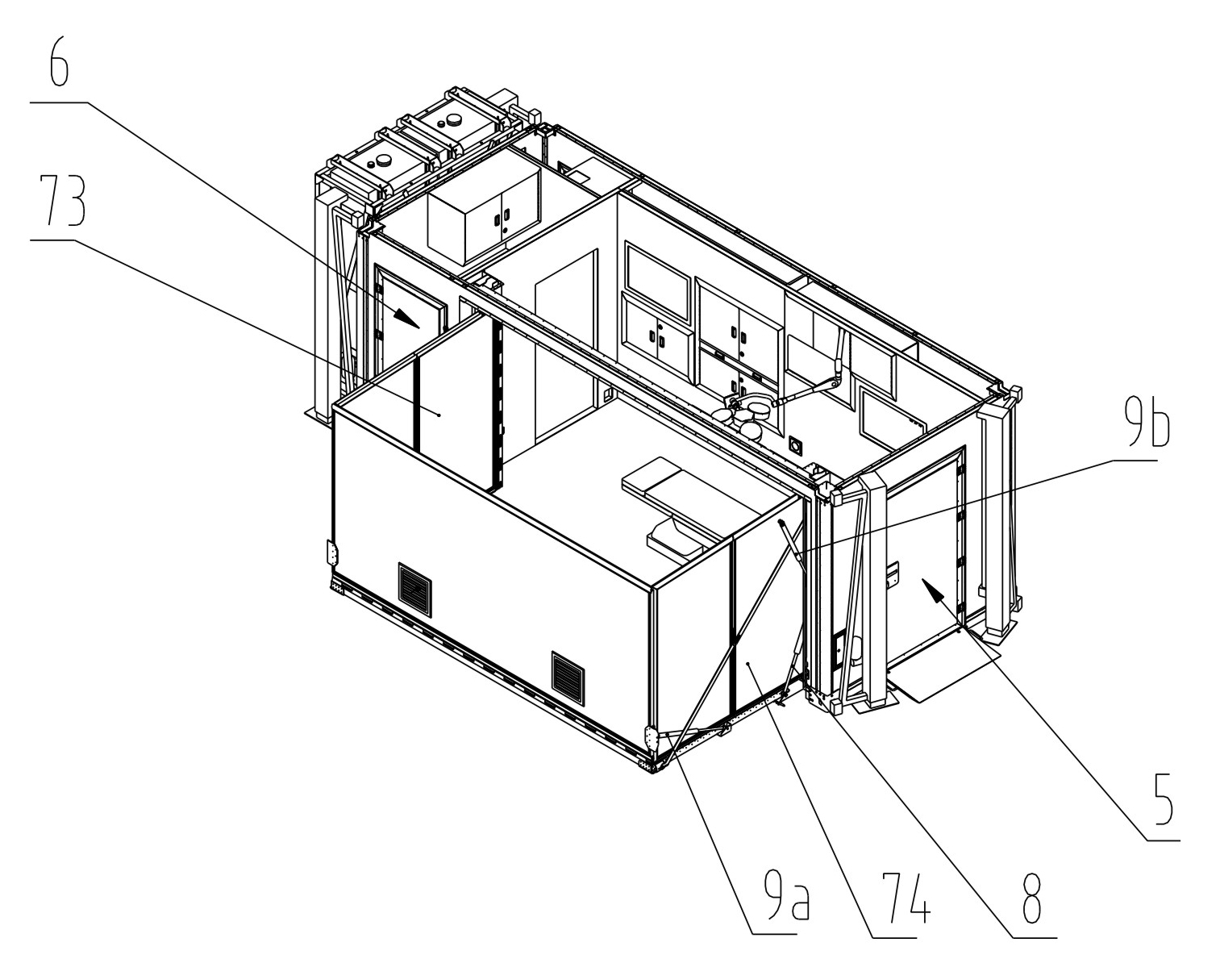

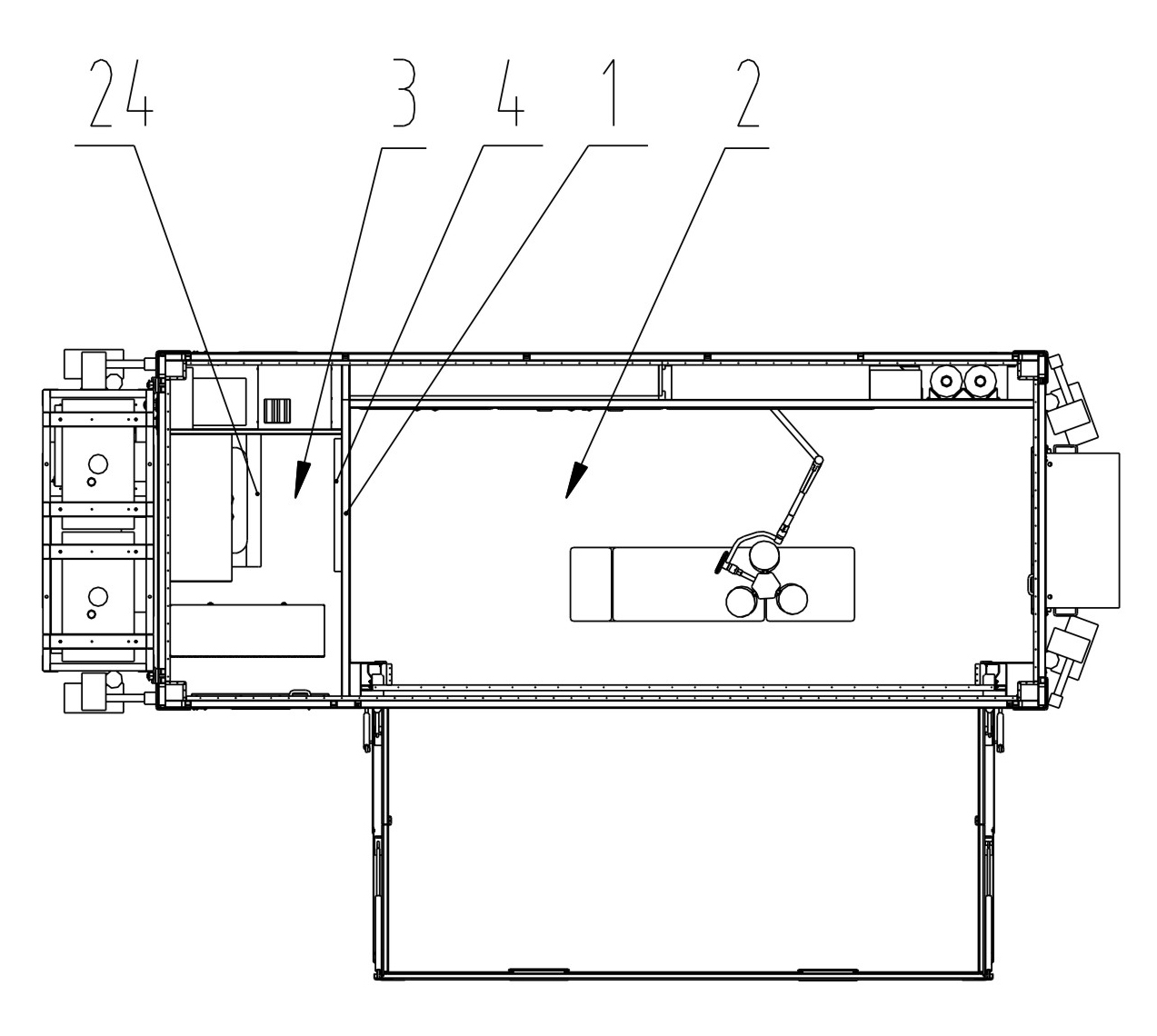

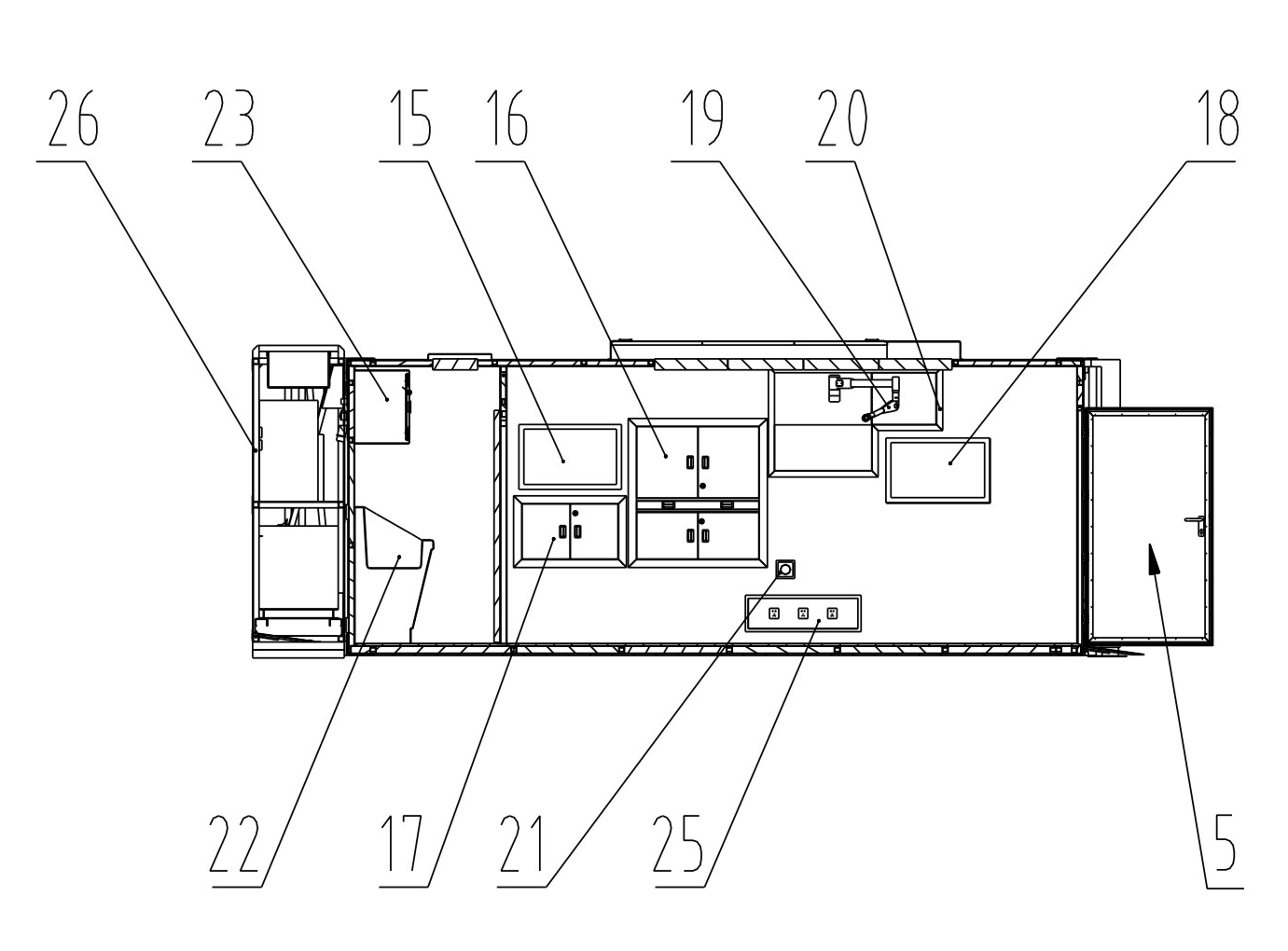

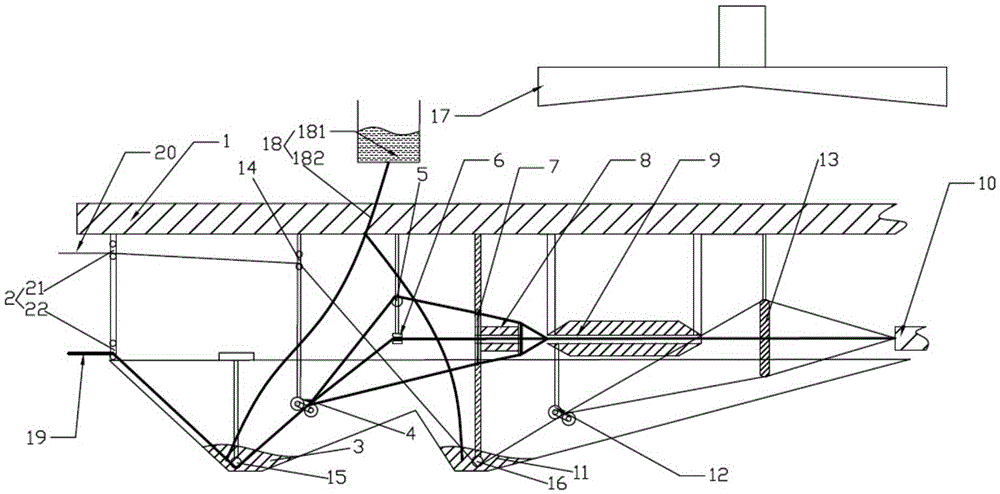

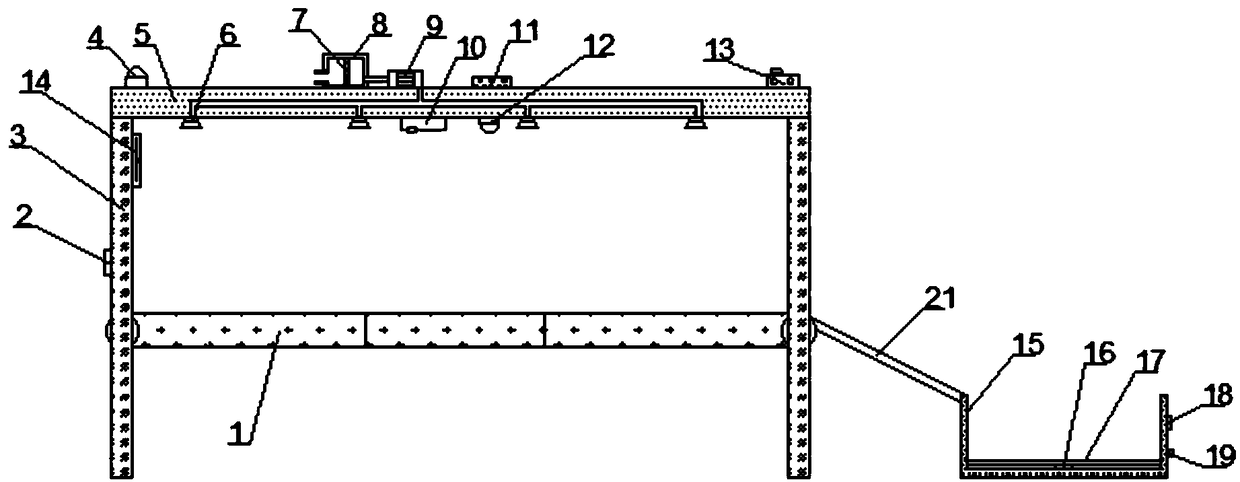

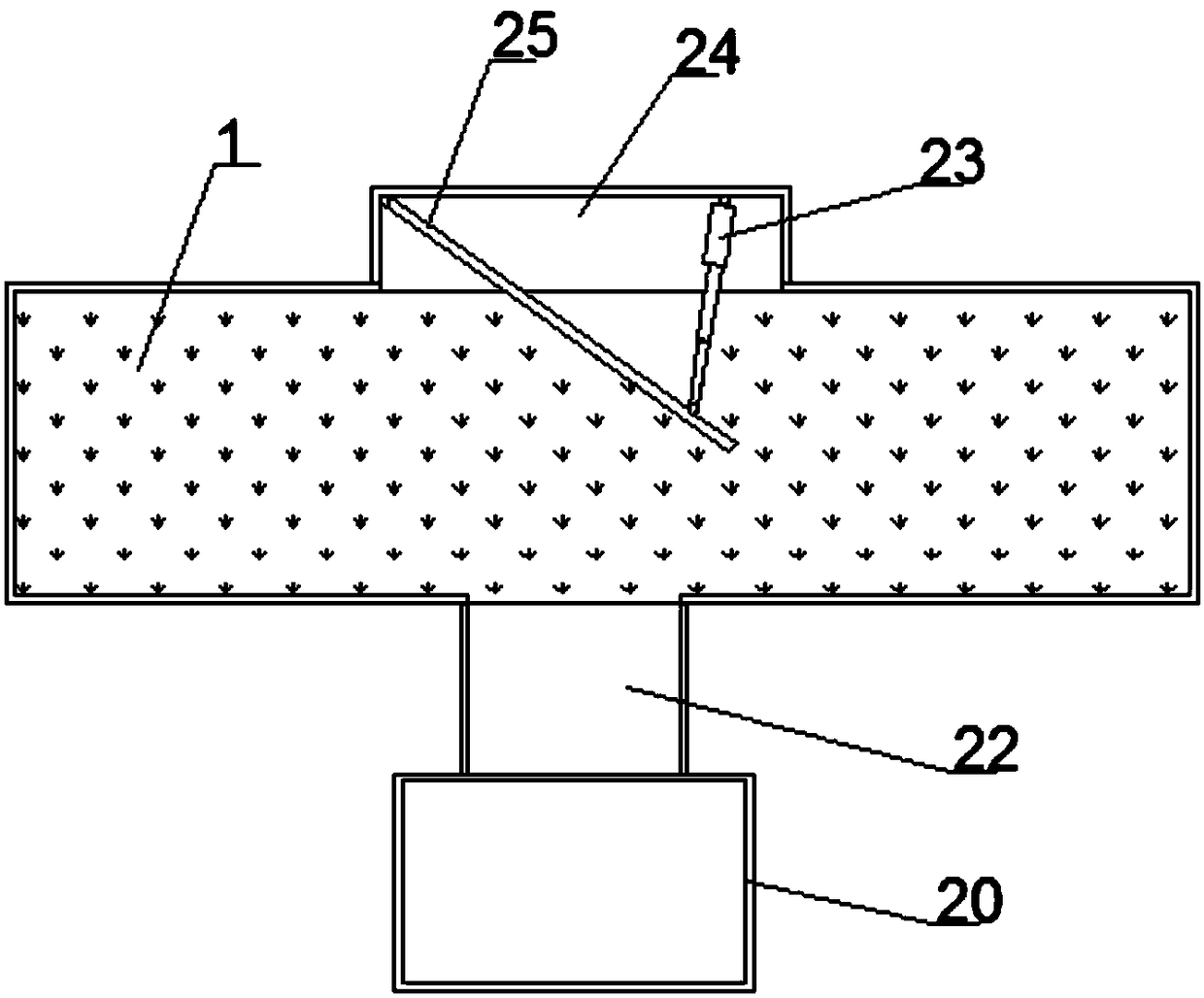

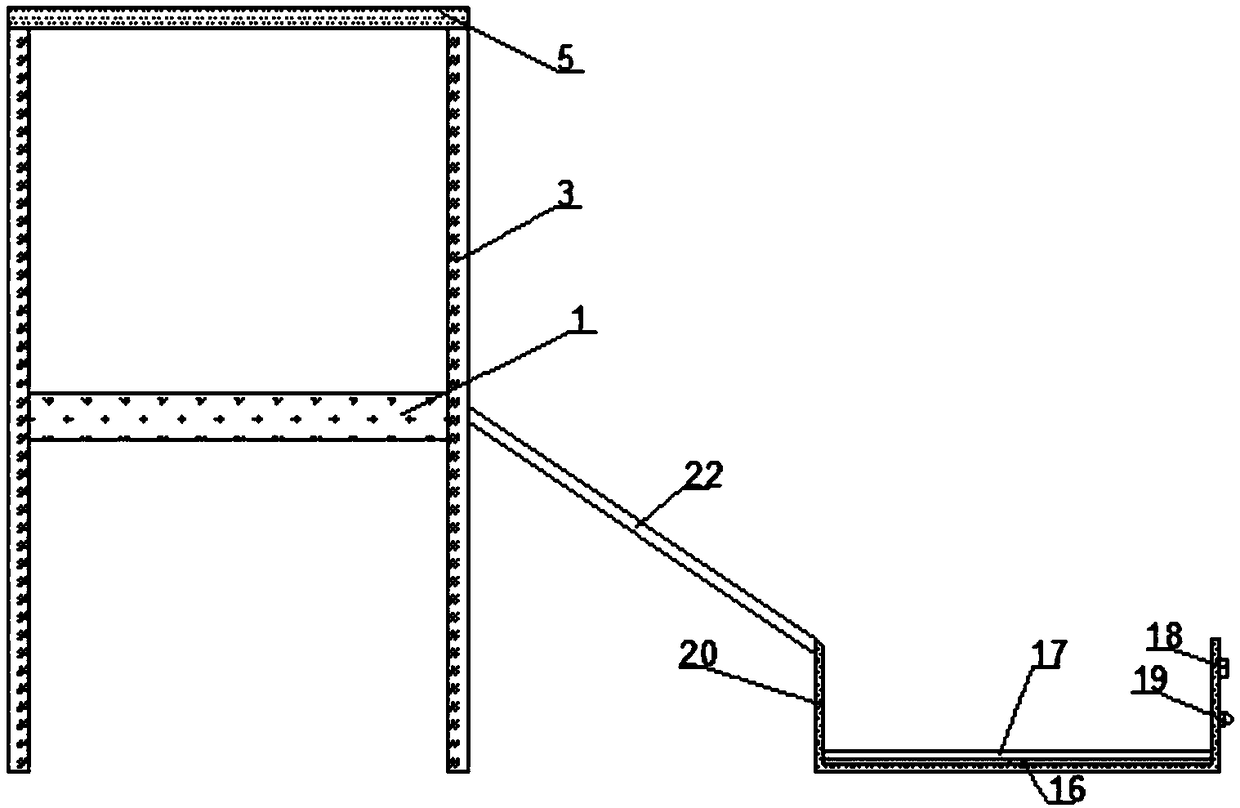

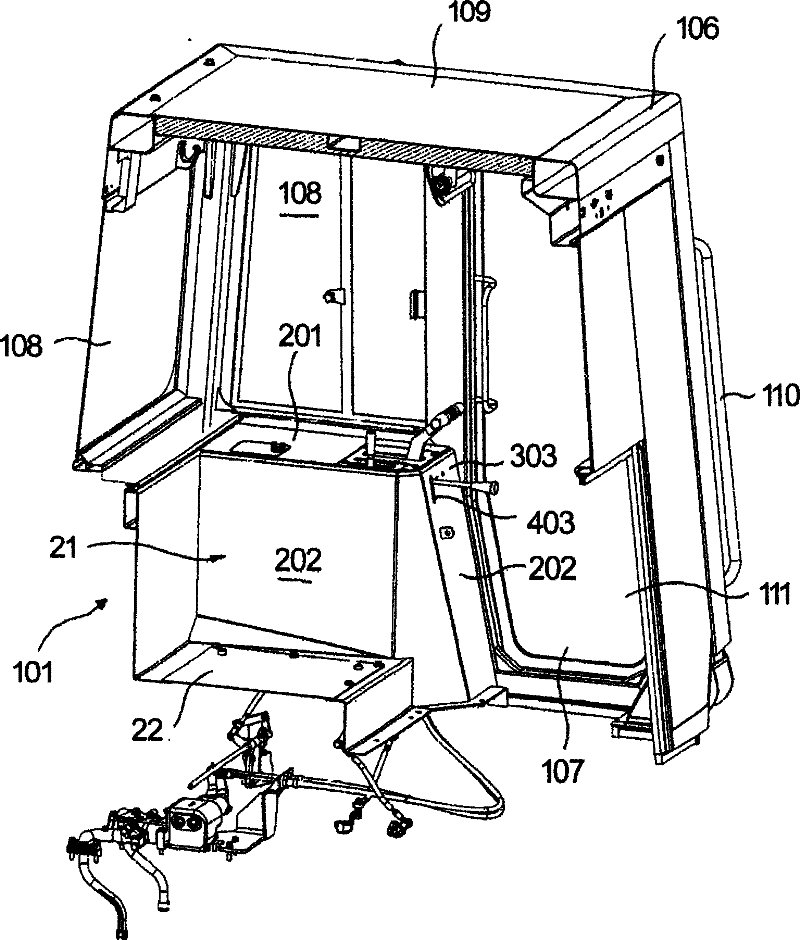

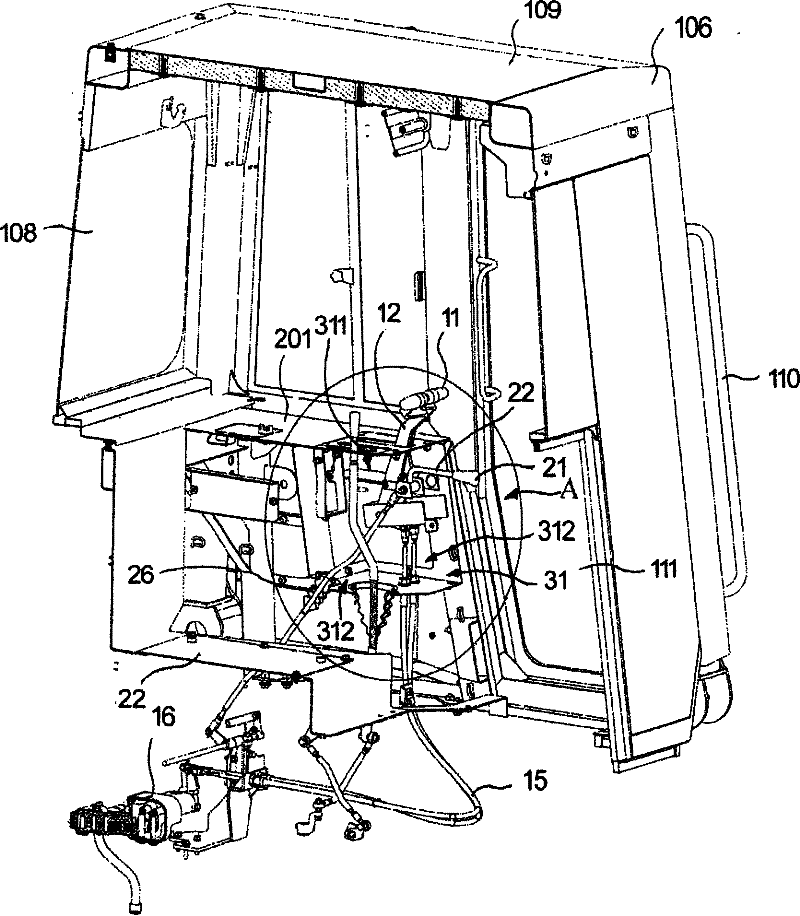

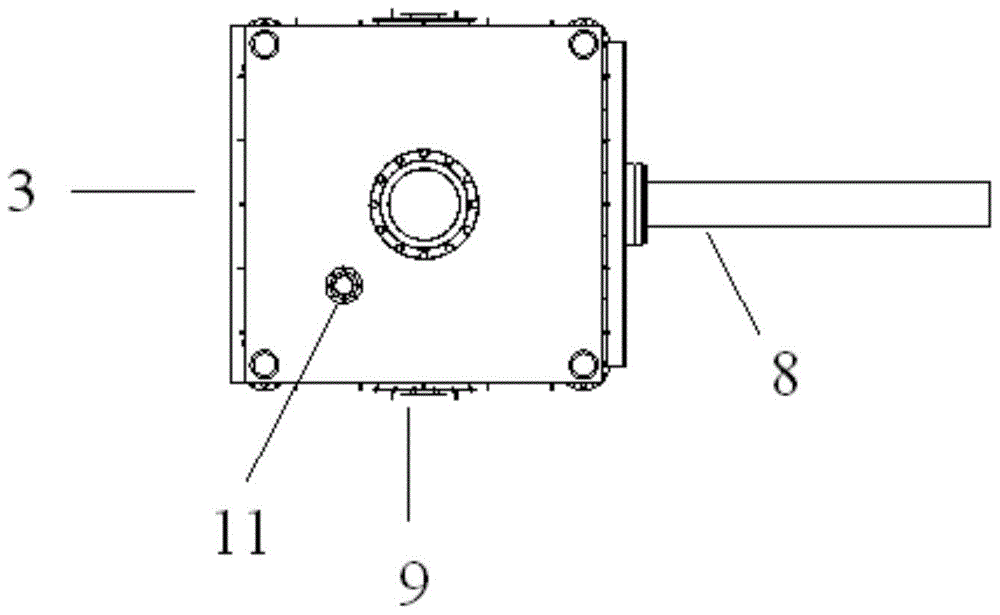

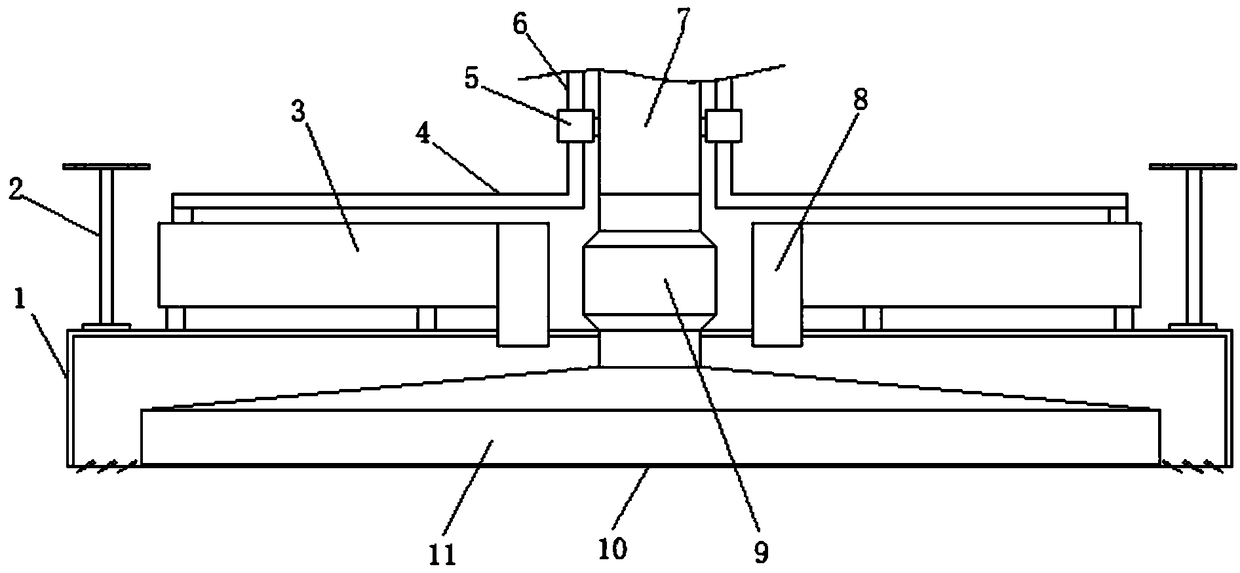

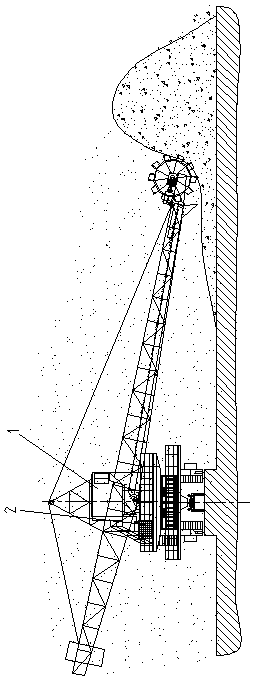

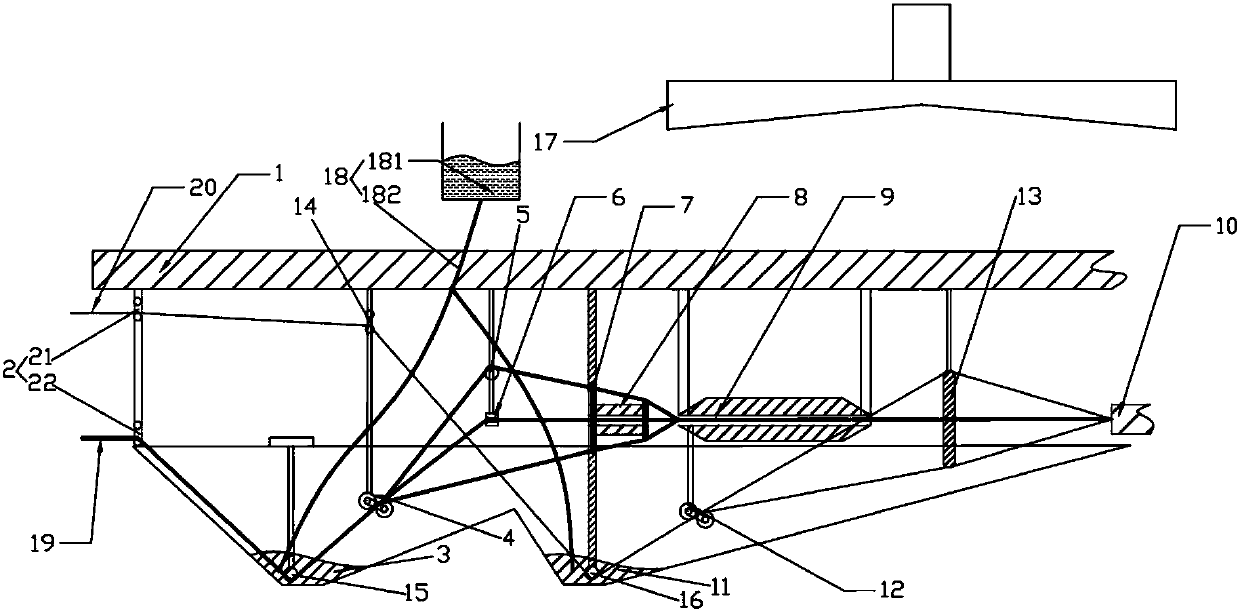

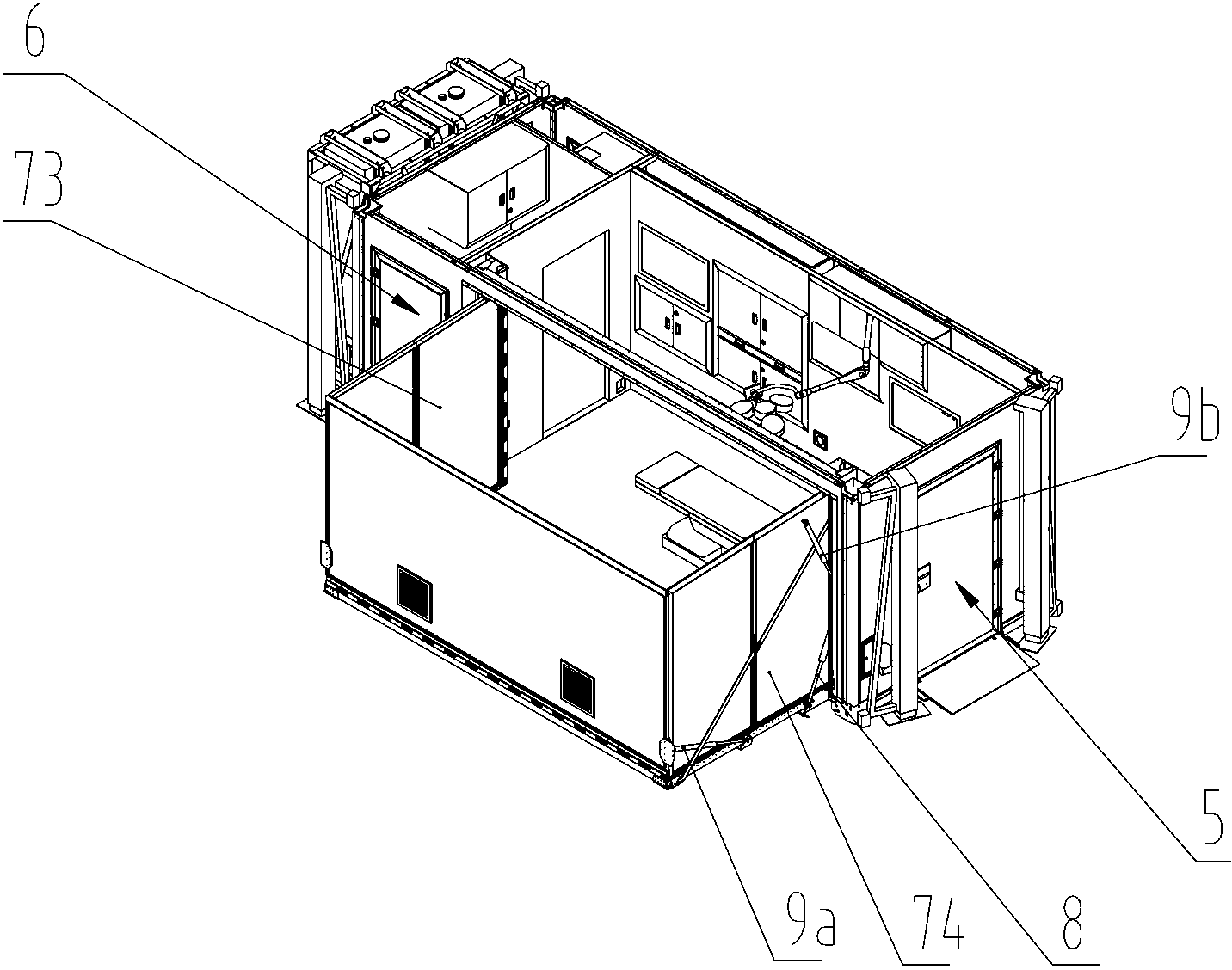

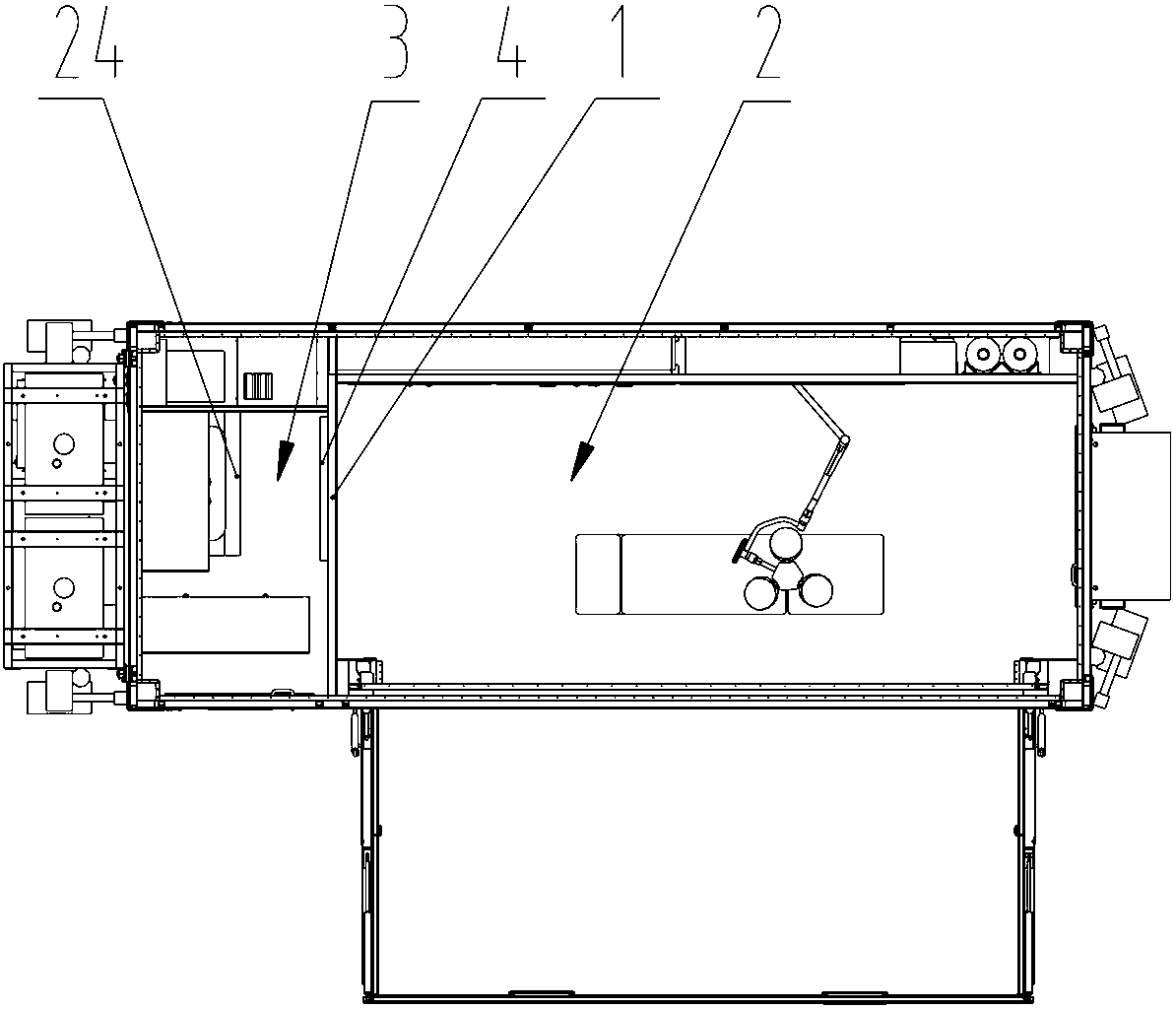

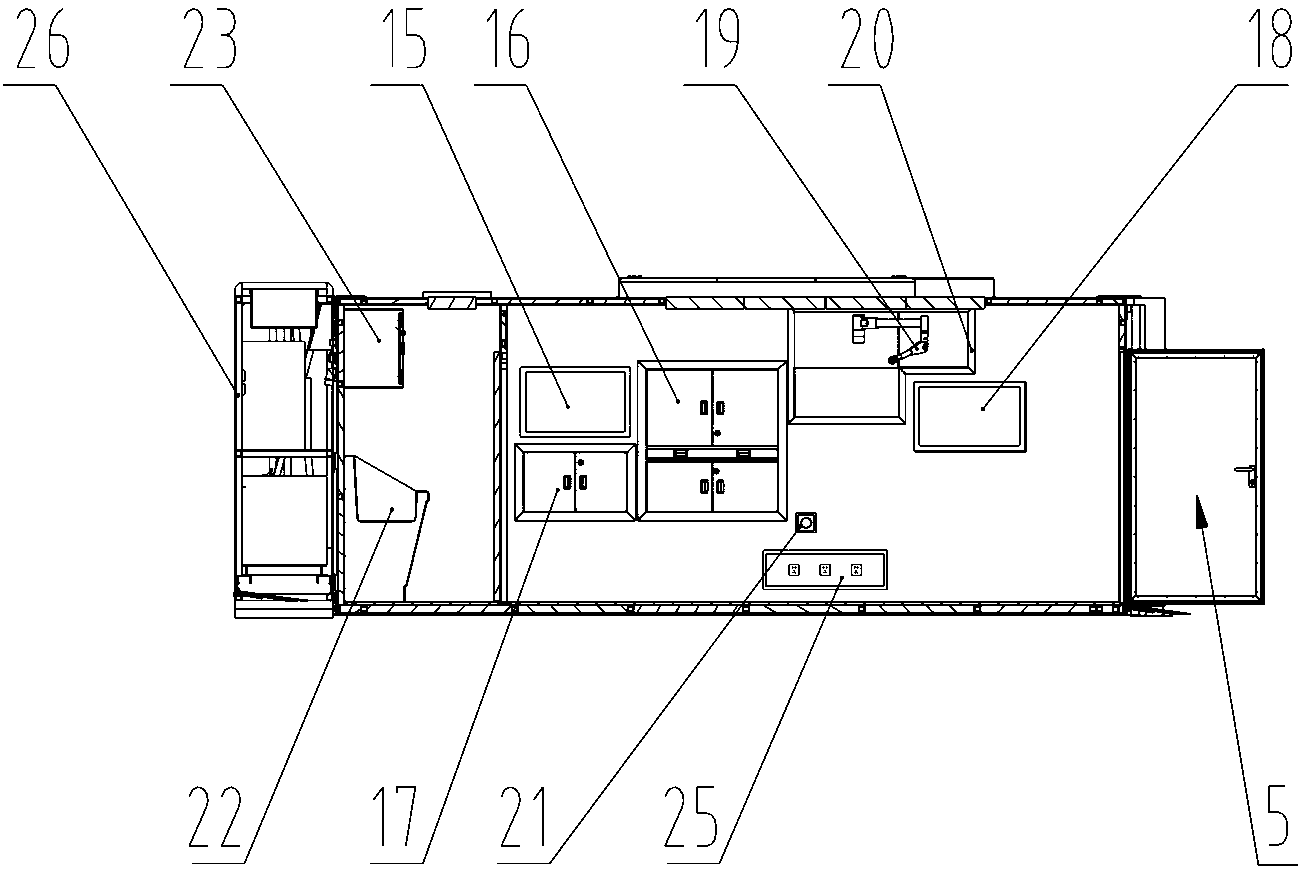

Clean operation shelter

ActiveCN102409873AEasy to carry outBig spaceLighting and heating apparatusHospitalsConstant forceAir cleaning

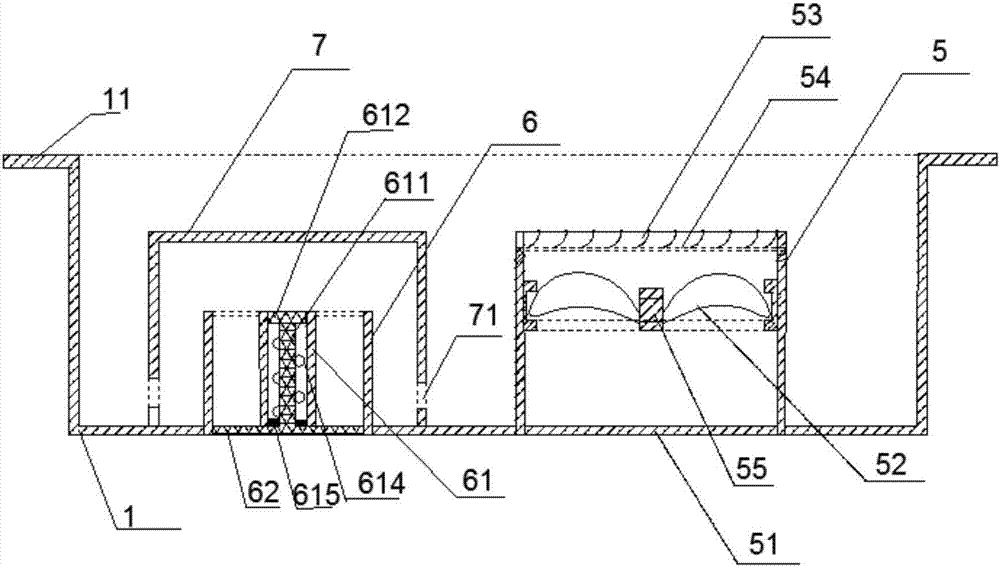

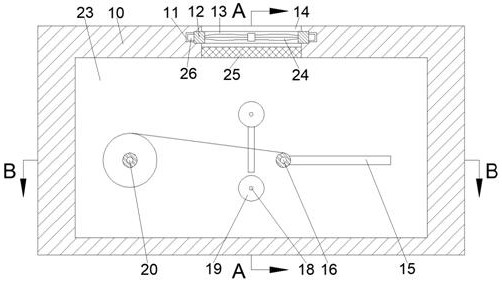

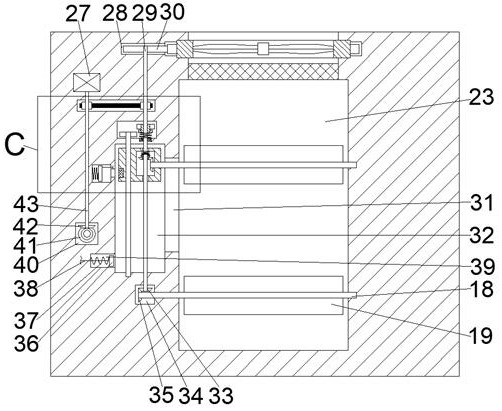

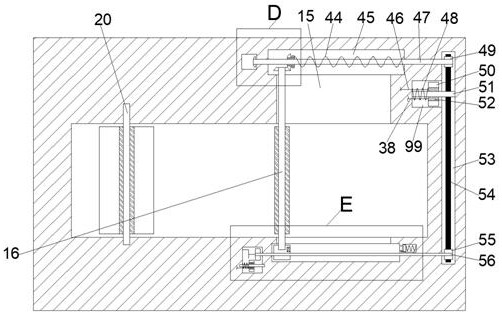

The invention provides a clean operation shelter comprising an operation shelter and a preparation shelter which are separated by a cross wall; an automatic sensing door is arranged on the cross wall; the operation shelter and the preparation shelter are respectively provided with a shelter door; air cleaning systems are respectively arranged in the operation shelter and the preparation shelter; one side surface of the operation shelter is provided with a foldable expansion shelter; the expansion shelter comprises a bottom plate, a side plate, a front end plate, a rear end plate and a top plate; the bottom plate is hinged at the bottom of the side surface of the operation shelter; the top plate is hinged on the top of the side surface of the operation shelter; the side plate is hinged with the bottom plate; the front end plate and the rear end plate are respectively hinged on two vertical sides of the side surface of the operation shelter; two oil cylinders are arranged in the operation shelter; piston rods of the two oil cylinders are respectively connected to the front edge and the rear edge of the bottom plate; a retractable lower constant force support device is connected between the side plate and the bottom plate; and a retractable lower constant force support device is connected between the top plate and the side surface of the operation shelter. The clean operation shelter not only can keep the air in the operation shelter clean but also can expand the space of the operation shelter.

