Gel-anion-bamboo charcoal composite latex sponge and manufacturing method thereof

A technology of compounding latex and gel sponge, applied in chemical instruments and methods, rubber layered products, layered products, etc., to achieve the effects of regulating human body functions, improving air permeability and adsorption, and soft touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

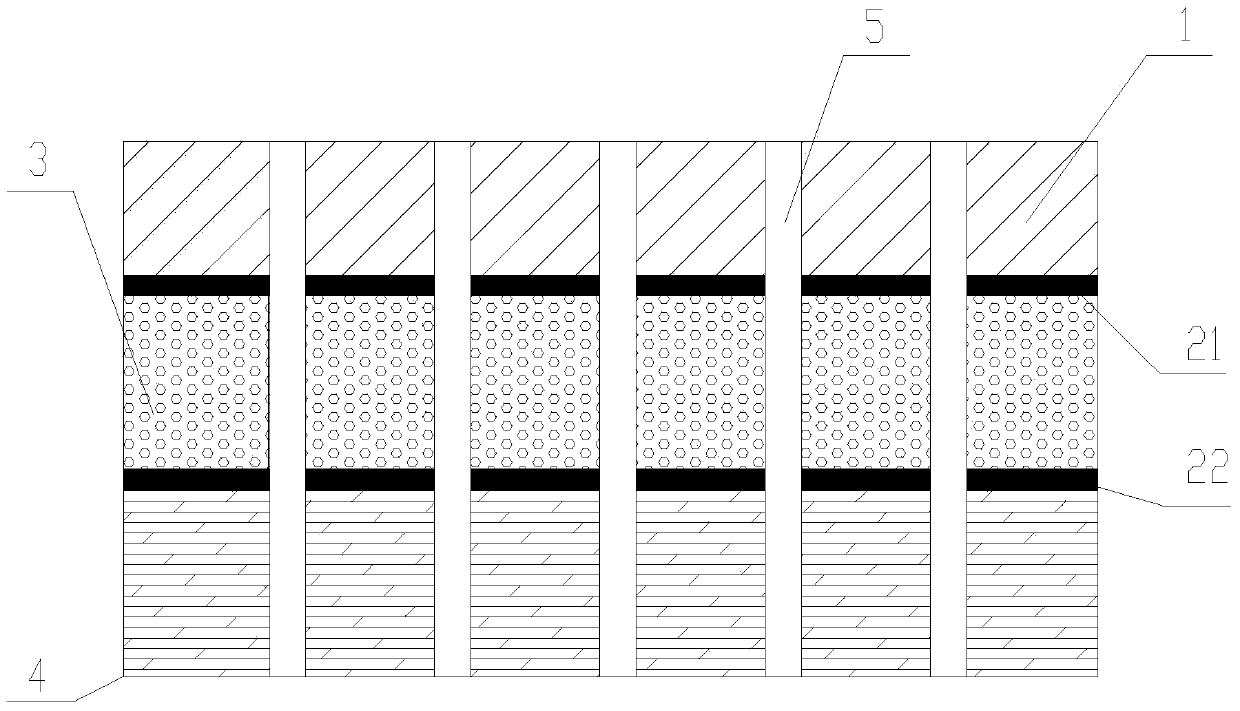

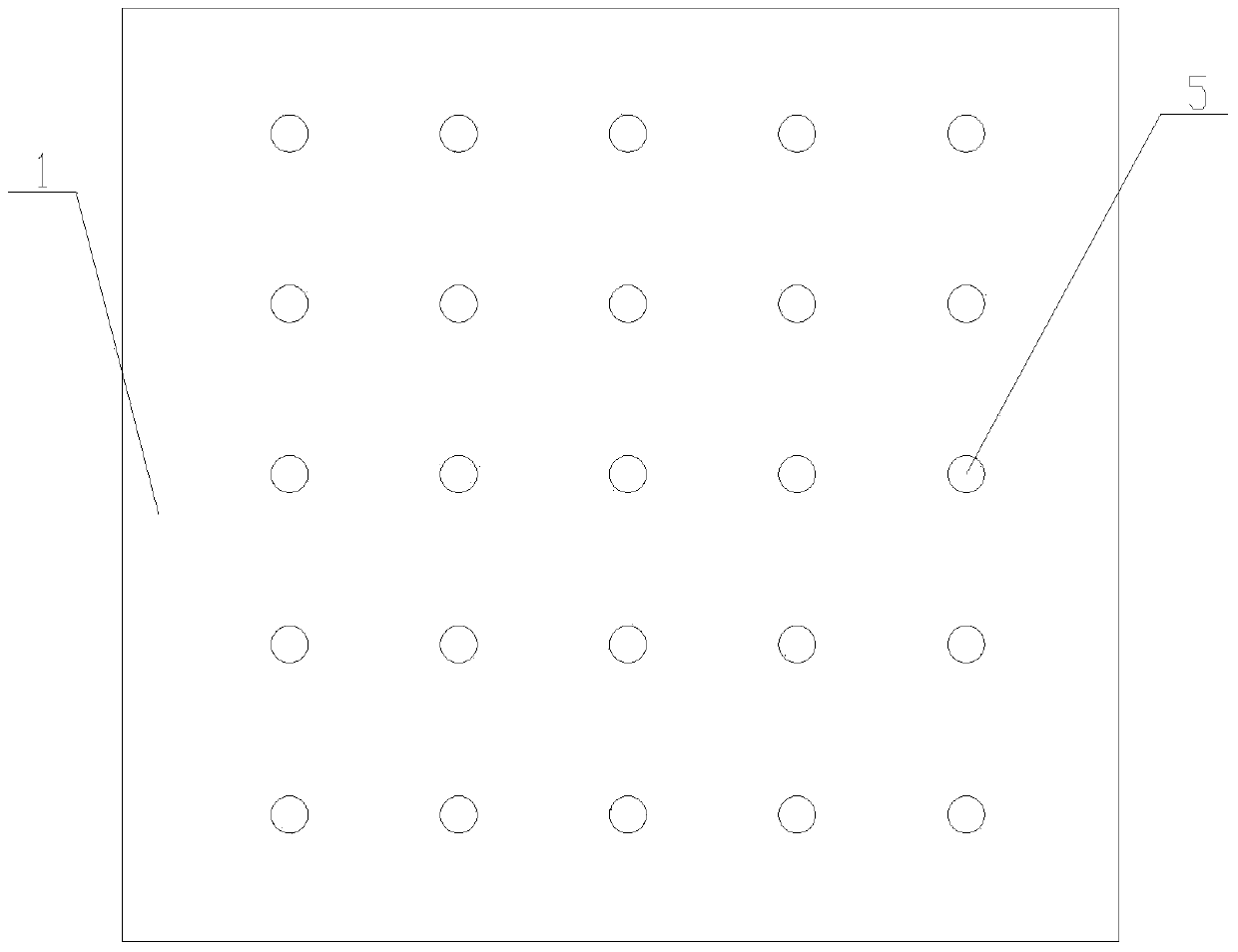

[0019] The present invention as Figure 1~2 Shown, comprise gel sponge layer 1, negative ion sponge layer 3 and bamboo charcoal sponge layer 4, be connected by natural cross-linking agent layer-21 between gel sponge layer 1 and negative ion sponge layer 3, described negative ion sponge layer 3 and bamboo charcoal The sponge layer 4 is connected by a natural cross-linking agent layer two 22; the gel sponge layer 1, the anion sponge layer 3 and the bamboo charcoal sponge layer 4 form an integral body;

[0020] The gel sponge layer 1 includes the following components by weight: 100 parts of natural latex, 3-8 parts of gel, 1-9 parts of sulfur, 1-6 parts of zinc oxide, 1-5 parts of accelerator, fluorosilicone 0.5~2 parts of sodium ricinoleate, 0.1~2 parts of potassium ricinoleate;

[0021] The negative ion sponge layer 3 includes the following components by weight: 100 parts of natural latex, 2 to 5 parts of negative ion powder, 1 to 9 parts of sulfur, 1 to 6 parts of zinc oxide,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com