A method for placing a vacuum glass support

A technology for vacuum glass and supports, applied in the field of laying vacuum glass supports, can solve the problems of reduced production efficiency, low support efficiency, single function, etc., and achieves the solution of unsmooth airflow, scientific and reasonable design, and simple overall structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: a kind of laying method of vacuum glass support, the steps are:

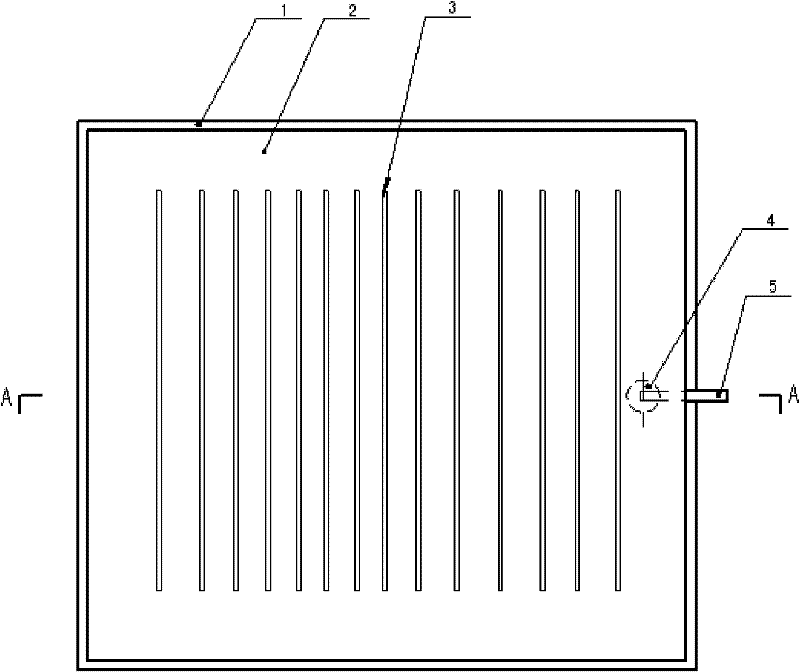

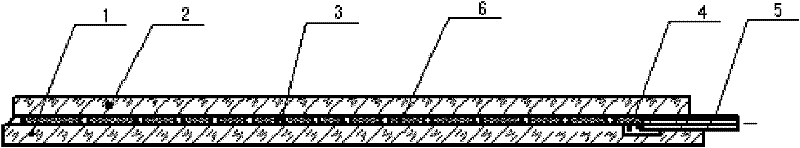

[0022] (1) Cut the upper glass 2 and the substrate glass 1 into substantially the same size. Generally, the upper glass is slightly smaller than the substrate glass, and then a suction groove 4 is made on one side of the substrate glass, and then sprayed, Apply a layer of adhesive 6 on the substrate glass by shower coating or brush coating to form an adhesive film layer. The adhesive is made of glass heat insulating material, and the glass heat insulating coating is an organic coating, such as polymer or resin, etc. , including inorganic coatings such as metal oxides and inorganic salts. For example, the glass heat insulation coating is made of urethane or resin high-temperature resistant organic glass coatings that can withstand high temperatures above 200 ° C, such as the alkyd produced by Shenzhen Dehou Technology Co., Ltd. Resin glass thermal insulation coating, the color of the coating ...

Embodiment 2

[0027] The difference from Example 1 is that the support wires or support rods arranged in parallel and uniform intervals are prefabricated in the support film layer in the glass heat insulation material, and the support film layer is directly placed between the upper glass and the substrate glass. Can.

[0028] Others are the same as in Example 1.

Embodiment 3

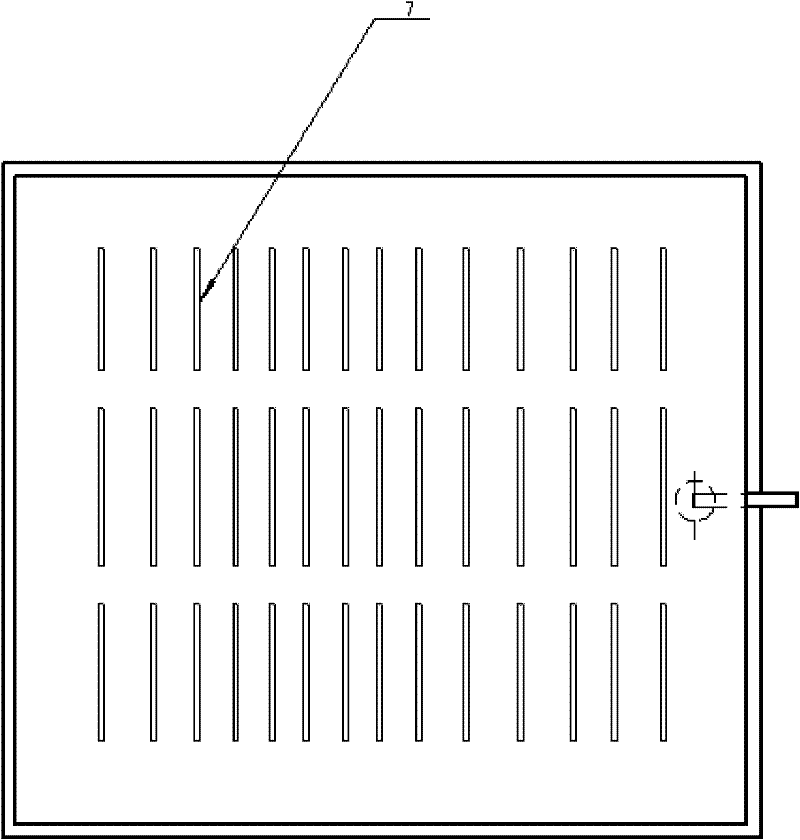

[0030] The difference from Embodiments 1 and 2 is that the support rods and support wires 7 are made intermittently, thereby improving the pumping efficiency.

[0031] Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com