Environment-friendly toilet paper processing method

A processing method and technology of toilet paper, applied in pulp beating/refining method, special paper, paper, etc., can solve problems affecting environmental sanitation and human health, bacterial pollution of toilet paper, affecting human health, etc., so that it is not easy to be contaminated by bacteria, Good environmental protection, simple and convenient preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

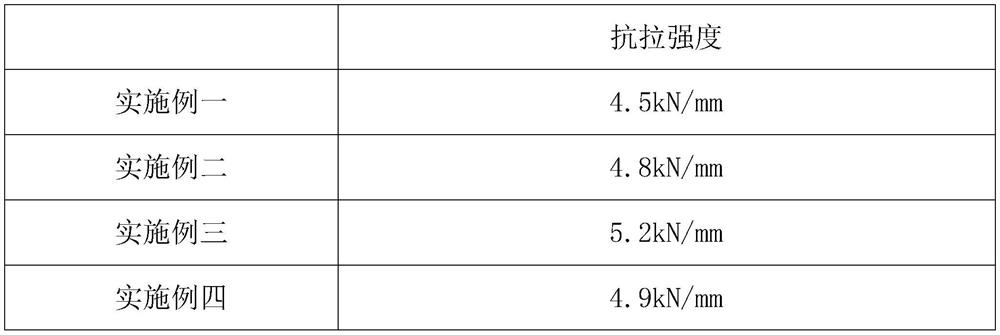

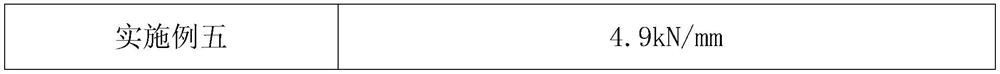

Examples

Embodiment 1

[0024] A processing method for environmentally friendly toilet paper, comprising the following steps:

[0025] S1: Pulping: Put the large shaft paper into the pulverizer for pulverization, add an appropriate amount of water during the pulverization process to obtain a slurry;

[0026] S2: Refining: adding the slurry into the grinding machine for refining treatment, grinding the slurry evenly, and gradually adding an appropriate amount of nitrifying bacteria during the grinding process;

[0027] S3: Drying: Add the slurry to the dryer for drying until the moisture is completely removed to obtain semi-finished toilet paper;

[0028] S4: Rewinding and cutting: rewinding and cutting the semi-finished toilet paper;

[0029] S5: heat sterilization: add the semi-finished toilet paper that has been rewinded and cut into the heating furnace for sterilization;

[0030] S6: Packaging: packaging semi-finished toilet paper to obtain finished toilet paper.

[0031] In this embodiment, in...

Embodiment 2

[0033] A processing method for environmentally friendly toilet paper, comprising the following steps:

[0034] S1: Pulping: Put the large shaft paper into the pulverizer for pulverization, add an appropriate amount of water during the pulverization process to obtain a slurry;

[0035] S2: Refining: adding the slurry into the grinding machine for refining treatment, grinding the slurry evenly, and gradually adding an appropriate amount of nitrifying bacteria during the grinding process;

[0036] S3: Drying: Add the slurry to the dryer for drying until the moisture is completely removed to obtain semi-finished toilet paper;

[0037] S4: Rewinding and cutting: rewinding and cutting the semi-finished toilet paper;

[0038] S5: heat sterilization: add the semi-finished toilet paper that has been rewinded and cut into the heating furnace for sterilization;

[0039] S6: Packaging: packaging semi-finished toilet paper to obtain finished toilet paper.

[0040] In this embodiment, in...

Embodiment 3

[0042] A processing method for environmentally friendly toilet paper, comprising the following steps:

[0043] S1: Pulping: Put the large shaft paper into the pulverizer for pulverization, add an appropriate amount of water during the pulverization process to obtain a slurry;

[0044] S2: Refining: adding the slurry into the grinding machine for refining treatment, grinding the slurry evenly, and gradually adding an appropriate amount of nitrifying bacteria during the grinding process;

[0045] S3: Drying: Add the slurry to the dryer for drying until the moisture is completely removed to obtain semi-finished toilet paper;

[0046] S4: Rewinding and cutting: rewinding and cutting the semi-finished toilet paper;

[0047] S5: heat sterilization: add the semi-finished toilet paper that has been rewinded and cut into the heating furnace for sterilization;

[0048] S6: Packaging: packaging semi-finished toilet paper to obtain finished toilet paper.

[0049] In this embodiment, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com