Owner:CHONGQING ENDURANCE IND +2

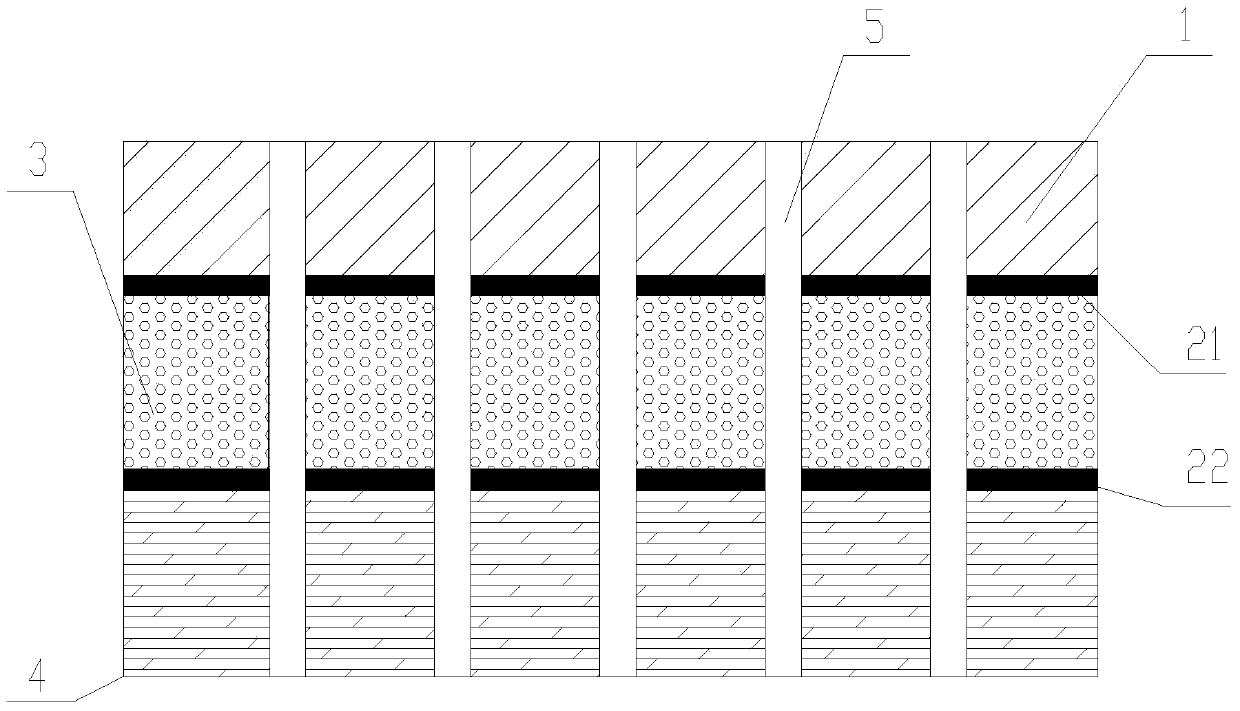

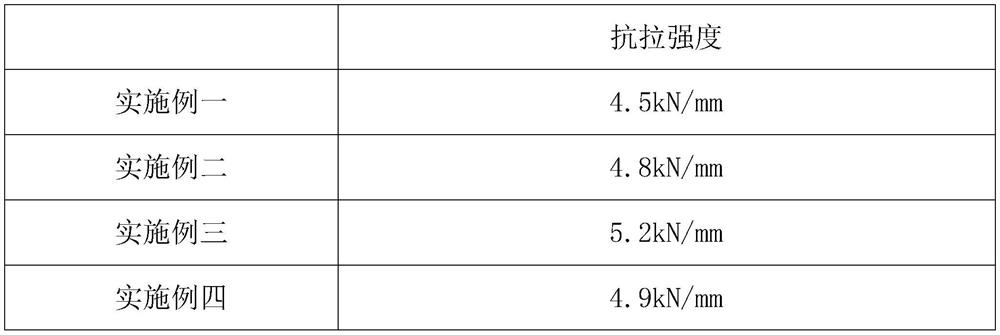

Gel-anion-bamboo charcoal composite latex sponge and manufacturing method thereof

The invention provides a gel-anion-bamboo charcoal composite latex sponge and a manufacturing method thereof, and specifically relates to a gel-anion-bamboo charcoal composite latex sponge which is soft to touch, highly elastic, healthy and environment-friendly, and a manufacturing method thereof. The gel-anion-bamboo charcoal composite latex sponge comprises a gel sponge layer, an anion sponge layer and a bamboo charcoal sponge layer; the gel sponge layer is connected with the anion sponge layer by use of a first natural cross-linking agent layer; the anion sponge layer is connected with the bamboo charcoal sponge layer by use of a second natural cross-linking agent layer; the gel sponge layer comprises the following components in parts by weight: 100 parts of natural latex, 3-8 parts of gel, 1-9 parts of sulfur, 1-6 parts of zinc oxide, 1-5 parts of accelerant, 0.5-2 parts of sodium fluosilicate and 0.1-2 parts of potassium castorate; the anion sponge layer comprises the following components in parts by weight: 100 parts of natural latex, 2-5 parts of anion powder, 1-9 parts of sulfur, 1-6 parts of zinc oxide, 1-5 parts of accelerant, 0.5-2 parts of sodium fluosilicate and 0.1-2 parts of potassium castorate. The gel-anion-bamboo charcoal composite latex sponge has no irritation to skin and has a powerful sterilization effect.

Owner:江苏金世缘乳胶制品股份有限公司

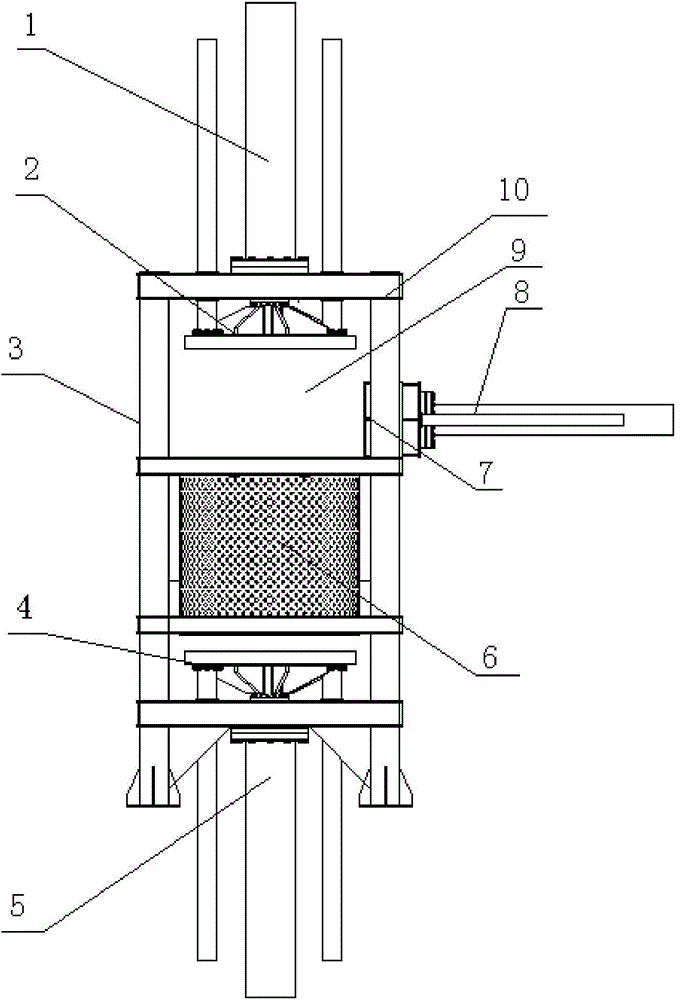

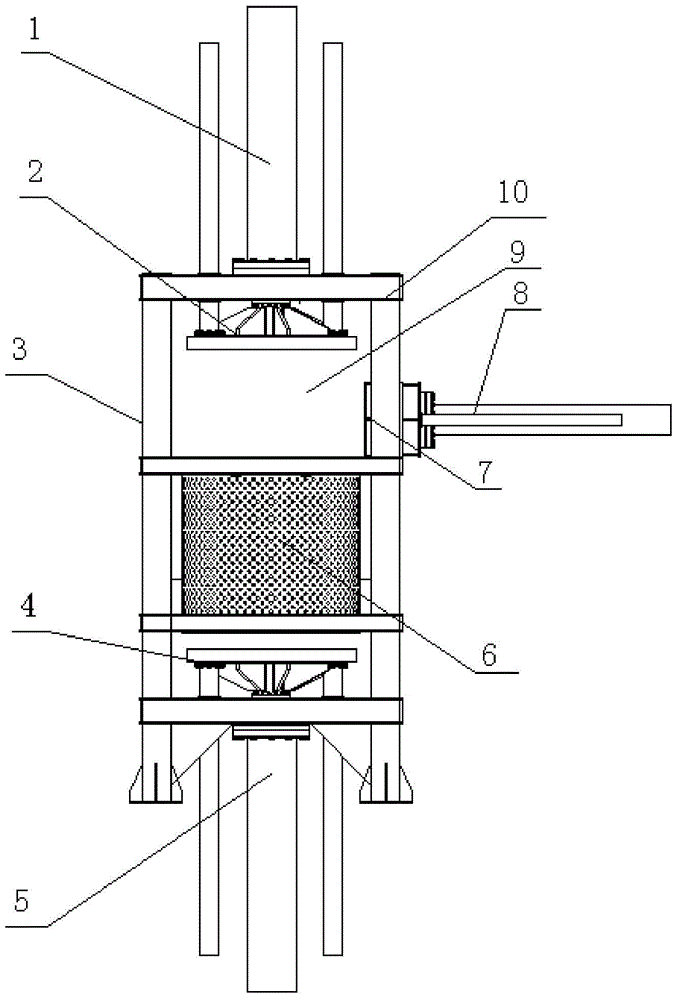

Rubbish dehydration solid-liquid separation device

The invention discloses a rubbish dehydration solid-liquid separation device. The rubbish dehydration solid-liquid separation device comprises a closed solid-liquid separation cylinder body, a downward-moving hydraulic system with a lower push plate, a discharging hydraulic system with a discharging push plate and an upward-moving hydraulic system with an upper push plate. A feeding opening and a discharging opening are formed in the upper portion of the solid-liquid separation cylinder body. The lower push plate of the downward-moving hydraulic system is arranged on the top of the solid-liquid separation cylinder body and can move up and down along an inner cavity of the solid-liquid separation cylinder body. The upper push plate of the upward-moving hydraulic system is arranged at the bottom of the solid-liquid separation cylinder body and can move up and down along the inner cavity of the solid-liquid separation cylinder body. The discharging push plate of the discharging hydraulic system is arranged at the position, corresponding to the discharging opening, of the solid-liquid separation cylinder body, and can make transverse movement along the inner cavity of the solid-liquid separation cylinder body. According to the rubbish dehydration solid-liquid separation device, a double-direction vertical hydraulic squeezing mode is adopted, powerful squeezing can be provided, the problems of winding and hard object sticking in material dehydration can be solved, the adaptability to materials is high, the effects of rubbish reduction and volume reduction are obvious, the automation degree is high, and sealed deodorization can be achieved.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

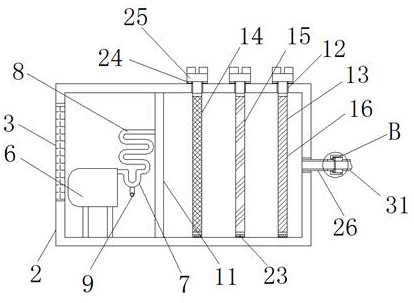

Shoe cabinet with telescopic bench

InactiveCN107495656AEasy to change shoesAchieve sterilizationWardrobesFurniture partsAir exchangeMechanical engineering

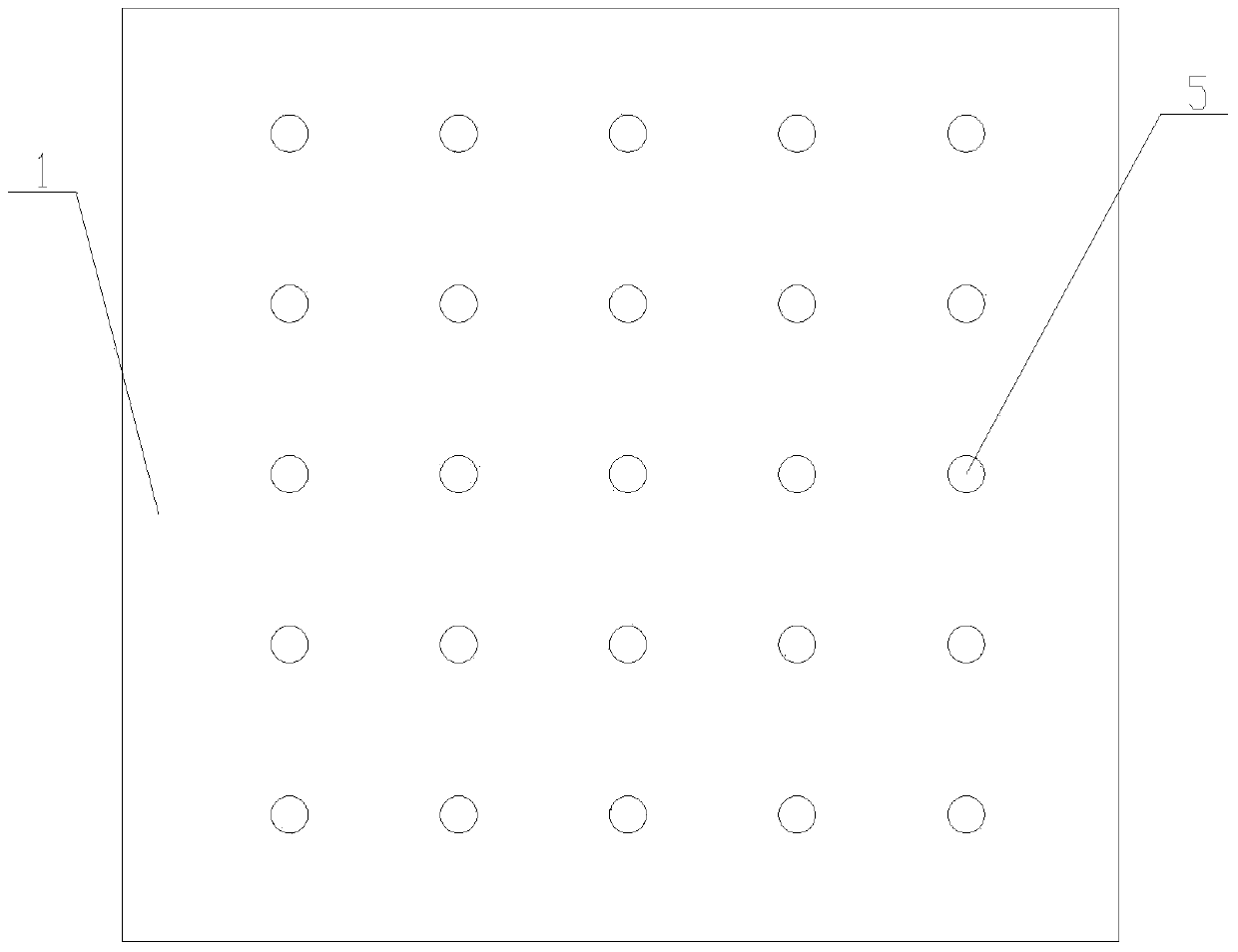

The invention discloses a shoe cabinet with a telescopic bench. The shoe cabinet comprises a shoe cabinet body, wherein one side of the shoe cabinet body is opened; a cabinet door is arranged at the opening; a plurality of holding plates are arranged from top to bottom in sequence inside the shoe cabinet body; a multifunctional box body is arranged below the shoe cabinet body; a box tank of which one end is opened is arranged inside the multifunctional box body; the box tank is internally connected with a bench box; a box door is hinged with the opening; the bench box can be pulled out and withdrawn into the box tank along the opening; a sterilization air exchange tube is arranged inside the shoe cabinet body; the lower end of the sterilization air exchange tube extends into the top of the multifunctional box body and extends out from a side surface of the multifunctional box body; sterilization air exchange holes are distributed in the wall of the sterilization air exchange tube. According to the shoe cabinet disclosed by the invention, due to adoption of the telescopic bench, people can sit down to change shoes at the shoe cabinet at an entryway, and then shoes can be relatively conveniently changed; due to adoption of the sterilization air exchange tube, the shoe cabinet can be sterilized, the shoe cabinet can be communicated with the outside to exchange air inside the shoe cabinet, and thus the air inside the shoe cabinet is kept clean.

Owner:成都市弘盛科技有限公司

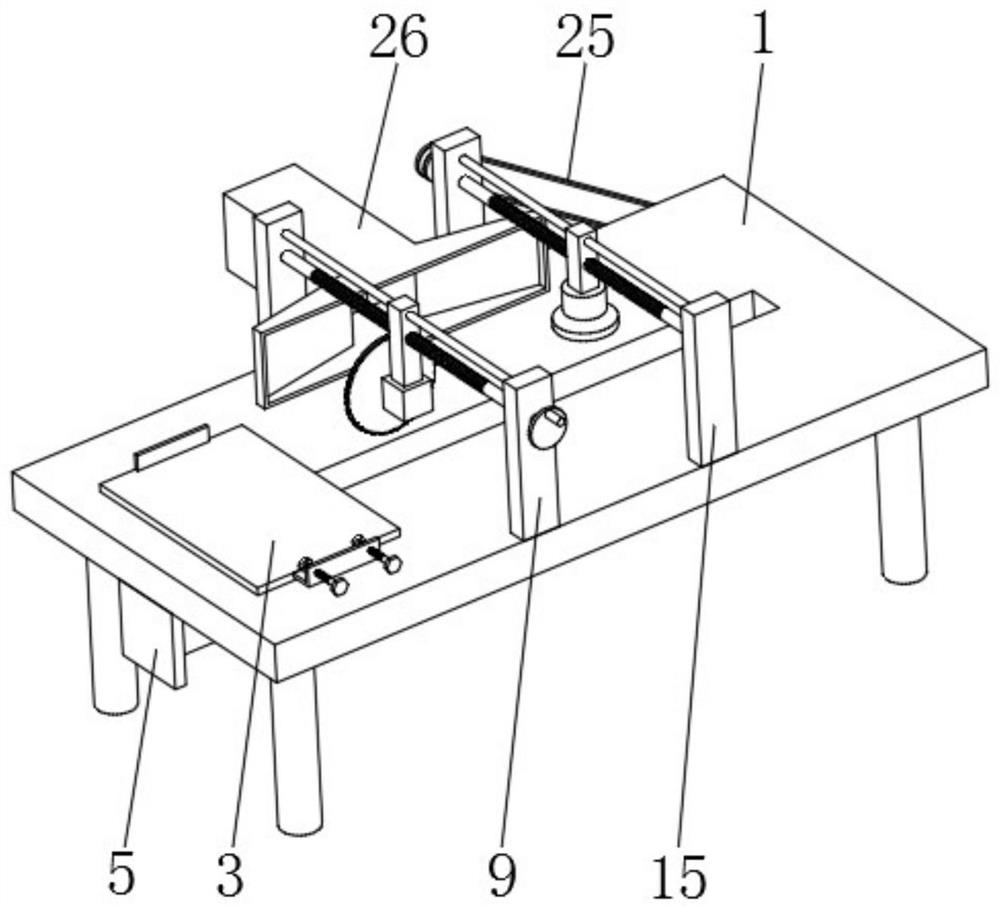

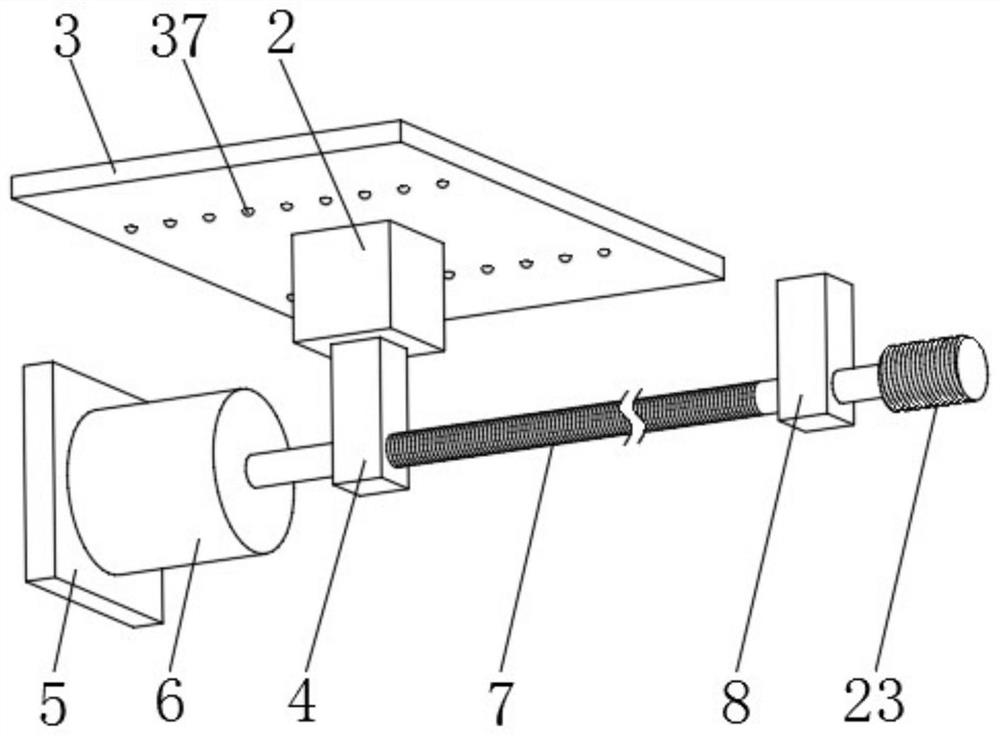

Marble building material cutting and grinding integrated equipment with dustproof function

InactiveCN113199638AReasonable structureImprove processing efficiencyGrinding carriagesDispersed particle filtrationArchitectural engineeringStructural engineering

The invention discloses marble building material cutting and grinding integrated equipment with a dustproof function, and relates to the field of marble building material machining equipment. The marble building material cutting and grinding integrated equipment comprises a machining table, wherein a cutting and grinding part, a dust collection part and a conveying assembly are installed on the machining table, and the conveying assembly comprises a sliding groove formed in the top of the machining table; and a sliding block is installed in the sliding groove in a sliding manner. According to the marble building material cutting and grinding device, when a servo motor is started, a placing plate can be driven to move, so that marble building materials are sequentially subjected to cutting treatment through a cutting machine and grinding treatment through a grinding machine, cutting and grinding of the marble building materials can be completed at a time, workers do not need to carry the marble building materials any more, time and labor are saved, and the machining efficiency is improved; and when a suction fan is started, dust generated by cutting and grinding can be sucked into a dust suction pipe, so that it is guaranteed that air in the field working environment is clean, and the situation that because the workers suck the dust for a long time, the health of workers is affected can be effectively avoided.

