Garbage dehydration solid-liquid separation device

A technology of solid-liquid separation and garbage dehydration, applied in the direction of stamping machines, presses, manufacturing tools, etc., can solve the problem of boxes, paper, chopsticks, cutting boards, broken kitchen knives, torn clothes, ropes and even pickle jars, Table legs and chair legs, the system cannot operate normally and stably, and the collection situation is not ideal, etc., to achieve the effect of improving operating efficiency, good force, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following embodiments.

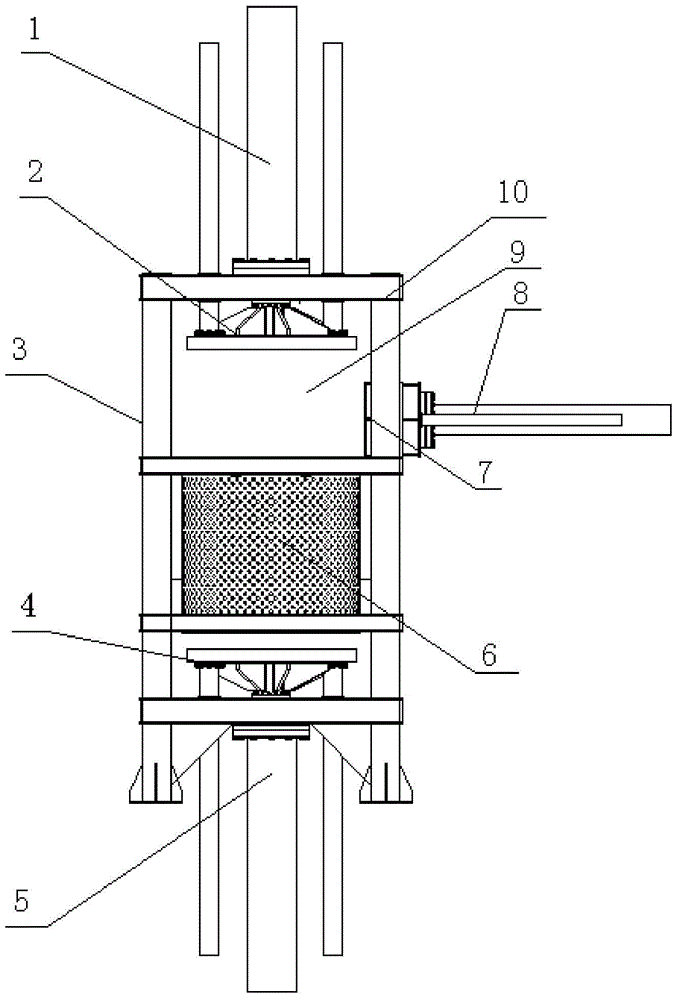

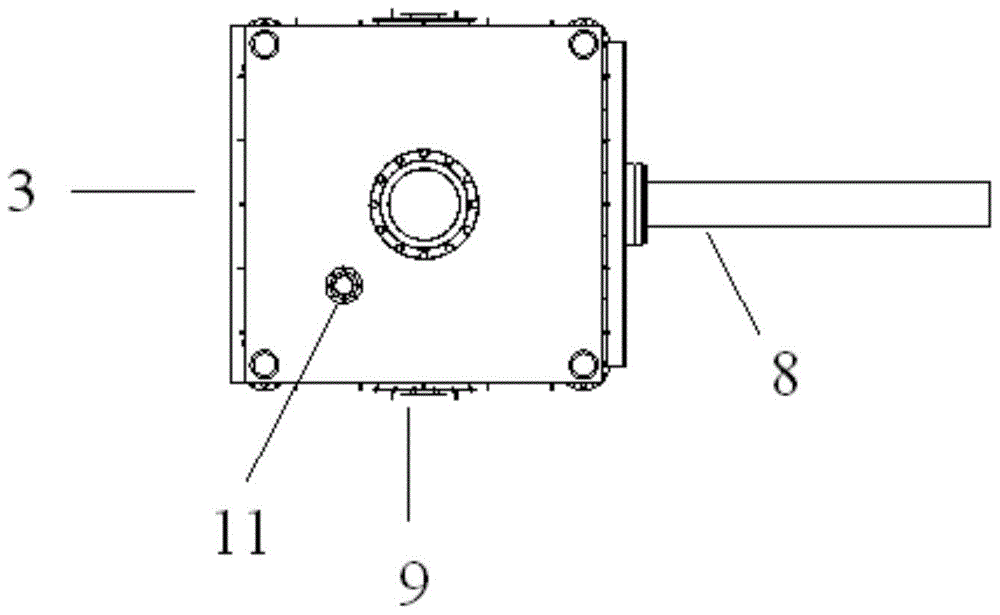

[0039] like figure 1 and figure 2Shown, is the garbage dehydration solid-liquid separation device of the present invention, comprises airtight solid-liquid separation cylinder body (not shown in the figure), has the descending hydraulic system 1 of lower push plate 2, has the material discharge of push plate 7. Hydraulic system 8 and the ascending hydraulic system 5 that has upper push plate 4; 4 sets of beams (not marked in the figure) connected to the column in sequence from top to bottom; a pressing cylinder 6 is installed in the lower inner cavity of the solid-liquid separation cylinder, and the pressing cylinder 6 is a cylinder with both top and bottom openings ; The upper push plate 4 is located in the squeeze cylinder 6, and is sealed with the bottom of the squeeze cylinder 6, and can move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com