Winding type composite core pultrusion impregnation process for smart energy and special impregnation apparatus therefor

A smart energy, winding technology, applied in electrical components, circuits, cables/conductors, etc., can solve the problems of complex tooling and slow research and development, and achieve the effect of high winding efficiency, simple structure and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

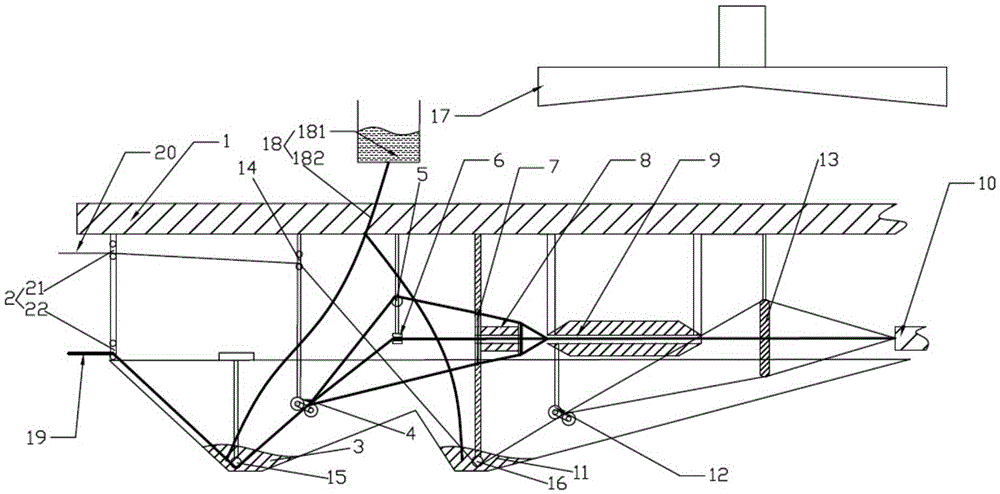

[0026] See figure 1 , a winding-type composite core pultrusion impregnation device for smart energy in this embodiment includes a first yarn dividing frame 2 arranged on a tooling support 1, a first impregnation tank 3, a first extrusion roller 4, a first Two-point creel 5, rubber scraper 6, first yarn collector 7, winder 8, pre-curing mold 9, curing mold 10, second dipping tank 11, second extrusion roller 12, second yarn collector 13. The third creel 14, the first pressing roller 15, the second pressing roller 16, the exhaust fan 17 and the resin feeding system 18. The upper and lower ends of the first yarn divider frame 2 are respectively provided with an upper yarn divider 21 and a lower yarn divider 22; the first extrusion roller 4 and the second extrusion roller 12 are respectively arranged in the first dipping tank 3 and the second dipping tank 11; the second yarn dividing frame 5 and the rubber scraper 6 are arranged at the front of the first yarn collector 7; the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com