Owner:杭州勇冠网络科技有限公司

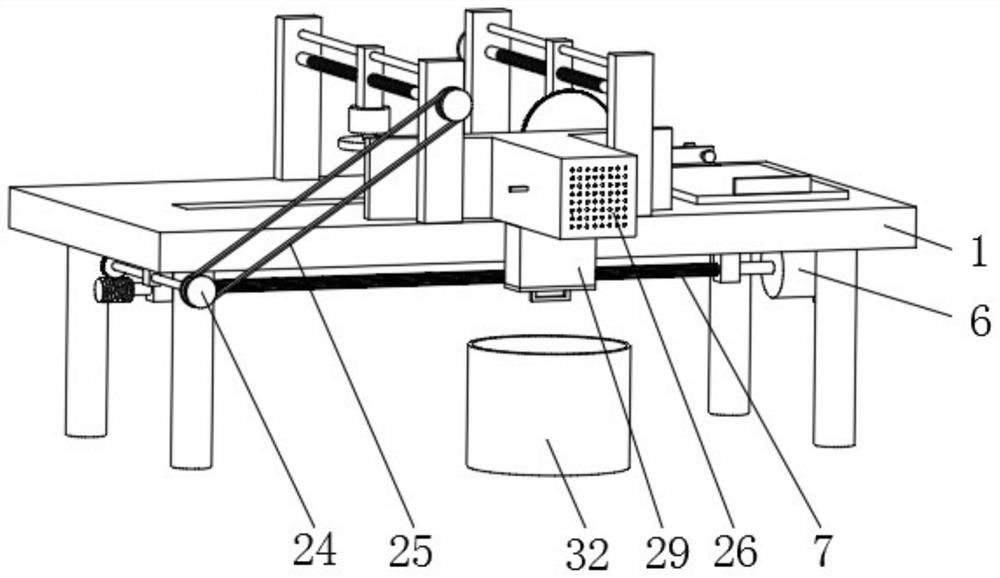

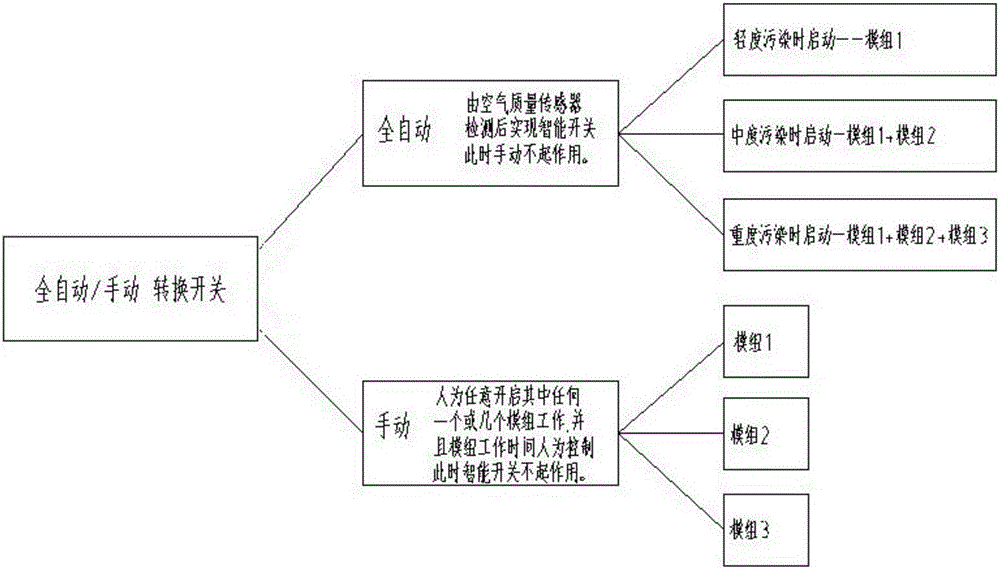

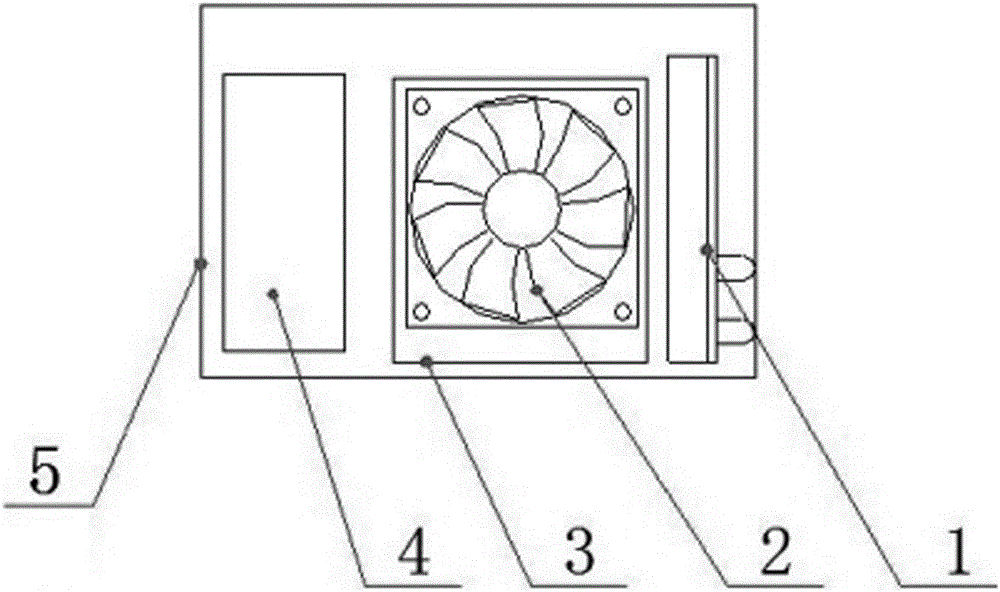

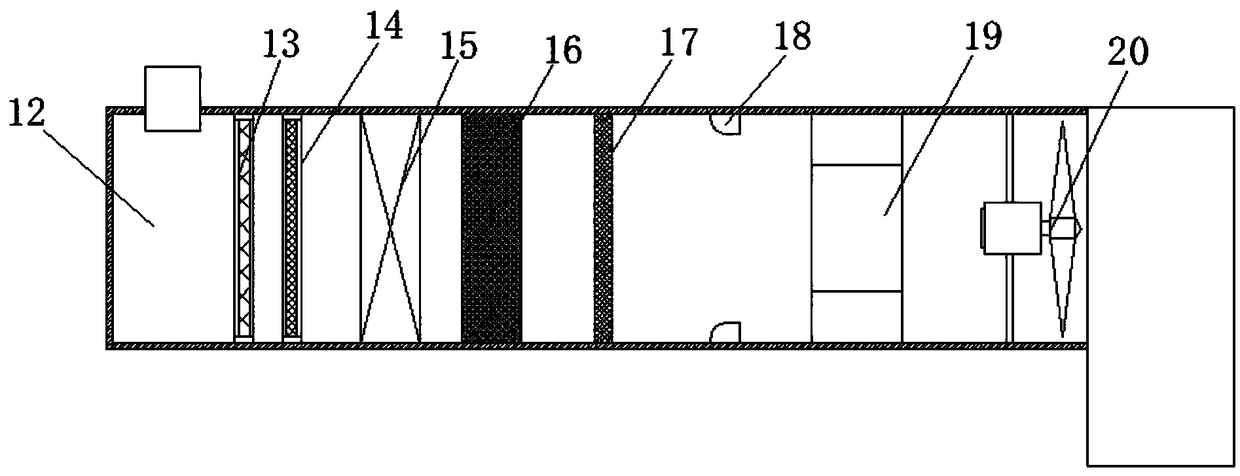

Air purifier with automatic smell and smoke removal and disinfection functions and air purifying method thereof

InactiveCN106016484AAchieve deodorizationAchieve purification effectMechanical apparatusSpace heating and ventilation safety systemsAir purifierAir pollution

The invention discloses an air purifier with automatic smell and smoke removal and disinfection functions. The air purifier comprises a shell with an internal accommodating space, and the shell is provided with a hole matched with an air in / out opening of an air pipeline. The air pipeline is arranged in the shell, and a fan and an ultraviolet lamp are mounted inside the air pipeline. The shell is further internally provided with a purifying module for achieving an air purifying function, an air quality sensor used for monitoring the air pollution degree and an intelligent full automatic / manual switch system board for switching working states of the air purifier. The intelligent full automatic / manual switch system board is electrically connected with the purifying module and the air quality sensor. The invention further discloses an air purifying method. In a full-automatic mode, the purifier is always in a standby state, automatic monitoring and purifying are achieved, the purpose of rapidly removing pollution is achieved, and pollution diffusion, deposition and aggravating are effectively avoided; and in a manual mode, any one technical module or several technical modules can be turned on according to pollution conditions or disinfection requirements, and the purifying time can be manually controlled.

Owner:万忠清

Device and method for clearing manure of large-scale rabbit farm

The invention belongs to the technical field of rabbit cultivation and relates to a device and method for clearing manure of a large-scale rabbit farm. The device for clearing manure of the large-scale rabbit farm comprises a manure furrow which is of a V-shaped cement structure and has a gradient of 45 degrees. A conveying belt is installed at the bottom of the manure furrow and connected with a motor. The motor is connected with a timing switch. The conveying belt starting time is controlled through well set time, and the conveying belt runs on time to be used for clearing the manure. According to the device and method for clearing manure of a large-scale rabbit farm, the genuine automatic manure clearing can be performed, the manure utilization rate can be improved, harmful gases such as rabbitry ammonia are reduced, manure entering sewage is reduced, and environmental pollution is reduced. The maintenance cost can be lowered, and the maintenance time is saved.

Owner:QINGDAO KANGDA RABBIT IND DEV +1

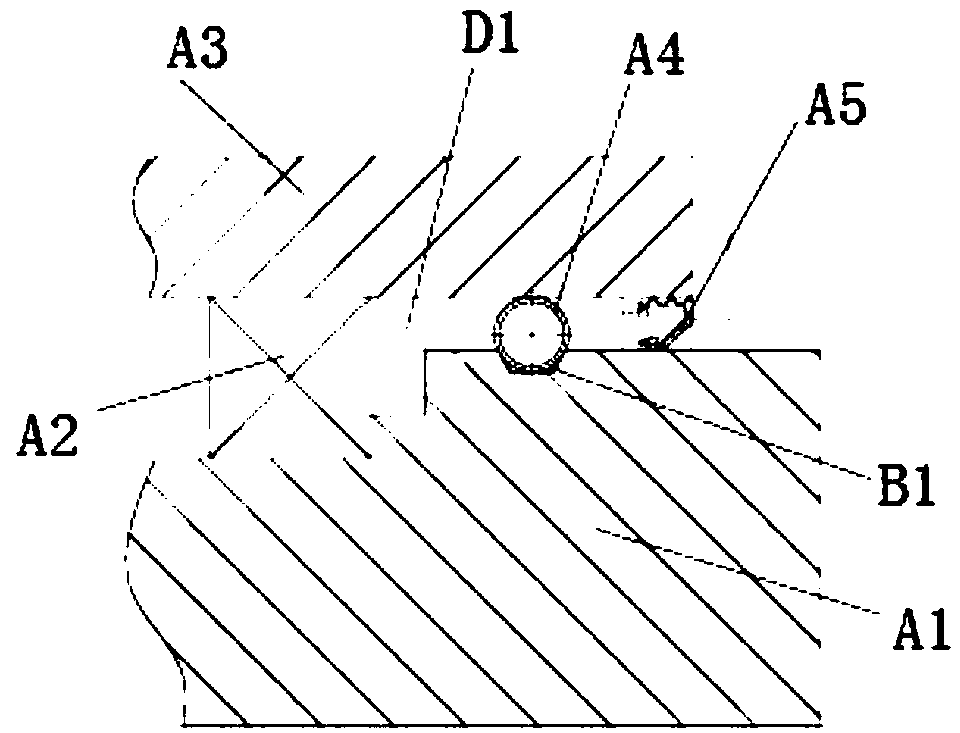

Winding type composite core pultrusion impregnation process for smart energy and special impregnation apparatus therefor

The invention discloses a winding type composite core pultrusion impregnation process for smart energy and a special impregnation apparatus therefor. The impregnation apparatus comprises a first yarn-splitting frame, a first impregnation groove, a first adhesive extruding roller, a second yarn-splitting frame, an adhesive scraper, a first yarn collector, a winder, a pre-curing die, a curing die, a second impregnation groove, a second adhesive extruding roller and a second yarn collector that are arranged on a tooling bracket, wherein an upper yarn-splitting device and a lower yarn-splitting device are arranged at the upper and lower ends of the first yarn-splitting frame respectively; the first adhesive extruding roller and the second adhesive extruding roller are arranged at the upper parts of the first impregnation groove and the second impregnation groove respectively; the second yarn-splitting frame and the adhesive scraper are arranged at the front part of the first yarn collector; the first yarn collector is arranged at the front part of the winder; and the winder is arranged at the front part of the pre-curing die. According to the winding type composite core pultrusion impregnation process and the impregnation apparatus, continuous winding can be realized through the winder so as to produce the winding type composite core; the composite core is under transverse protection, so that the cracking of the composite core is avoided, and the composite core is safer to use; and in addition, the composite core is subjected to impregnation first and then is winded, so that the internal defects of a core rod caused by incomplete impregnation is prevented, so that the winding type composite core pultrusion impregnation process and the impregnation apparatus can be widely popularized.

Owner:FAR EAST CABLE +2

Electric vehicle packaging automatic sorting and conveying line

PendingCN109225904AKeep the air cleanGuaranteed cleanlinessDirt cleaningSortingElectric vehicleEngineering

The invention discloses an electric vehicle packaging automatic sorting and conveying line. The electric vehicle packaging automatic sorting and conveying line comprises a conveyor belt body, supportrods, and a first collecting box, wherein the conveyor belt body is mounted between the supporting rods through bolts, and a fixing groove is arranged on one side of the conveyor belt body, and a first inclined plate is arranged at the other side of the conveyor belt body, the inner side of the fixing groove is connected to a rotating plate through a rotating shaft, and one side of the rotating plate is connected to an electric telescopic rod through the rotating shaft, and the bottom end of the first inclined plate is connected to the first collecting box, a second inclined plate is arrangedat one end of the conveyor belt body, and the bottom end of the second inclined plate is connected to a second collecting box, and the first collecting box and the second collecting box are both provided with bearing plates and the bottoms of the bearing plates are provided with gravity sensors, and vibration alarms are mounted at the outer side of the support rods through a mounting bracket, andion fans are mounted at the inner side of the support rods by bolts. The electric vehicle packaging automatic sorting and conveying line provided by the invention has a high efficiency of sorting andconveying, and various functions, can meet the needs of use, and is convenient to use.

Owner:HUBEI XINRI ELECTRIC VEHICLE CO LTD

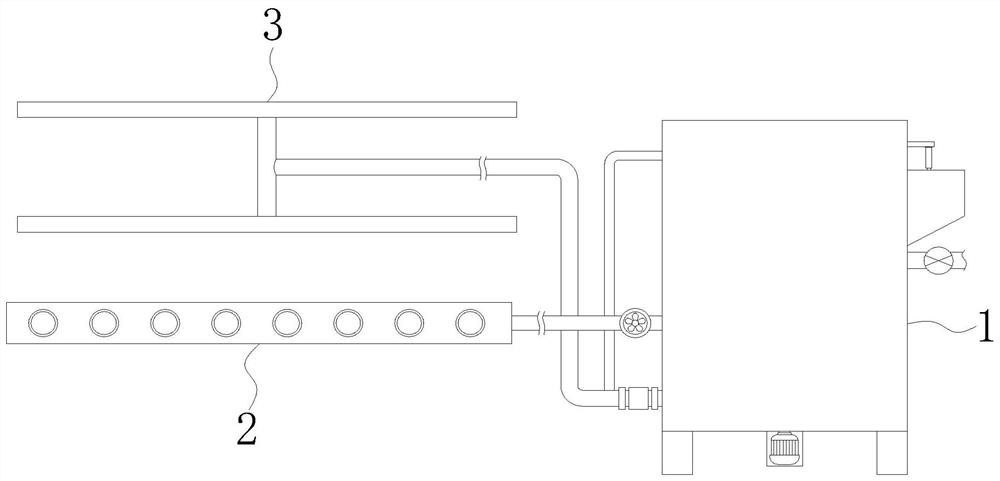

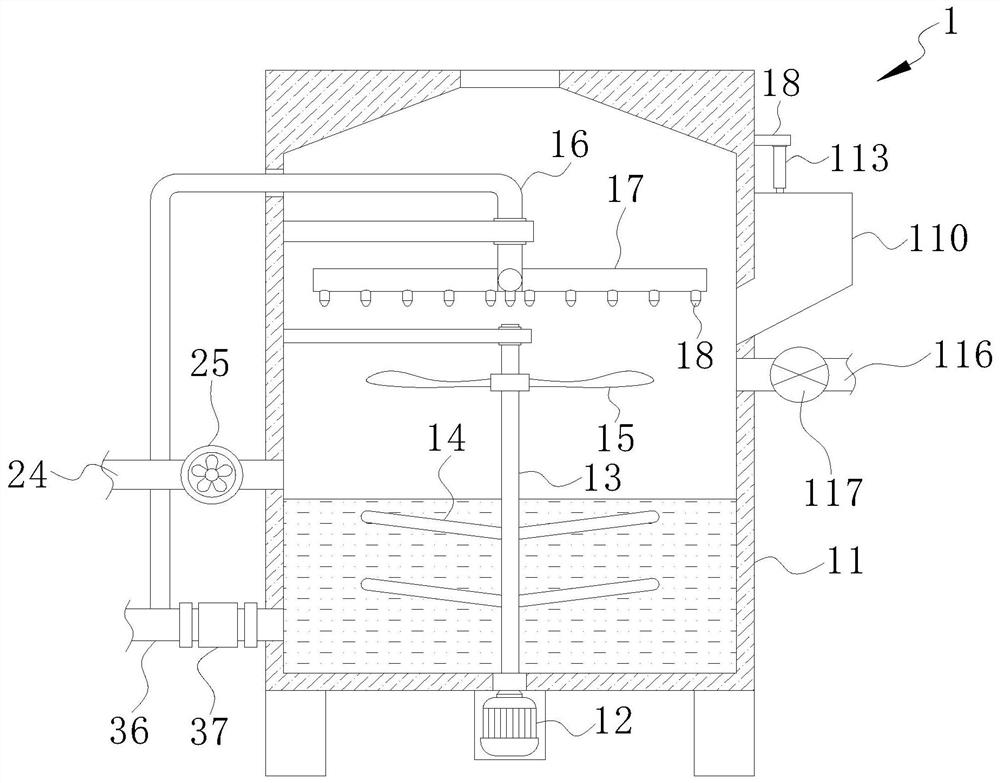

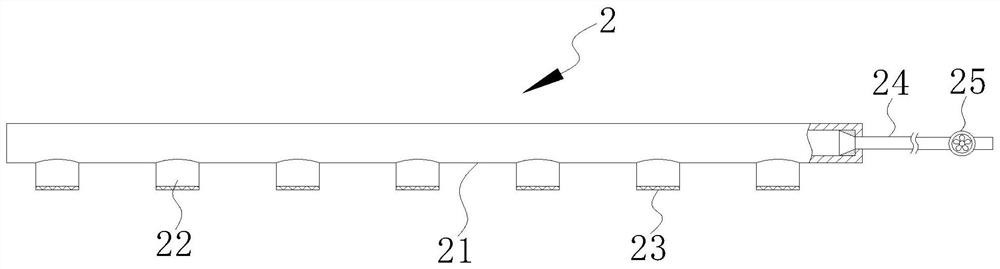

Heating device for flat plate shell material

The invention discloses a heating device for a flat plate shell material. The heating device for the flat plate shell material comprises a base, a main body box, a heating cabin and an air purifier, the main body box is arranged at the top of the base, the heating cabin is arranged in the main body box, and a spray nozzle is arranged on the inner top of the heating cabin. A stirring shaft is arranged in the heating cabin, stirring blades are arranged on the stirring shaft, and a ceramic heater is arranged on the inner side of the heating cabin. A discharging pipe is connected to the bottom ofthe heating cabin, an insulation cavity is formed in the outer surface of the heating cabin, electric heating ceramic is arranged in the insulation cavity, and an insulation sound-proof cotton layer is arranged on the outer surface of the insulation cavity, a motor is arranged at the top of the main body box and an output shaft of the motor is connected with the stirring shaft, a pressure pump isarranged on one side of the motor, and the air purifier is arranged on one side of the main body box. The heating device for the flat plate shell material is convenient to use, raw materials can be evenly heated, good insulation performance is achieved and the melted raw materials do not solidify, and the heating device is suitable for popularizing and using.

