Electric vehicle packaging automatic sorting and conveying line

An automatic sorting and electric vehicle technology, applied in the direction of sorting, static electricity, electrical components, etc., can solve the problems of lack of dust removal and temperature and humidity monitoring, and low sorting efficiency of sorting conveyor lines, and achieve the effect of keeping the air clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

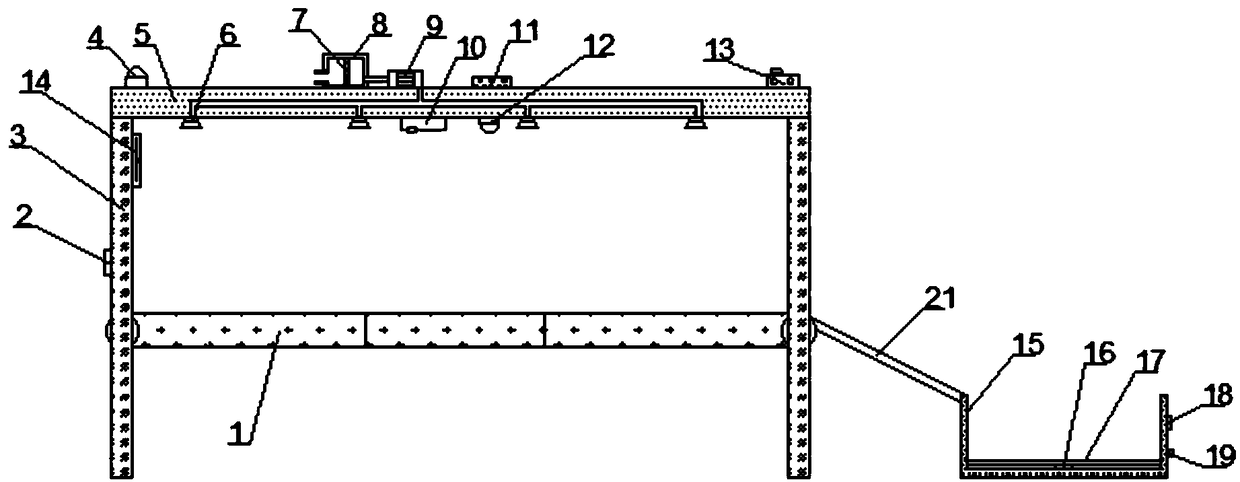

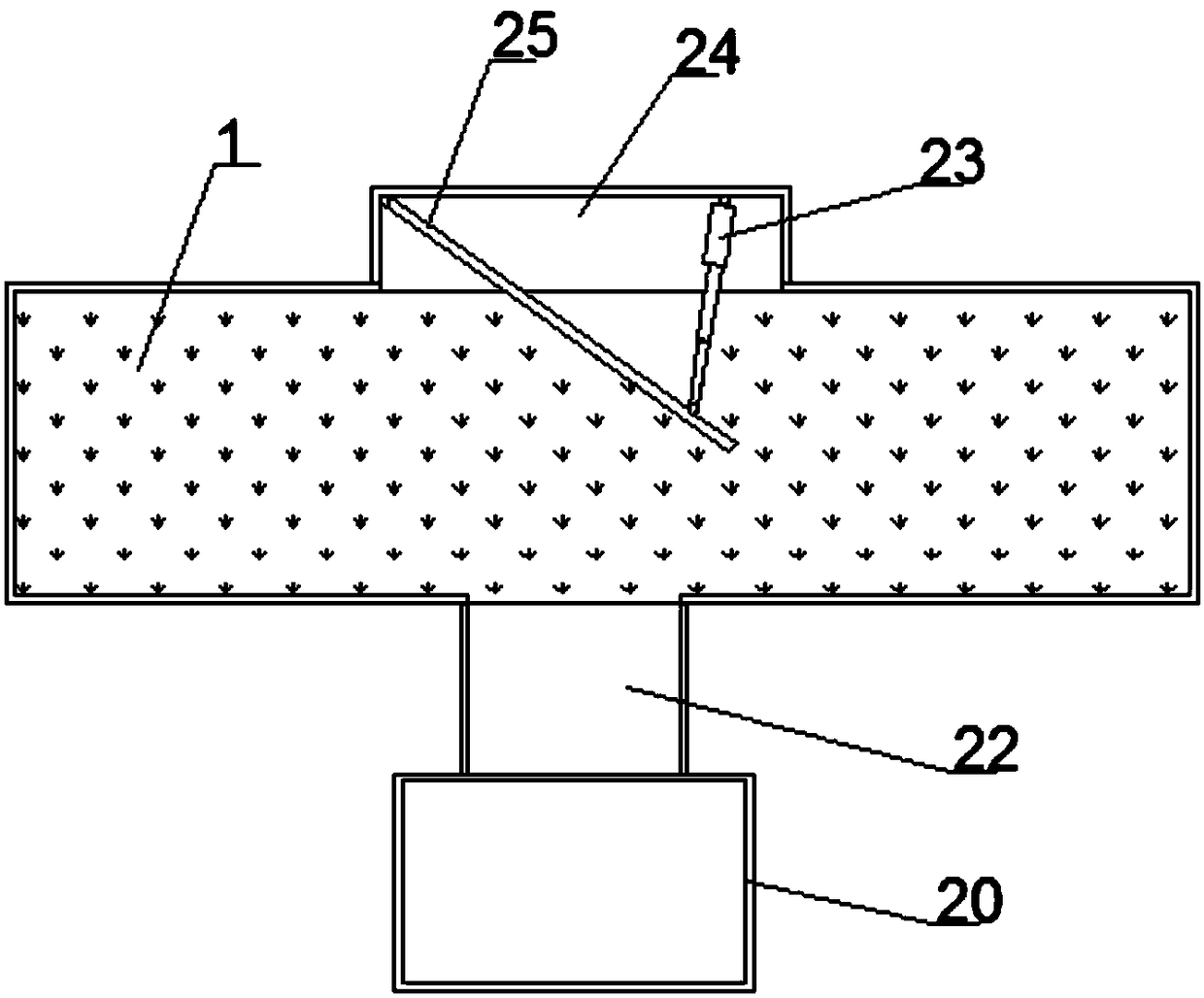

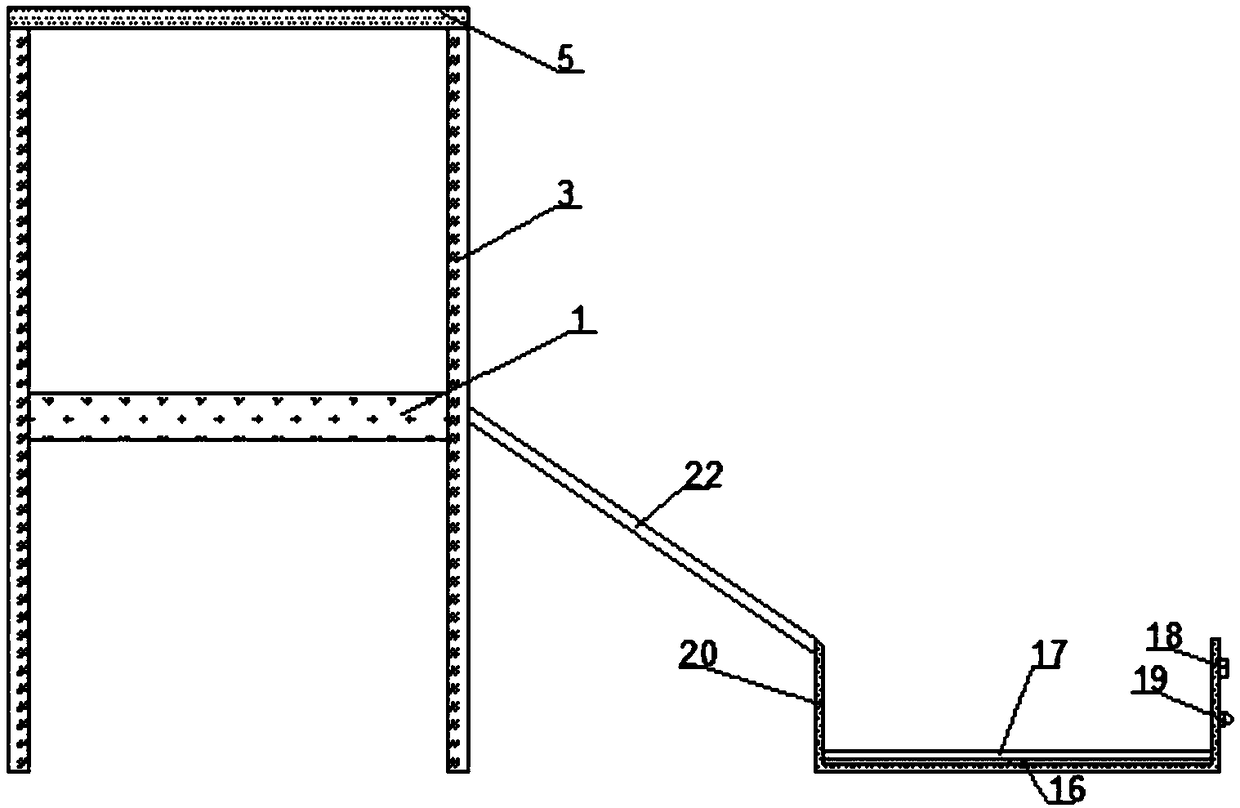

[0024] Such as Figure 1-4 As shown, an electric vehicle packaging automatic sorting conveyor line includes a conveyor belt body 1, a support rod 3 and a No. 1 collection box 15, and a conveyor belt body 1 is installed between the support rods 3 through bolts, and the conveyor belt One side of the main body 1 is provided with a fixed groove 24, and the other side of the conveyor belt body 1 is provided with a No. 1 inclined plate 22, the inner side of the fixed groove 24 is connected to the rotating plate 25 through a rotating shaft, and one side of the rotating plate 25 is connected through a rotating shaft Electric telescopic rod 23, the bottom end of the No. 1 inclined plate 22 is connected to the No. 1 collection box 20, one end of the conveyor belt body 1 is provided with a No. 2 inclined plate 21, and the bottom end of the No. 2 inclined plate 21 is connected to the No. 2 collection box 15. The No. 1 collection box 20 and the No. 2 collection box 15 are both provided wit...

Embodiment 2

[0038] Such as Figure 1-4 As shown, an electric vehicle packaging automatic sorting conveyor line includes a conveyor belt body 1, a support rod 3 and a No. 1 collection box 15, and a conveyor belt body 1 is installed between the support rods 3 through bolts, and the conveyor belt One side of the main body 1 is provided with a fixed groove 24, and the other side of the conveyor belt body 1 is provided with a No. 1 inclined plate 22, the inner side of the fixed groove 24 is connected to the rotating plate 25 through a rotating shaft, and one side of the rotating plate 25 is connected through a rotating shaft Electric telescopic rod 23, the bottom end of the No. 1 inclined plate 22 is connected to the No. 1 collection box 20, one end of the conveyor belt body 1 is provided with a No. 2 inclined plate 21, and the bottom end of the No. 2 inclined plate 21 is connected to the No. 2 collection box 15. The No. 1 collection box 20 and the No. 2 collection box 15 are both provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com