Device for performing singeing process on textile

A technology for textiles and crafts, which is applied in the field of singeing devices for textiles, which can solve problems such as high energy consumption, high risk of singeing, and unsatisfactory waste gas treatment, so as to increase device safety, ensure health, and reduce textile fabrics. The effect of the risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

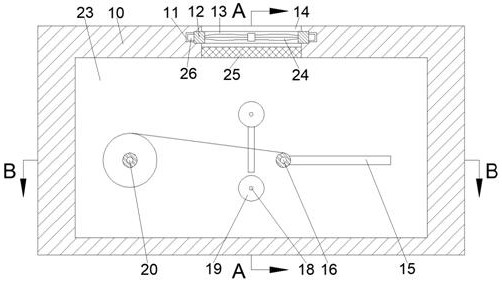

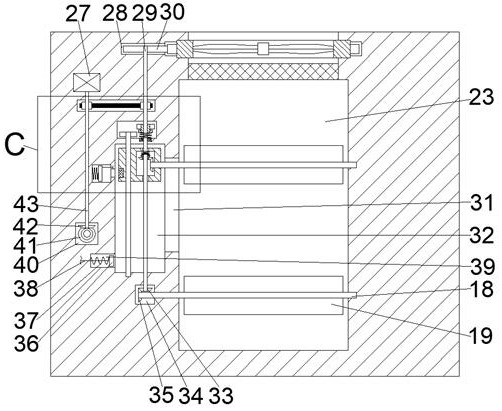

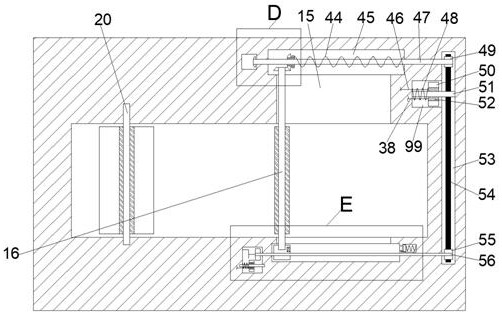

[0020] Combine below Figure 1-6 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0021] combined with Figure 1-6The described device for carrying out the singeing process for textiles comprises a main box 10, the main box 10 is provided with a singeing chamber 23, and the upper side of the singeing chamber 23 is communicated with a ventilation chamber 14, so An exhaust gas filter 25 is fixedly connected to the inner wall of the ventilation cavity 14, and a fan seat 12 located on the upper side of the exhaust filter 25 is connected to the inner wall of the ventilation cavity 14 in rotation. Fan cavity 13, fan 24 is fixedly connected on the inner wall of the fan cavity 13, the outer side of the fan base 12 is provided with an annular rack cavity 11 with the fan ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com