Owner:江苏金花朵电子科技有限公司

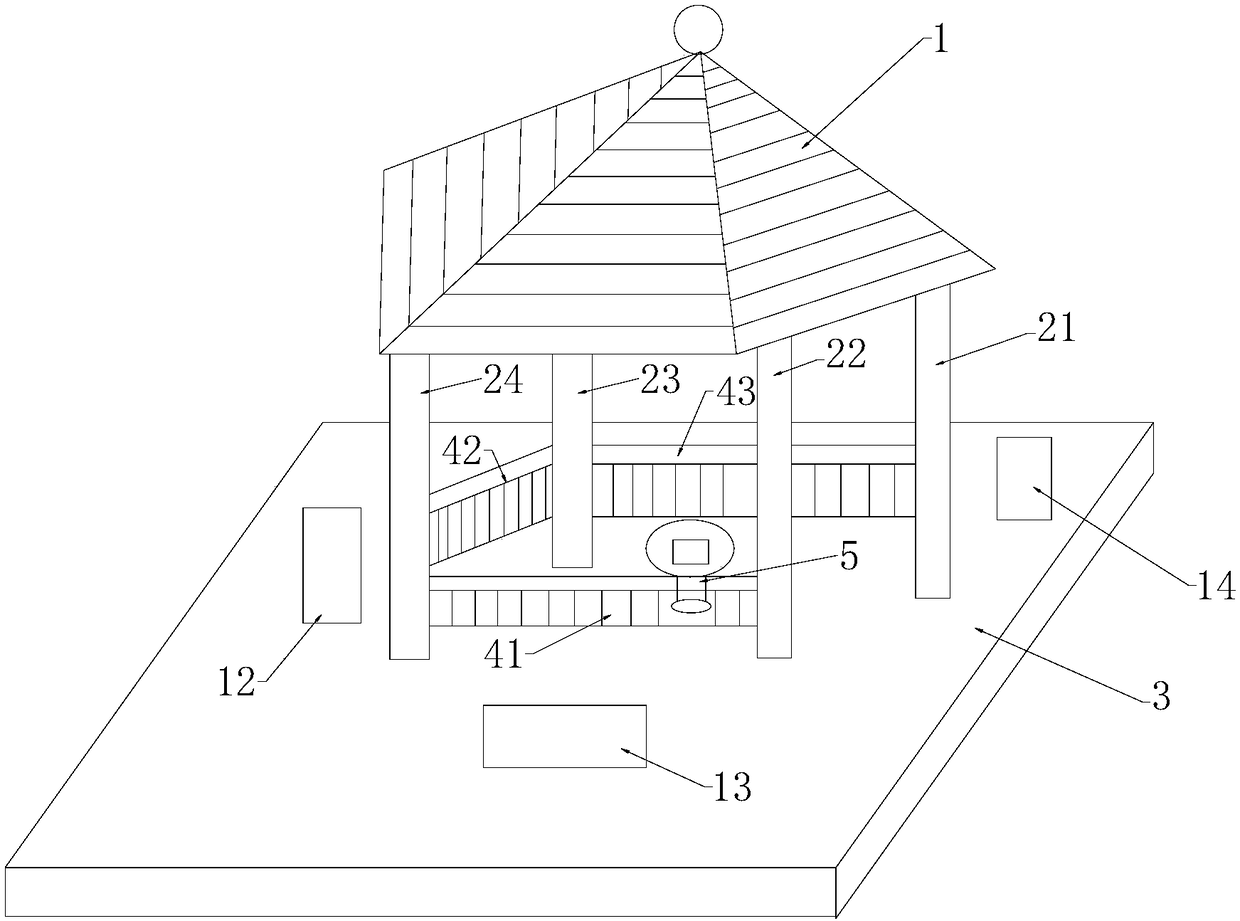

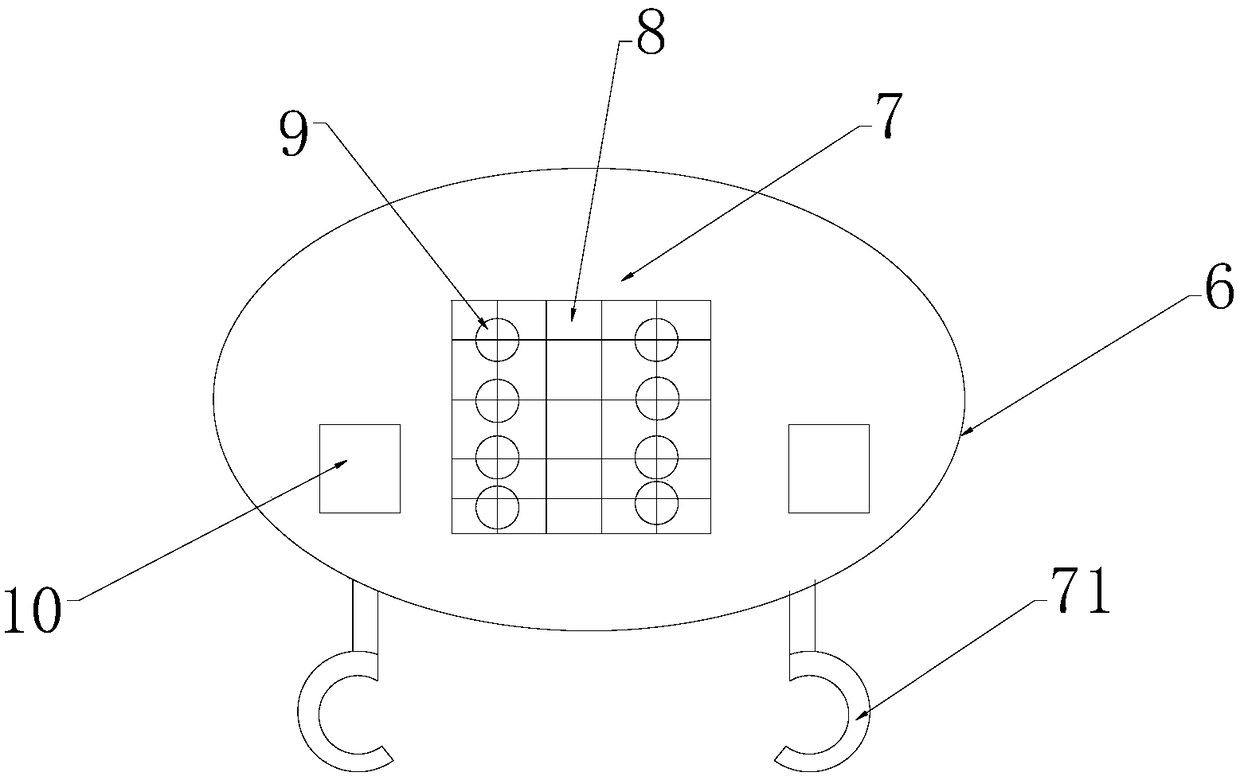

Landscape pavilion

InactiveCN108071244AKeep clean and hygienicKeep the air cleanRefuse receptaclesSpecial buildingBubble columnEngineering

The invention discloses a landscape pavilion which comprises a pavilion cover, four pavilion columns, a base, three rows of seats and a table. The four pavilion columns are vertically fixedly connected to the base, and the pavilion cover is connected to the upper ends of the four pavilion columns. The three rows of seats are fixedly arranged on the pavilion columns, and table columns are also vertically fixedly connected to the base. The table is arranged over the table columns. A chessboard and an ashtray device are arranged on the surface of the table, and the chessboard is fixedly connectedwith the table. An ashtray is inlaid into the surface of the table, and a hook device is further arranged at the lower edge of the table. The base is square and provided with an aquarium fish tank, an aquatic plant planting tank and a garbage cylinder. The landscape pavilion is simple in structure and tidy and aesthetic in appearance, serves as a landscape building, and also builds space communication so that people can rest in the pavilion and can gain happiness. Thus, the landscape pavilion has wide application prospects and is suitable for popularization on the market.

Owner:姜玉龙

Waste water utilizing type toilet bowl

InactiveCN101550720AReduced footprintKeep the air cleanWater closetsDomestic plumbingBall valveSewage

The invention relates to a waste water utilizing type toilet bowl comprising a toilet bowl, a water nozzle, an air feeding hole, a ball valve, a three-way prolonging pipe, a ball groove, a tee joint, an elbow tee joint, a waste water discharging pipe, a sewage pipe, an exhaust electric fan pipe, a ball hanging line, and the like, wherein the inner side of the edge of the toilet bowl is provided with the water nozzle and the air feeding hole which is annularly distributed, the lower end of the toilet bowl is connected with the ball valve, the lower end of the ball valve is connected with the three-way prolonging pipe, the exhaust electric fan pipe is connected with the three-way prolonging pipe which is connected with the sewage pipe and the waste water discharging pipe through the T joint, the sewage pipe is connected with the exhaust electric fan pipe and a water discharging total pipeline through the elbow tee joint, the bending position of the elbow Tee joint is an air blocking curved conduit, and the bending position of the waste water discharging pipe is a polluted water preventing backflow bending. The invention has small occupying area and odor removal, and the waste water can be secondarily utilized without collection.

Owner:陈林汝

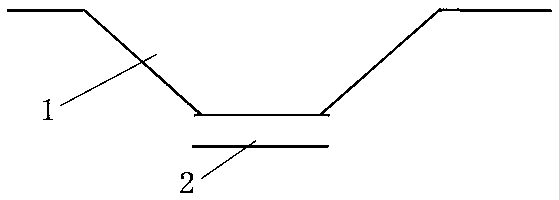

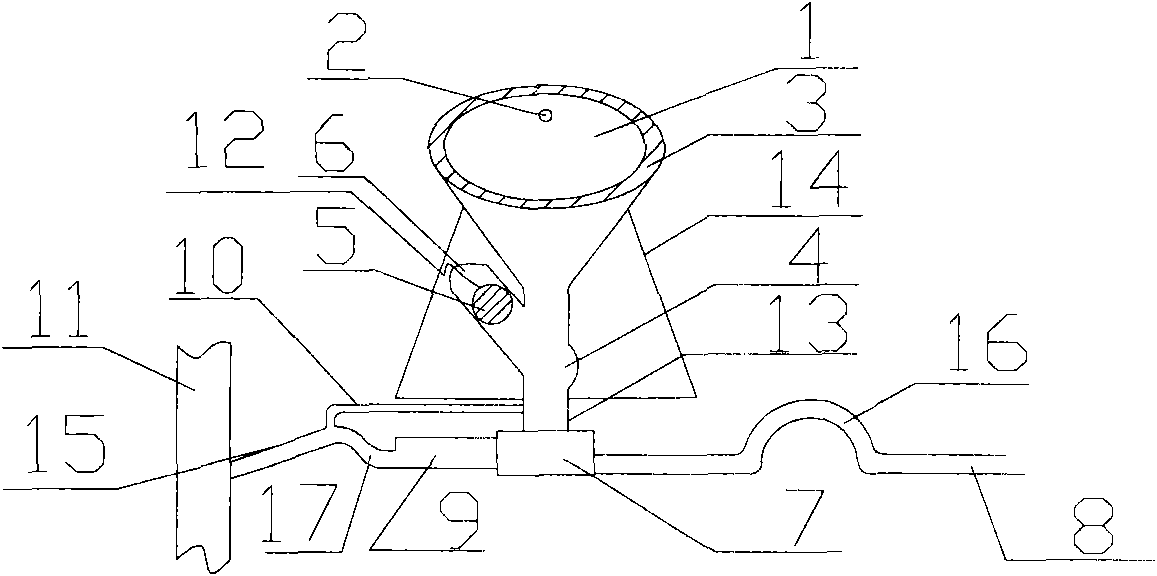

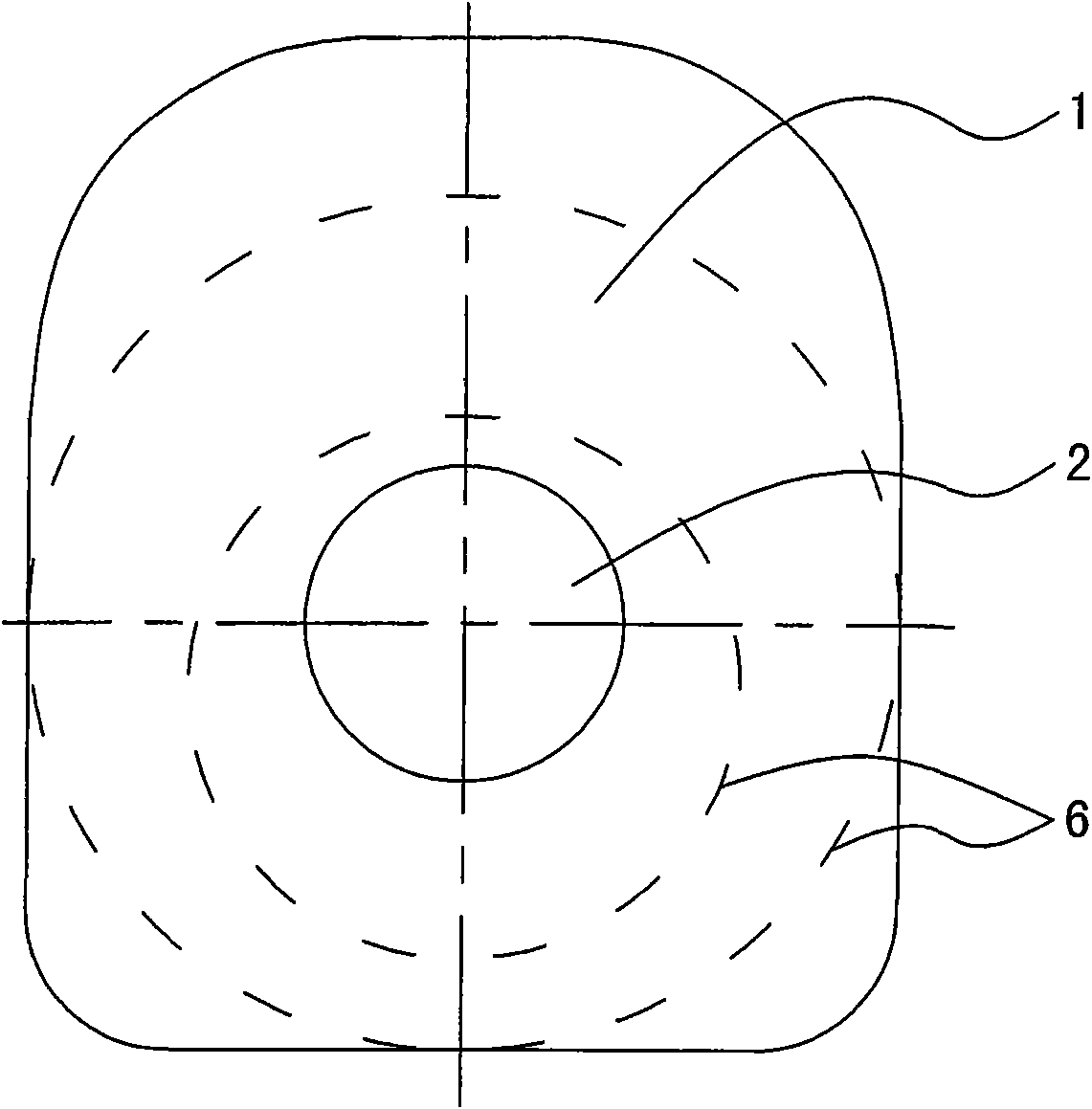

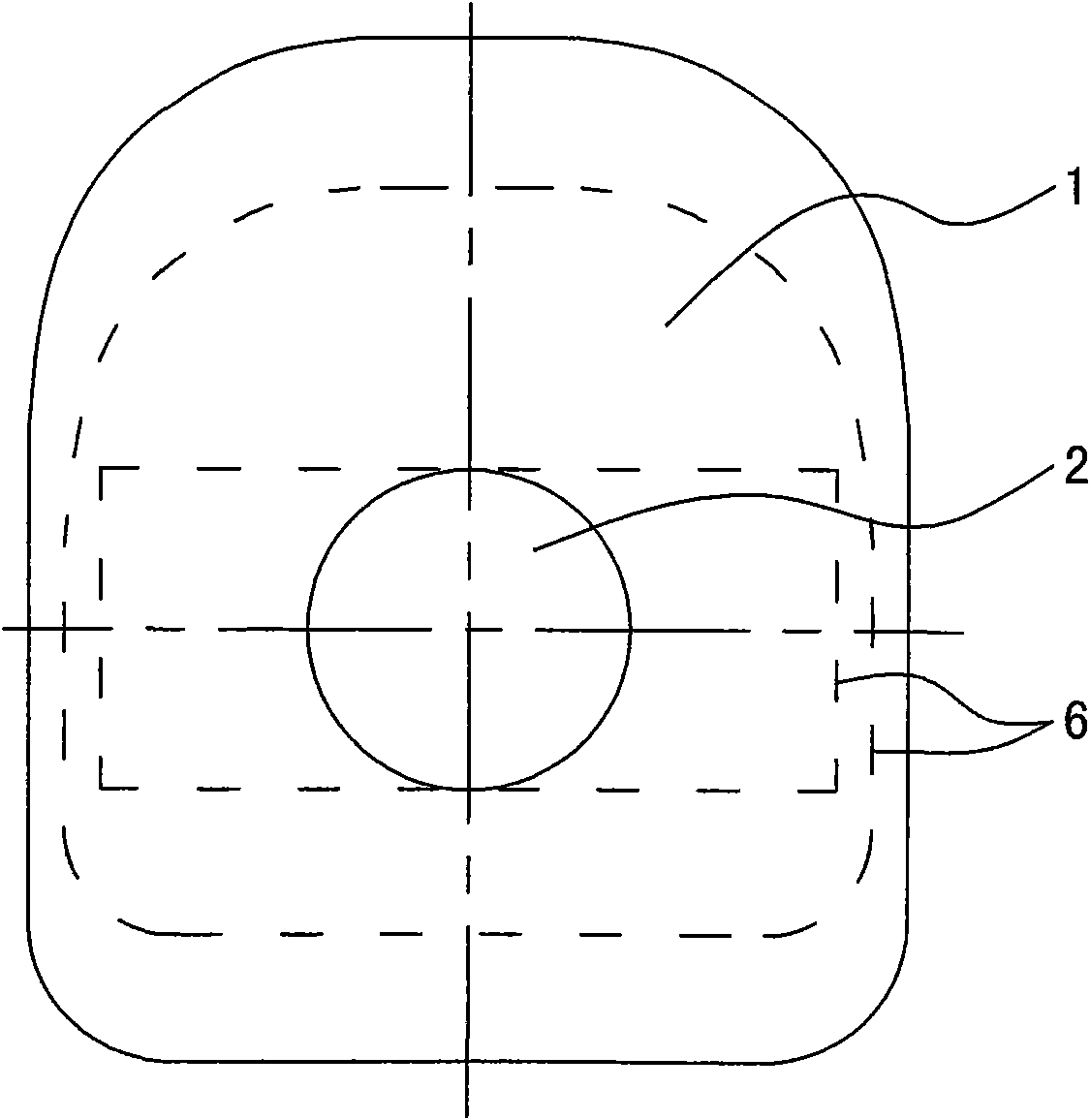

Blackboard eraser capable of sucking dust synchronously

InactiveCN104044389AKeep the air cleanReduce pollutionBoard cleaning devicesEngineeringNegative voltage

The invention discloses a blackboard eraser capable of sucking dust synchronously. The front end of a blackboard eraser body (1) is provided with a dust suction pipe (2). The dust suction pipe (2) is provided with a dust suction hole. The dust suction pipe is connected with a negative-voltage motor (3). A collection basket (4) is connected to the tail end of the pipe. In the using process, chalk dust generated during movement of the blackboard eraser body is collected to the collection basket (4) through the dust suction pipe. An induction module (5) is arranged on the collection basket (4). When the collection basket is almost filled with the chalk dust, the induction module sends out a prompt message. The prompt message is displayed in the mode of sound or LED lamp light. The dust suction pipe (2) is of a twistable structure, and the position of the dust suction pipe (2) can be adjusted as needed. The diameter of the dust suction hole in the dust suction pipe (2) should be smaller than one millimeter. The dust suction pipe (2) is provided with a dismantling connector to facilitate separate use of the blackboard eraser body. By means of the blackboard eraser capable of sucking the dust synchronously, the air in a classroom can be kept clean, dust pollution can be reduced, and a good learning environment can be provided for students.

Owner:ANHUI KANGCHENG IND PROD DESIGN

Breeding method for beef cattle

InactiveCN108244027AReduce odorAmmonia reductionAnimal feeding stuffAnimal housingParticulatesCorn flour

The invention discloses a breeding method for beef cattle. A fermentation liquid is prepared from 50g of a fermenting agent, 1kg of corn flour and 50kg of water, when the fermentation liquid is prepared, the fermenting agent, the corn flour and the water are mixed, and the mixed material is placed for one hour before being used; mixing of the fermenting agent, the corn flour and the water is performed by using a pneumatic motor, the pneumatic motor includes a roller body, a slewing bearing, a slewing bearing platform, and a ring-shaped sieve plate device, the slewing bearing platform is provided with a rustproof hole used for placing the slewing bearing, and the slewing bearing is in hoop connection with the roller body and is filled into the rustproof hole from one end of the rustproof hole. The method provided by the invention avoids the problem that particle impurities rush into the rustproof hole and the slewing bearing, so that the slewing bearing is destroyed in the prior art.

Owner:JIANGSU AGRI ANIMAL HUSBANDRY VOCATIONAL COLLEGE

Odor blocking and degerming device for flush toilet

The invention relates to an odor blocking and degerming device for a flush toilet, which is characterized by comprising a fixed plate. The middle part of the fixed plate is provided with a through hole; a flexible sealing sheet is connected to one side at the bottom of the fixed plate; the edges of the fixed plate is attached to the inner wall of the flush toilet; and the upper surface of the fixed plate is arranged below the accumulated water level of the flush toilet. The technical scheme of the invention has the following advantages: 1. the odor of accumulated water in the flush toilet and sewers does not come up, thereby keeping air in bathrooms clean; 2. the accumulated water is separated from air, thereby inhibiting the reproduction and growth of bacteria, preventing disease from spreading during the moving of flies, mosquitoes, cockroaches and rats; 3.float left after flushing does not come up to the water level and does not to be flushed again, thereby saving water; 4. excrement impacts on the fixed plate and the sealing sheet without water splashing; and 5. the device is switched on / off automatically and can be used conveniently.

