Micro-positive pressure dust isolation system

A technology of dust isolation and micro-positive pressure, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as safety production and occupational health and safety hazards, production safety hazards, equipment failures, etc., to prevent dust from entering Equipment cab, reducing the workload of equipment maintenance, and maintaining the effect of air environment sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

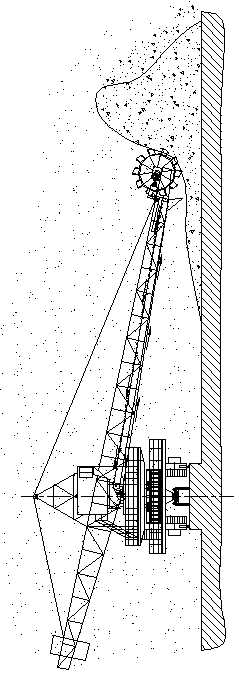

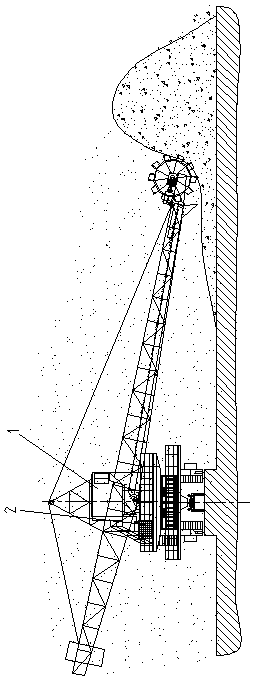

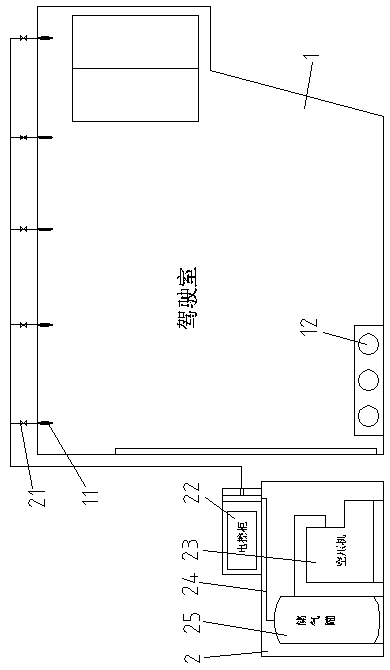

[0020] As shown in the figure, a micro-positive pressure dust isolation system includes an equipment platform with a cab installed, and an air treatment package 2 with air filtration, storage and pressure regulation functions is installed on the equipment platform behind the cab 1, and the air The complete treatment device 2 is connected to the top of the cab 1 through the air duct 24. The air duct 24 is located above the cab 1 and is provided with a plurality of air inlets 11. The air duct 24 can pass through the air inlet 11 and the inner space of the cab 1. Connected, the cab 1 is provided with an exhaust port 12 near the door, and the interior space of the cab 1 communicates with the external space through the exhaust port 12; the complete set of air treatment device 2 includes an isolation box, and the sealed casing of the isolation box is installed inside There is an air storage tank 25, and the connection between the top of the air storage tank 25 and the ventilation pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com