Safe and return dust-less dust exhaust apparatus for lapper

A technology of dust collection device and lapping machine, which is applied in mechanical cleaning, textile and paper making, high-pressure cleaning, etc., and can solve problems such as high density, dust return, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

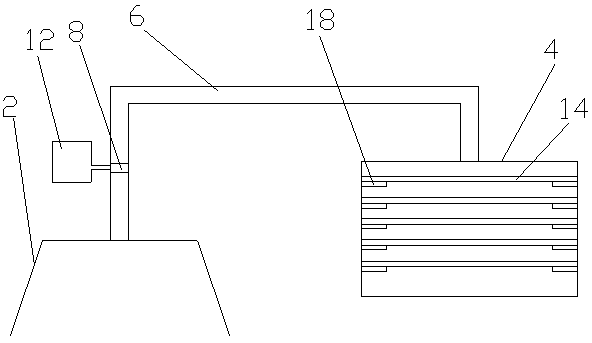

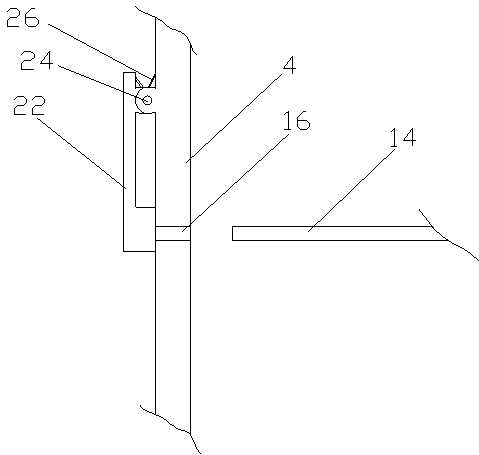

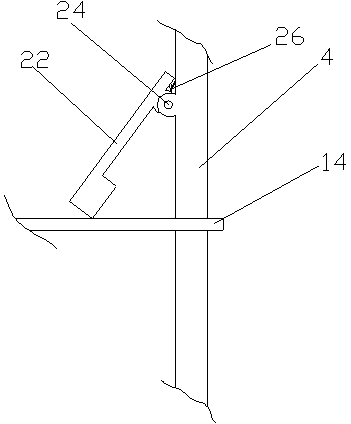

[0015] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0016] Such as Figure 1-3 As shown, a safe and less dust-returning dust collection device for a lap machine includes a bucket-shaped dust collection hood 2, a dust filter device, and a dust collection pipe 6 connecting the dust collection cover 2 and the dust filter device. One end of the dust collection cover 2 has a large opening, and the other end has a small opening, and the small end of the opening communicates with the dust collecting pipe 6 . In the dust collecting pipe 6, a suction fan 8 is provided, and the suction fan 8 has a motor speed regulating device 12, by which the suction fan 8 can be changed. The dust filter device includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com