Owner:任金勇 +1

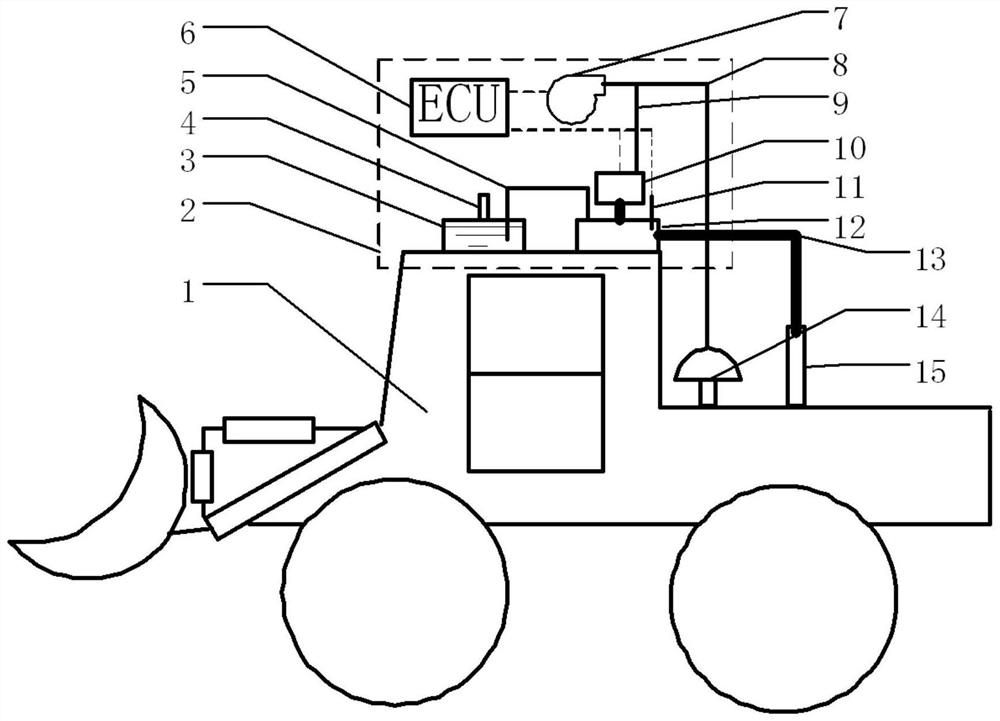

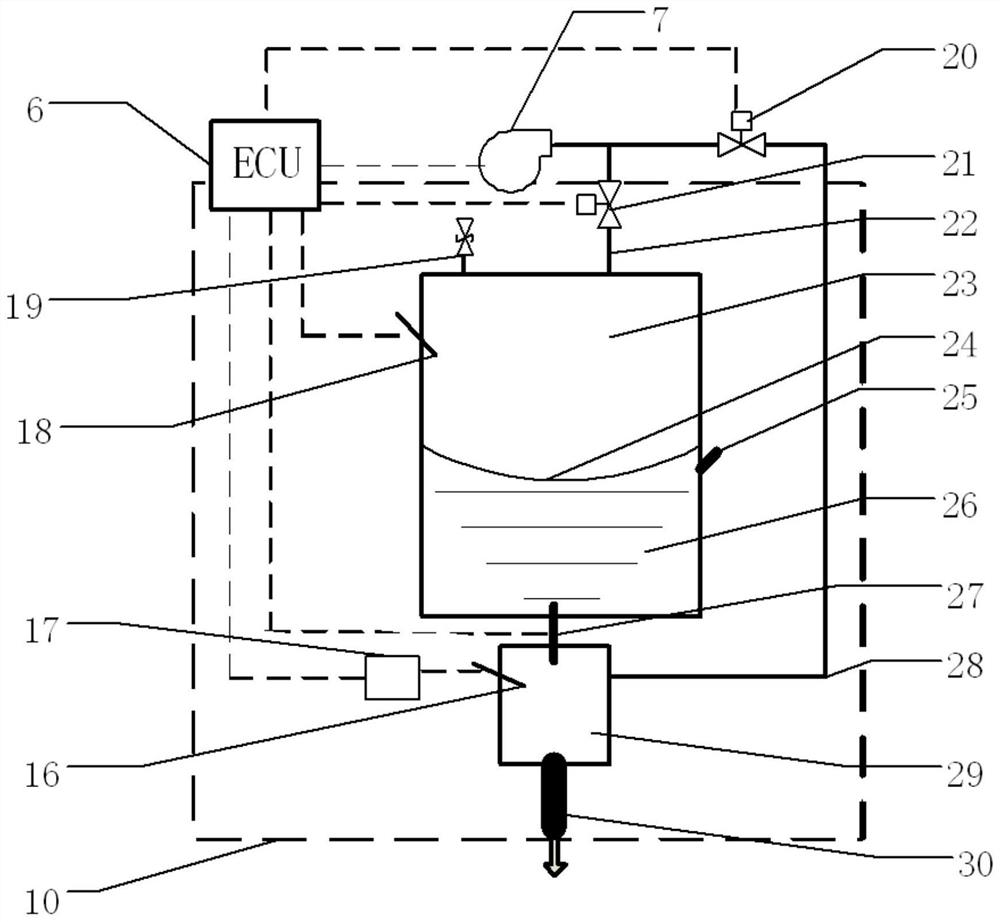

Tail gas purification device for tunnel construction machinery

InactiveCN114526139AKeep the air cleanKeep healthyInternal combustion piston enginesExhaust apparatusCombustion chamberControl system

The invention discloses a tail gas purification device for tunnel construction machinery, which is characterized in that a tail gas purification mechanism is arranged at the top of a loader, a fuel tank compressed air chamber is arranged at the top of the inner side of a fuel system, and the bottom of the fuel tank compressed air chamber is connected with a fuel tank fuel chamber; engine exhaust pollutants enter the combustion chamber of the tail gas purification mechanism, if a control system detects that the temperature is lower than 600 DEG C, fuel is injected for ignition and combustion, the temperature of the combustion chamber is maintained to be 600 DEG C or above, and after soot particles and harmful substances in engine exhaust are fully combusted in the combustion chamber, the soot particles and the harmful substances are discharged into the purification box. The exhaust gas is absorbed and purified by the weakly alkaline liquid and converted into clean gas to be exhausted into the atmosphere of the tunnel, so that the air in the tunnel is kept clean, the body health of constructors is guaranteed, accurate control is achieved through the simple structure, the purification efficiency in the tunnel is improved, meanwhile, the production cost is low, and popularization and implementation are convenient.

Owner:NORTH CHINA INST OF AEROSPACE ENG

Environment-friendly toilet paper processing method

PendingCN112962352AQuality improvementWell mixedNon-fibrous pulp additionSpecial paperPulp treatmentNitrifying bacteria

The invention belongs to the technical field of toilet paper processing, and particularly relates to an environment-friendly toilet paper processing method which comprises the following steps: S1, pulping: adding large shaft paper into a pulverizer for pulverizing treatment, and adding a proper amount of clear water in the pulverizing process to obtain pulp; S2, pulping: adding the pulp into a grinding machine for pulping treatment, uniformly grinding the pulp, and gradually adding a proper amount of nitrifying bacteria in the grinding process; S3, drying: adding the pulp into a drying machine for drying until water is completely removed to obtain a toilet paper semi-finished product; S4, rewinding and paper cutting: subjecting the semi-finished toilet paper to rewinding and paper cutting treatment; and S5, heating and sterilizing. The preparation steps are simple and convenient, the quality of the toilet paper is improved, ammonia gas and hydrogen sulfide can be quickly removed, air in a toilet is ensured to be clean, no whitening agent is added, the safety during use is ensured, and the environmental protection property is good.

Owner:HEBEI YIHOUCHENG COMMODITY CO LTD

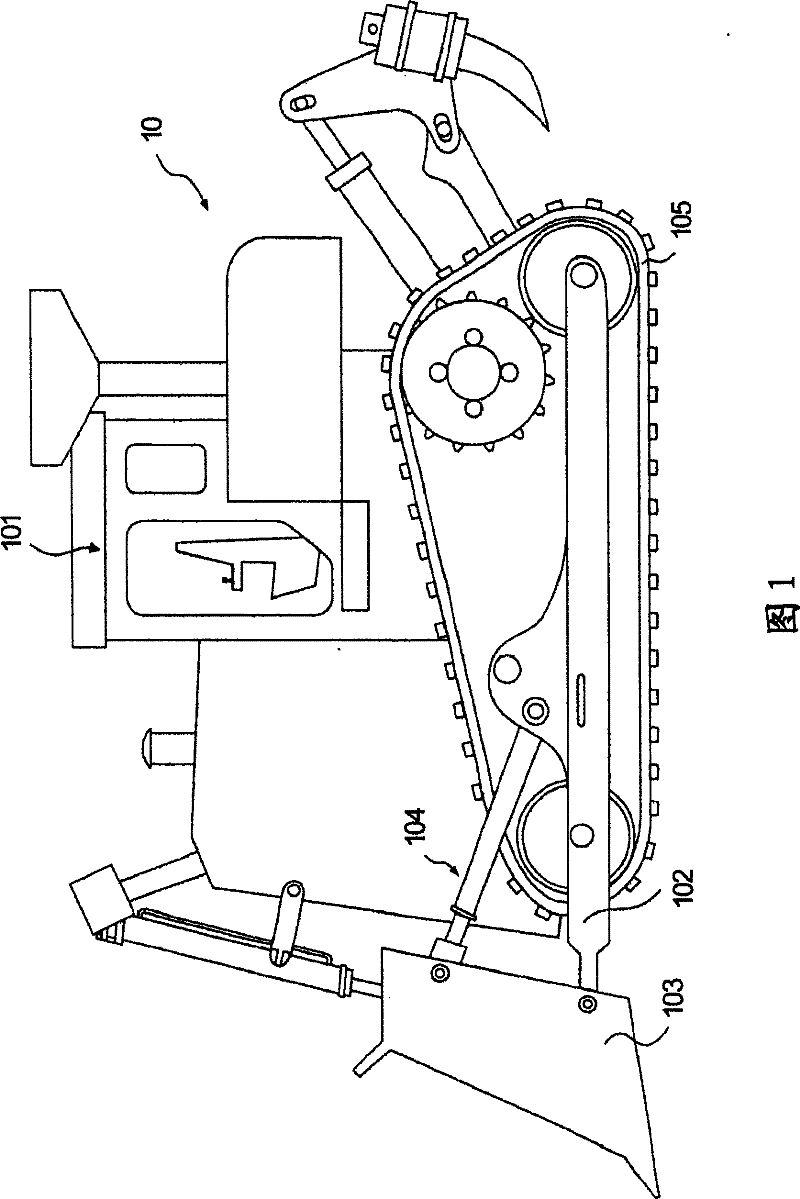

Sealing device for working machine and pressurized driving cap

InactiveCN101135173BAvoid pollutionAvoid damageSoil-shifting machines/dredgersMechanical engineeringContamination

The sealed and pressurized operator's cabin for engineering machinery includes one sealed box comprising one first part with at least one first opening and one second part with at least one second opening; at least one control rod connected to the sealed box and penetrating through the first opening; at least one linkage unit connected to the control rod and penetrating through the second opening; and one sealing member to seal the sealed box through fitting with the linkage unit. The sealed and pressurized operator's cabin can avoid contamination to the inside of the cabin and maintain its air pressure.

Owner:CATERPILLAR INC

Garbage dehydration solid-liquid separation device

The invention discloses a rubbish dehydration solid-liquid separation device. The rubbish dehydration solid-liquid separation device comprises a closed solid-liquid separation cylinder body, a downward-moving hydraulic system with a lower push plate, a discharging hydraulic system with a discharging push plate and an upward-moving hydraulic system with an upper push plate. A feeding opening and a discharging opening are formed in the upper portion of the solid-liquid separation cylinder body. The lower push plate of the downward-moving hydraulic system is arranged on the top of the solid-liquid separation cylinder body and can move up and down along an inner cavity of the solid-liquid separation cylinder body. The upper push plate of the upward-moving hydraulic system is arranged at the bottom of the solid-liquid separation cylinder body and can move up and down along the inner cavity of the solid-liquid separation cylinder body. The discharging push plate of the discharging hydraulic system is arranged at the position, corresponding to the discharging opening, of the solid-liquid separation cylinder body, and can make transverse movement along the inner cavity of the solid-liquid separation cylinder body. According to the rubbish dehydration solid-liquid separation device, a double-direction vertical hydraulic squeezing mode is adopted, powerful squeezing can be provided, the problems of winding and hard object sticking in material dehydration can be solved, the adaptability to materials is high, the effects of rubbish reduction and volume reduction are obvious, the automation degree is high, and sealed deodorization can be achieved.

Owner:BEIJING JIELV ENVIRONMENTAL TECH CO LTD

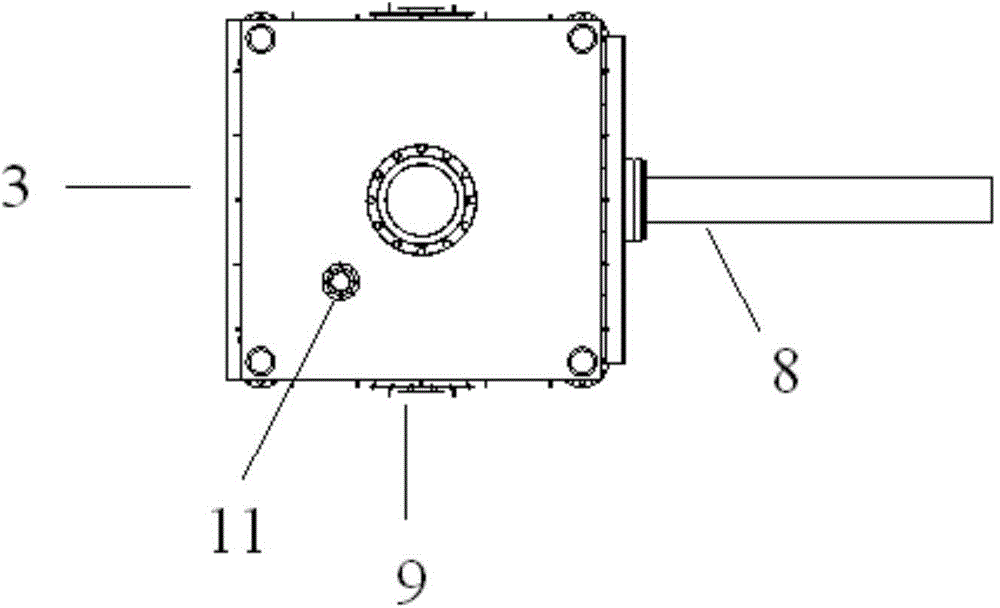

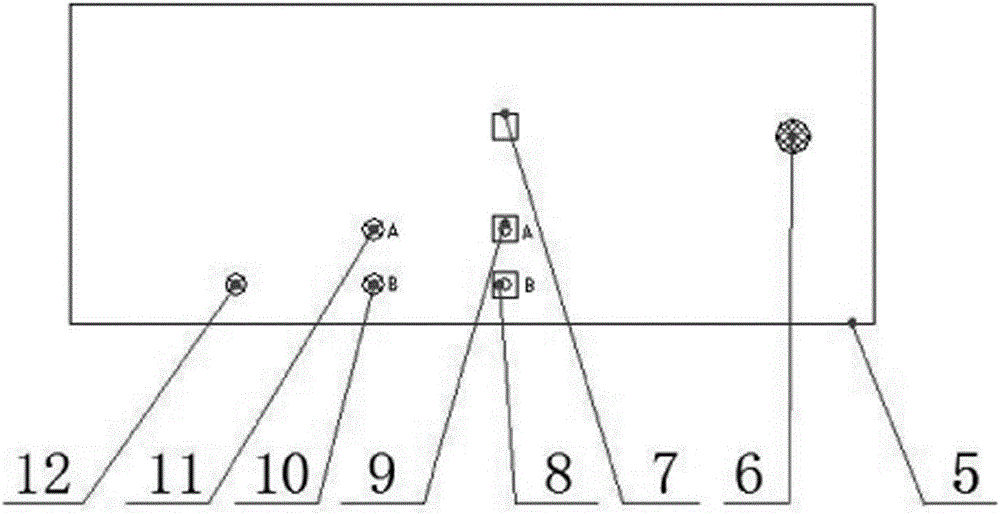

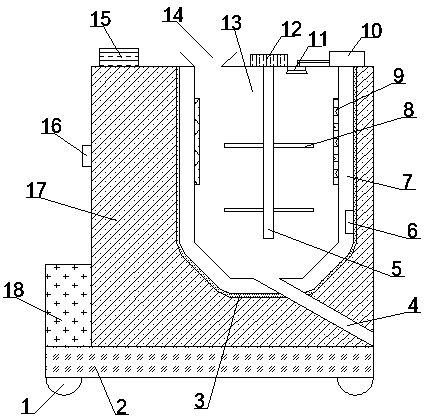

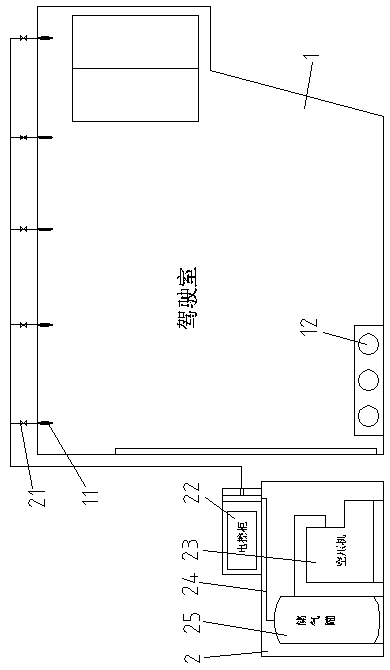

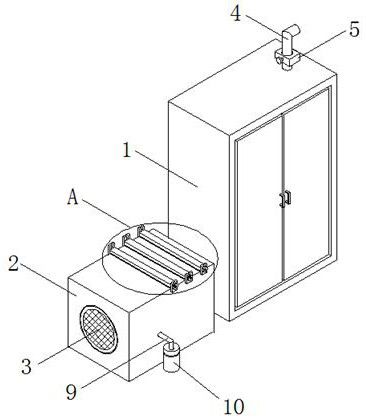

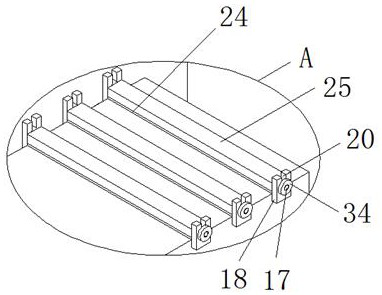

Air supply device of hospital clean operating room

InactiveCN108088003ARealize the loop functionRealize the purification functionMechanical apparatusLighting and heating apparatusAir cycleEngineering

The invention discloses an air supply device of a hospital clean operating room. The air supply device comprises an air suction air box, an air inlet grid plate is arranged at the lower end of the airsuction air box, and the air suction air box is connected in an air outlet air box in a sleeved mode; air outlets are formed in the inner side of the air outlet air box and the outer side of the airsuction air box, and the upper end of the air suction air box is connected with an air suction device; the upper end of the air suction device is connected with an air outlet pipe, and the air outletpipe is connected with air inlet pipes through three-way valves; and the air inlet pipes are connected with air purification treatment boxes, and the air purification treatment boxes communicate withthe air outlet air box. According to the air supply device of the hospital clean operating room, the structure is stable, use is convenient, air circulation and purification functions of the operatingroom can be realized, air in the operating room can be guaranteed to be cleaned, and bacteria in the air can be effectively sterilized and disinfected, so that functions are complete, operation is convenient, and existing use requirements are met.

Owner:韩楠

Odor treatment system for hazardous waste combustion plant

PendingCN112246072ATo achieve the effect of dust reductionEffective deodorizing effectCombination devicesGas treatmentElectric machineryEnvironmental engineering

The invention relates to the technical field of hazardous waste combustion, and discloses an odor treatment system for a hazardous waste combustion plant; wherein the odor treatment system comprises an odor recovery treatment mechanism, an odor suction mechanism and a spraying odor removal mechanism, the odor recovery treatment mechanism comprises a treatment box body, an exhaust port is formed inthe top of the treatment box body, and a motor is fixedly mounted on the inner bottom wall of the treatment box body; an output shaft of the motor penetrates through the bottom of the treatment box body and is fixedly provided with a rotating rod, two sets of stirring rods and fan blades are fixed to the outer circle face of the rotating rod, and the upper end of the rotating rod is arranged on the inner side wall of the treatment box body through a fixing frame; the outer circle face of the end, located in the treatment box body, of the branch pipe communicates with four evenly-distributed transverse pipes. The invention solves the problems that the odor of the dumping platform of the hazardous waste garbage truck of the existing hazardous waste combustion plant cannot be effectively treated, the work of workers is influenced, and the environment is polluted.

Owner:ANHUI WANSHANHONG ENVIRONMENTAL PROTECTION TECH CO LTD

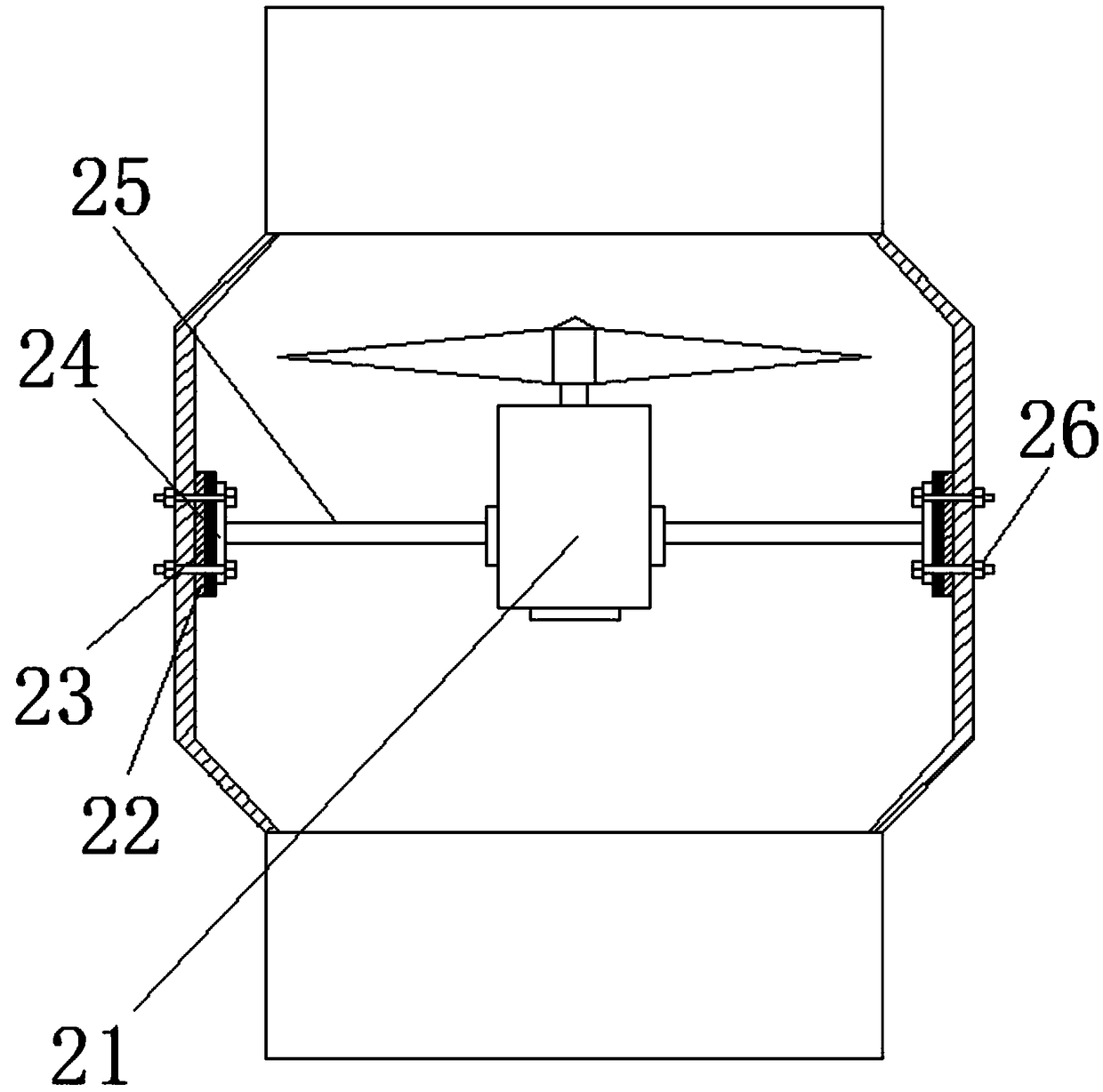

Micro-positive pressure dust isolation system

PendingCN108421318AAvoid enteringKeep the air cleanDispersed particle filtrationTransportation and packagingAir filterPositive pressure

The invention discloses a micro-positive pressure dust isolation system. An air storage tank, an air compressor, an air duct and a pressure regulating valve are mounted in an isolation tank casing onan equipment platform; air pressure in the air storage tank is adjusted to be a micro-positive pressure state, and then air enters a driving cab; air filters and back flushing devices are mounted on the side walls of the two sides of the isolation tank casing; an electric control cabinet is mounted at the top of an isolation tank; an air inlet is formed in the upper part of the top of the drivingcab; an air outlet is formed in the lower part of the top of the driving cab; pressure of clean air subjected to dust removal through filtering of the air filters is adjusted to be micro-positive pressure, and then the clean air is connected with and conveyed to the interior of the driving cab, so that air pressure in the driving cab always keeps a micro-positive pressure state slightly higher than that of the outside. The system can isolate dust outside the driving cab, prevent dust from entering the equipment driving cab, keep environmental health of air in the driving cab, and reduce the equipment maintenance workload, and is convenient in mounting operation; the system device can be further applied to all other similar dynamic and static equipment requiring dust isolation and places, such as site work and rest rooms, surrounded by dust.

