Device and method for clearing manure of large-scale rabbit farm

A technology for removing manure and equipment, applied in the field of rabbit breeding, can solve the problems of not being able to use fertilizers, troublesome replacement of ropes, causing respiratory diseases, etc., and achieve the effects of reducing the occurrence of harmful gases, reducing maintenance costs, and reducing the volatilization area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The large-scale rabbit farm excrement cleaning equipment and method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

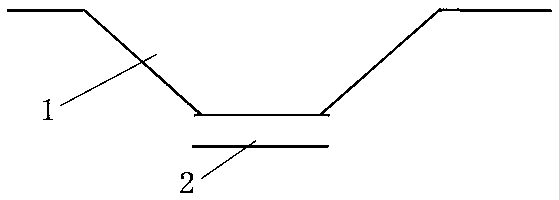

[0024] Such as figure 1 As shown, the large-scale rabbit field cleaning equipment of the present invention comprises dung ditch 1, and dung ditch 1 is a V-shaped cement structure, and the slope is 45 degrees, and the width is constant. The specific width is determined according to the width of the cage. The cement is ground smooth, with no water as the standard. The bottom of manure ditch 1 is equipped with conveyer belt 2, and the width of conveyer belt 2 is 30 or 40 centimetres, and the manure ditch edge on conveyer belt both sides is above conveyer belt. The conveyor belt 2 is connected with the motor, and the motor is connected with a timing switch. The opening time of the conveyor belt is controlled by the set time, and the conveyor belt is run regularly to clean up the fece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com