Owner:JIANGSU SUYADI CARBON MATERIAL CO LTD

Intelligent manhole cover for solving urban air pollution

InactiveCN108005219AEliminate heavy air pollutionKeep the air cleanSewerage structuresExhaust gasInductor

The invention discloses an intelligent manhole cover for solving urban air pollution. The intelligent manhole cover comprises a manhole cover base and a manhole cover body arranged at the upper end ofthe manhole cover base; at least one exhaust port and a water leakage port are formed inside the manhole cover base, the edge of the water leakage port and the exhaust port extend upwards to form a boss, the exhaust boss is sequentially provided with a magnetic valve, an exhaust fan and a rainproof cover which are sequentially arranged from bottom to top and are in seamless connection with the manhole cover base; the rainproof cover is arranged at the top end of the exhaust boss and is composed of a plurality of movable blades. A nitric oxide inductor, a sulfur dioxide inductor, a PM2.5 inductor and the like are arranged inside the manhole cover body, the inductors control a magnetic valve and the rainproof cover to be turned on or off and the exhaust fan to be operated. The intelligent manhole cover has the deodorization and odor removal functions, multi-layer protection is arranged so as to avoid safety accidents, the manhole cover can be applied to air pollution places such as a road section with high automobile exhaust, a mud dust road and a chemical plant, heavy air pollution can be rapidly eliminated, and the air can be kept clean durably.

Owner:康云生

Device for performing singeing process on textile

InactiveCN112726081AReduced risk of damaging textile fabricsKeep the air cleanDispersed particle filtrationSingeingExhaust fumesEngineering

The invention discloses a device for performing a singeing process on a textile. The device comprises a main box body; a singeing cavity is formed in the main box body; a ventilation cavity is formed in the upper side of the singeing cavity in a communicating mode; a waste gas filter screen is fixedly connected to the inner wall of the ventilation cavity; a fan base located on the upper side of the waste gas filter screen is connected inside the inner wall of the ventilation cavity in a running fit mode; and a fan cavity which is through vertically is formed in the fan base. According to the device, heating rollers heated on the upper side and the lower side rotate in the same direction, so that fluff on the upper surface and the lower surface of the textile is singed to be clean; naked flame is replaced to treat the fluff, so that the safety of the device is greatly improved and the risk that the naked flame damages textile cloth is reduced; through a movable recycling shaft, the end, starting to be processed, of textile cloth is ensured to be processed; and meanwhile, through a fan rotating on the upper side of the singeing cavity, polluted gas generated in the singeing cavity is discharged to the outside through the filtering effect of the waste gas filter screen, so that the air cleanness of a working environment is ensured and the body health of operators is ensured.

Owner:代燕燕

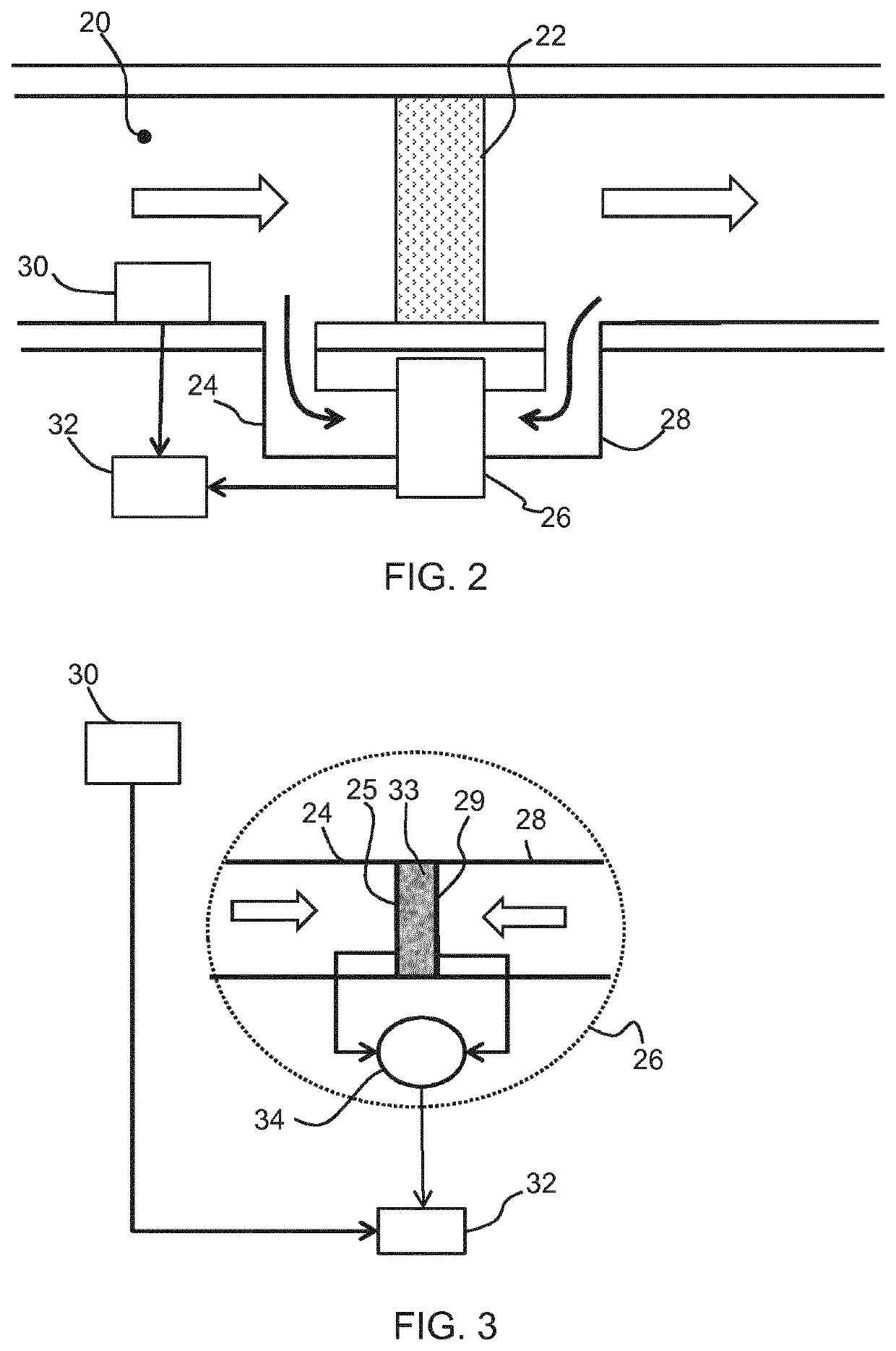

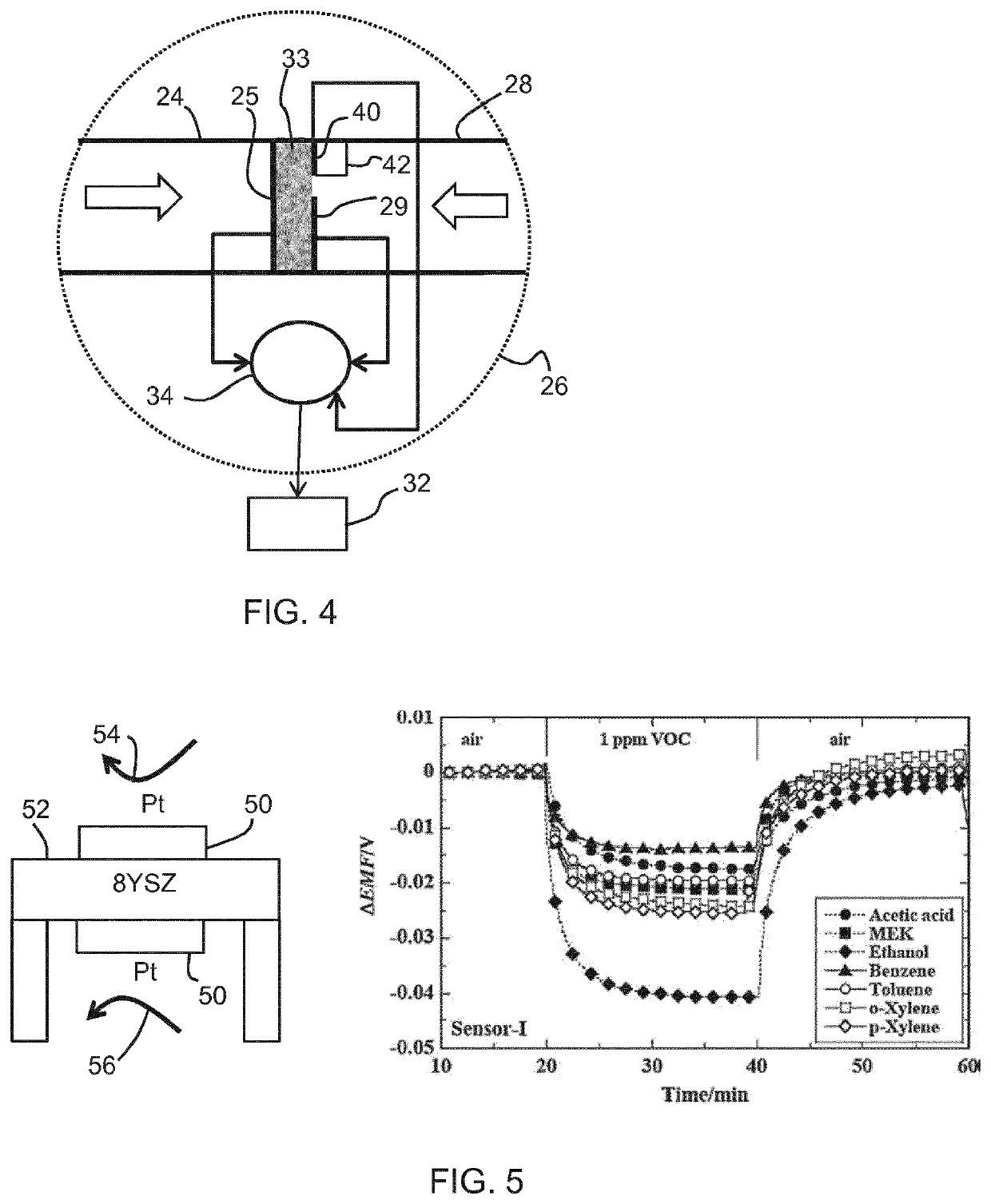

Air purifier and air purification method

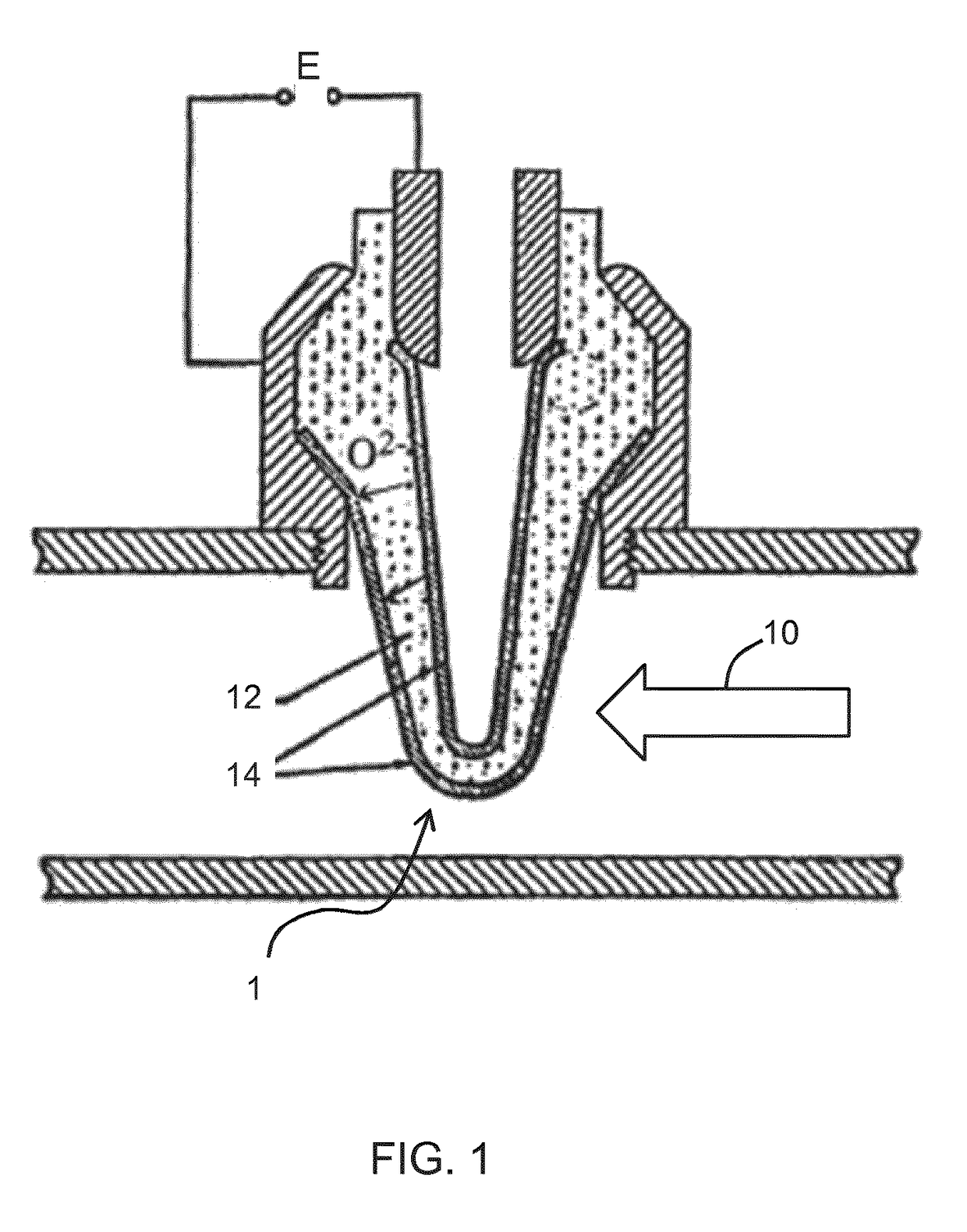

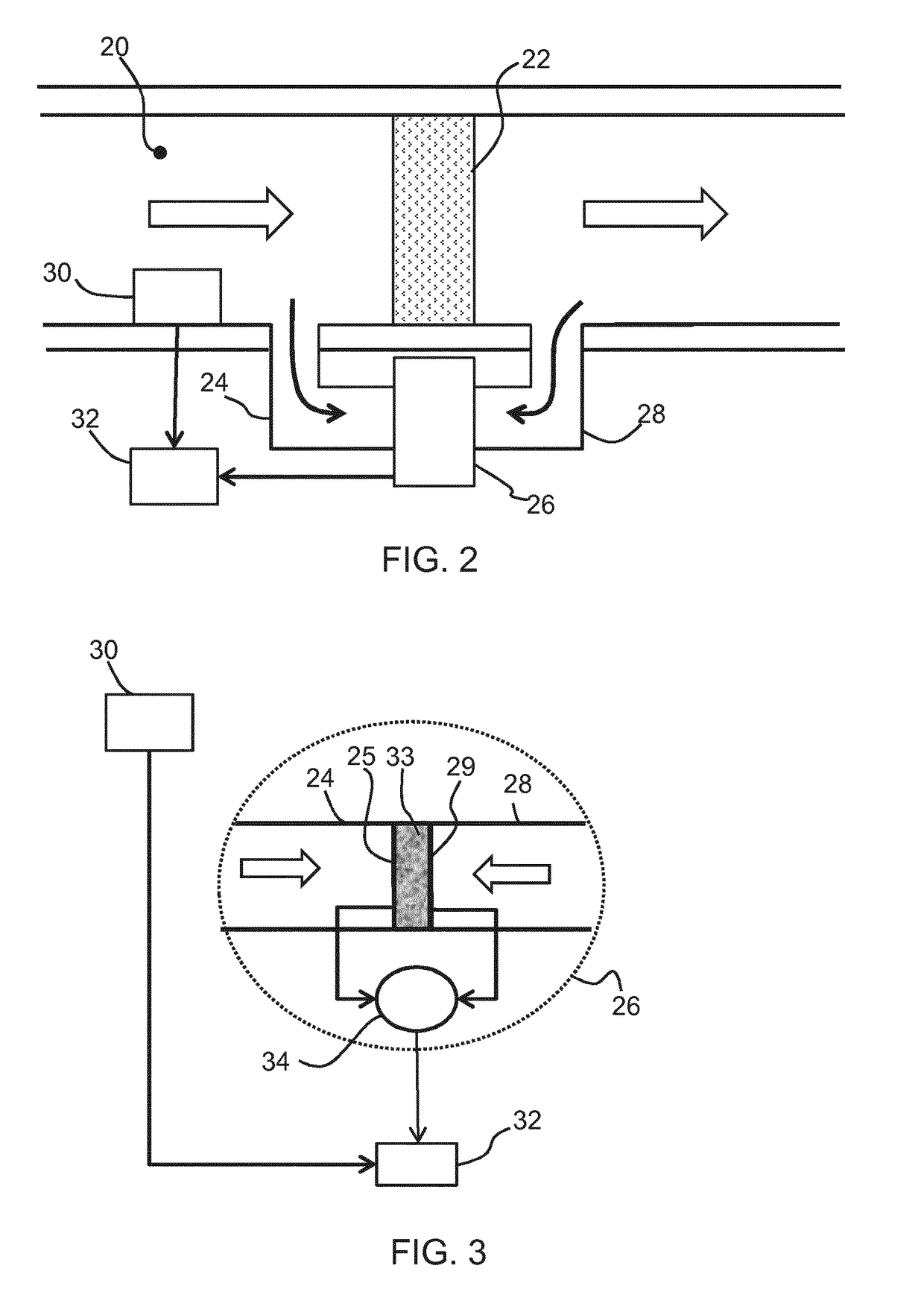

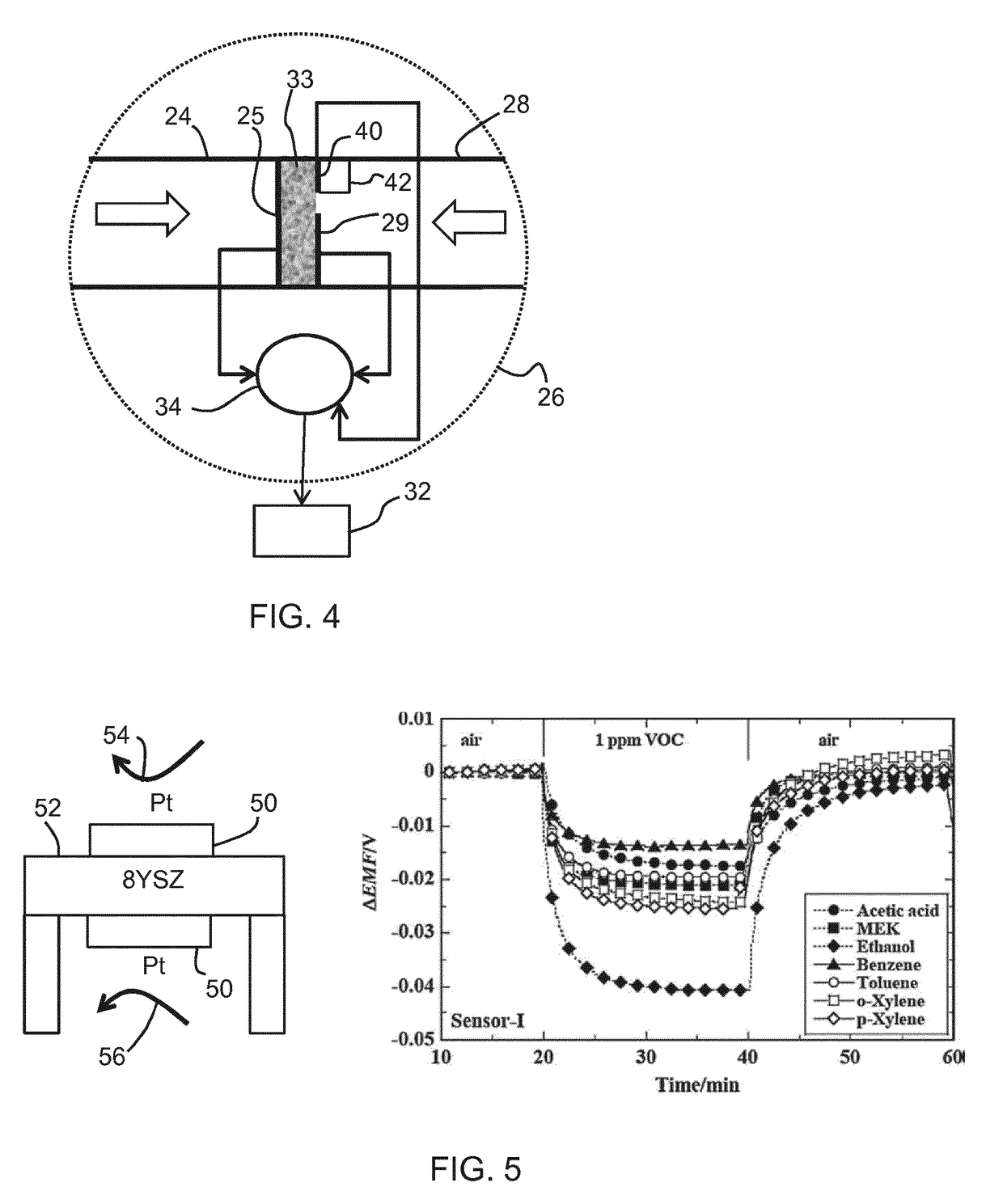

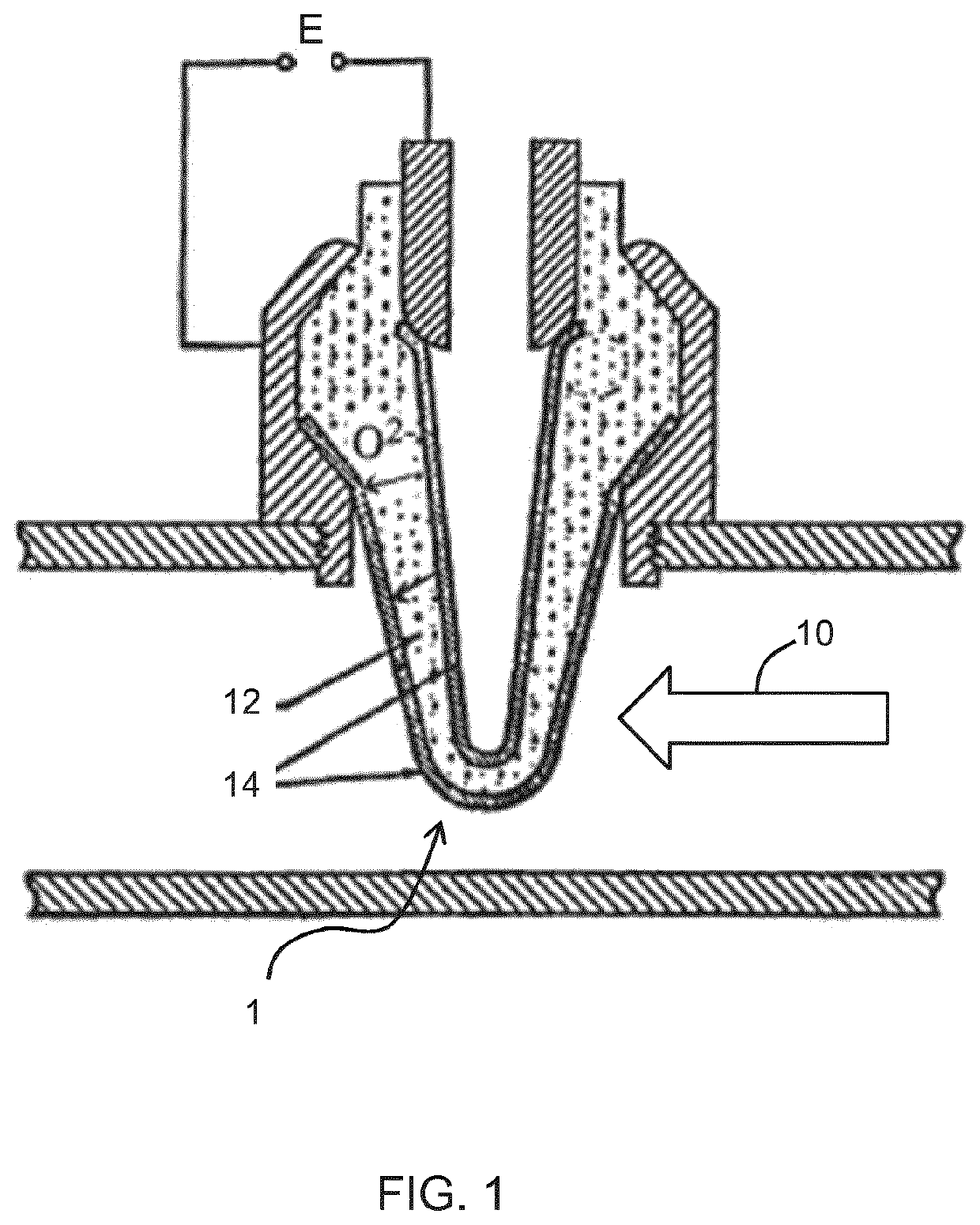

ActiveUS20190078802A1Avoid needLow costMechanical apparatusSpace heating and ventilation safety systemsAirflowEngineering

An air purifier comprise a gas filter between an upstream air flow and a downstream air flow and a concentration sensor comprising a first electrode and a second electrode, the first electrode being exposed to the upstream air flow and the second electrode exposed to the downstream air flow, the concentration sensor providing an output signal based on the difference in concentrations of a target gas at the first and second electrodes. The output signal is processed to determine information relating to the con- dition of the gas filter.

Owner:KONINKLJIJKE PHILIPS NV

Air purifier and air purification method

ActiveUS10948207B2Low costAccurately determineMechanical apparatusSpace heating and ventilation safety systemsAir purifiersAir cleaning

An air purifier comprise a gas filter between an upstream air flow and a downstream air flow and a concentration sensor comprising a first electrode and a second electrode, the first electrode being exposed to the upstream air flow and the second electrode exposed to the downstream air flow, the concentration sensor providing an output signal based on the difference in concentrations of a target gas at the first and second electrodes. The output signal is processed to determine information relating to the condition of the gas filter.

Owner:VERSUNI HLDG BV

Chemical reagent cabinet with air filtering device

PendingCN113877639AKeep the air cleanEasy to install and removeCombination devicesEnclosures/chambersAir pumpEnvironmental engineering

Owner:天长市万宏实验仪器设备有限公司

A winding composite core pultrusion impregnation process for smart energy and its special impregnation device

The invention discloses a winding type composite core pultrusion impregnation process for smart energy and a special impregnation apparatus therefor. The impregnation apparatus comprises a first yarn-splitting frame, a first impregnation groove, a first adhesive extruding roller, a second yarn-splitting frame, an adhesive scraper, a first yarn collector, a winder, a pre-curing die, a curing die, a second impregnation groove, a second adhesive extruding roller and a second yarn collector that are arranged on a tooling bracket, wherein an upper yarn-splitting device and a lower yarn-splitting device are arranged at the upper and lower ends of the first yarn-splitting frame respectively; the first adhesive extruding roller and the second adhesive extruding roller are arranged at the upper parts of the first impregnation groove and the second impregnation groove respectively; the second yarn-splitting frame and the adhesive scraper are arranged at the front part of the first yarn collector; the first yarn collector is arranged at the front part of the winder; and the winder is arranged at the front part of the pre-curing die. According to the winding type composite core pultrusion impregnation process and the impregnation apparatus, continuous winding can be realized through the winder so as to produce the winding type composite core; the composite core is under transverse protection, so that the cracking of the composite core is avoided, and the composite core is safer to use; and in addition, the composite core is subjected to impregnation first and then is winded, so that the internal defects of a core rod caused by incomplete impregnation is prevented, so that the winding type composite core pultrusion impregnation process and the impregnation apparatus can be widely popularized.

Owner:FAR EAST CABLE +2

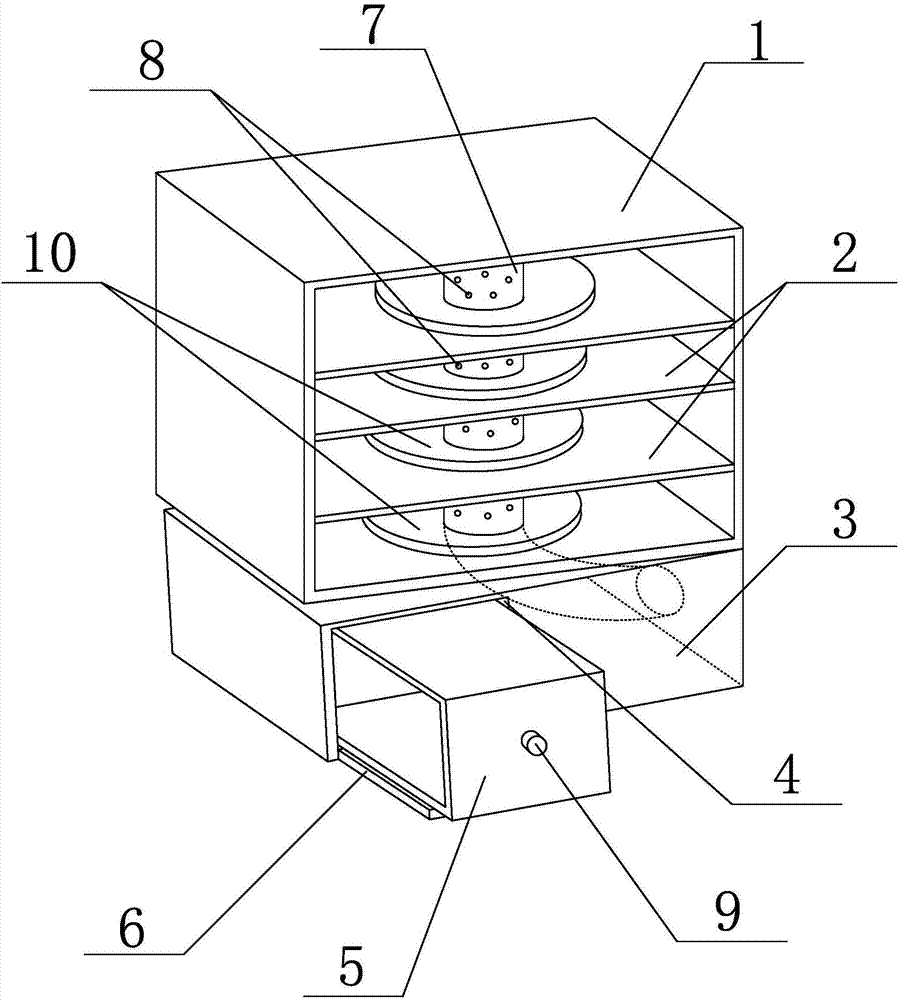

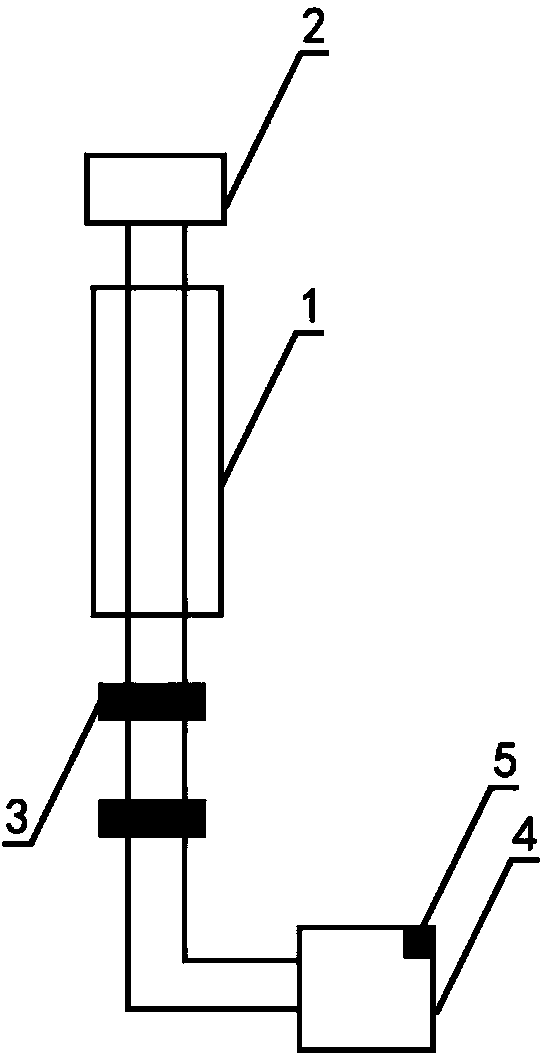

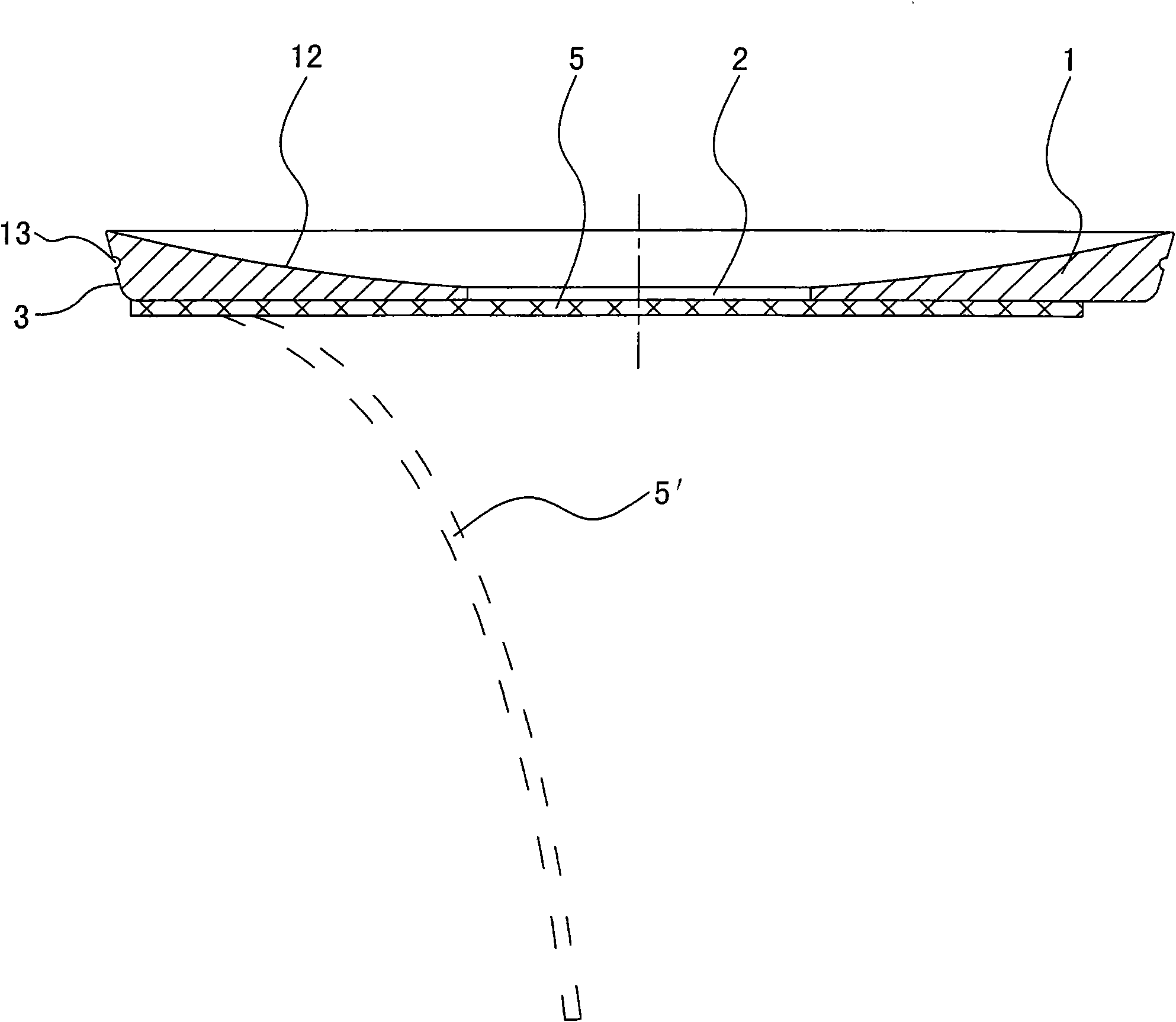

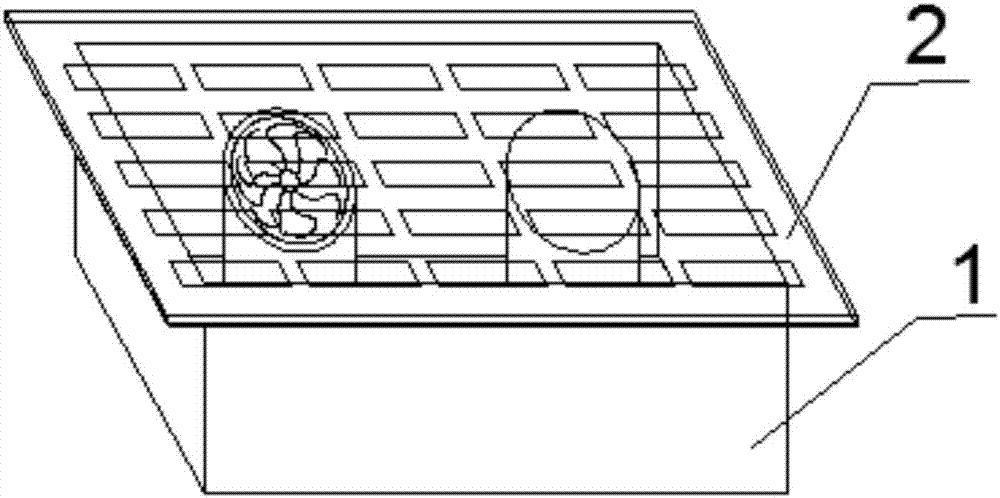

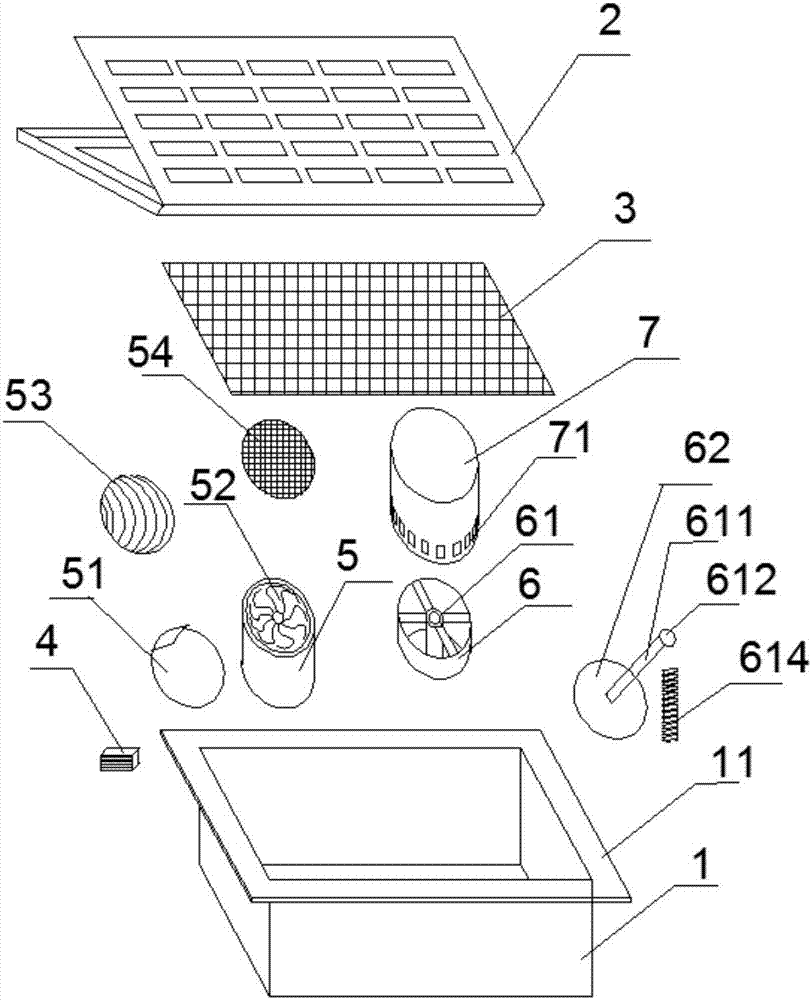

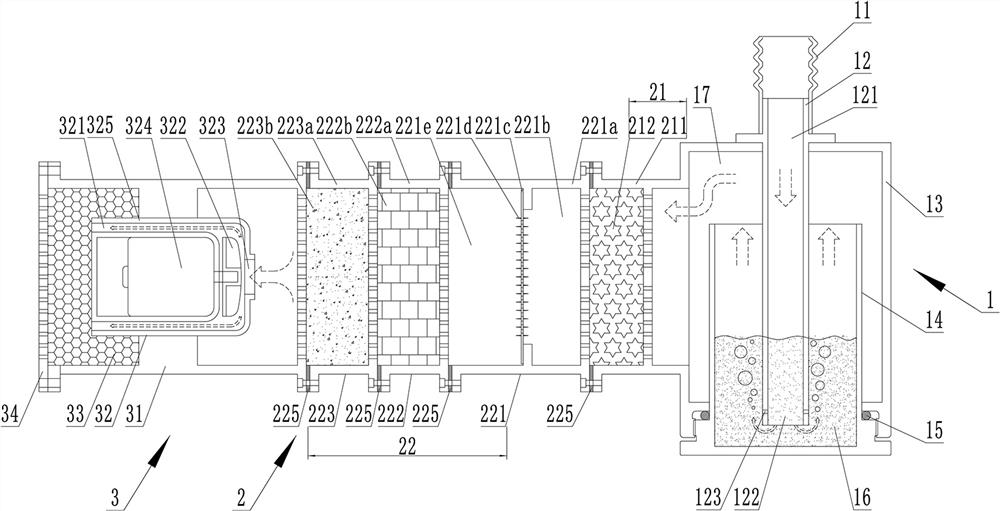

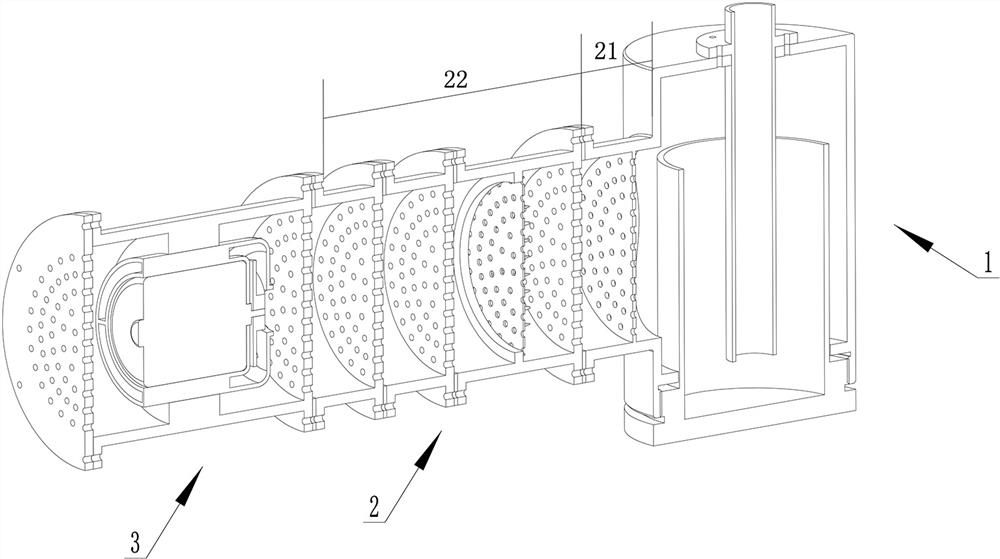

Moxibustion ash-removing smoke-removing purification device

PendingCN112387056AKeep the air cleanRealize harmless treatmentCombination devicesUsing liquid separation agentActivated carbon filtrationDust control

A moxibustion ash-removing smoke-removing purification device comprises an air inlet assembly (1), a filter assembly (2) and an exhaust assembly (3), and is characterized in that the air inlet assembly (1) comprises an inner cylinder (14), an outer cylinder (13) arranged on the inner cylinder (14) in a sealed mode and a communicating pipe (12) fixed to the outer cylinder (13) and used for communicating the inner cylinder (14) to the outside; a filter cavity (17) is formed between the outer cylinder (13) and the inner cylinder (14); the filtering assembly (2) comprises a rough filtering assembly (21) and a fine filtering assembly (22); an electrostatic filtering assembly (221) comprises a metal pore plate (221c) limited in an electrostatic filtering shell (221a), a plurality of spray points(221e) distributed on the metal pore plate (221c), and a dust removal chamber (221b) and a buffer chamber (221d) which are separated by the metal pore plate (221c); and refined filtration cotton (222b) and activated carbon (223b) are respectivelyused forfiltering ina first-stage refined filtration assembly (222) and a second-stage refined filtration assembly (223). The moxibustion ash-removing smoke-removing purification device has the advantages of simple and compact structure, good purification effect, safety and stability in operation, low operation noise, easiness in maintenance and the like.

Owner:沈阳天仁合一科技有限公司

Clean operation shelter

ActiveCN102409873BEasy to carry outBig spaceLighting and heating apparatusHospitalsConstant forceAir cleaning

Owner:CHONGQING ENDURANCE IND +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com