Adsorption device of vacuum interlayer container

A technology of adsorption device and vacuum interlayer, which is applied to the installation device of container structure, the outer wall of container structure, the method of container discharge, etc. The effect of vacuum performance, improving performance and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

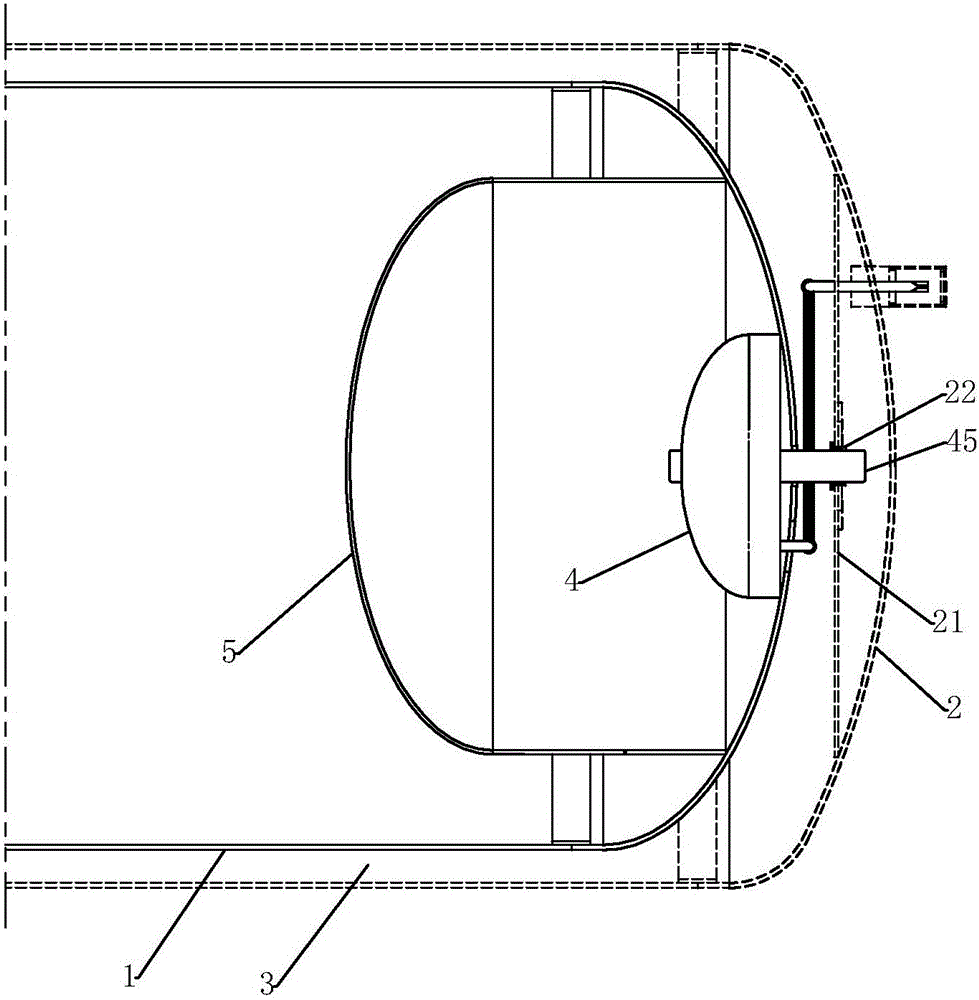

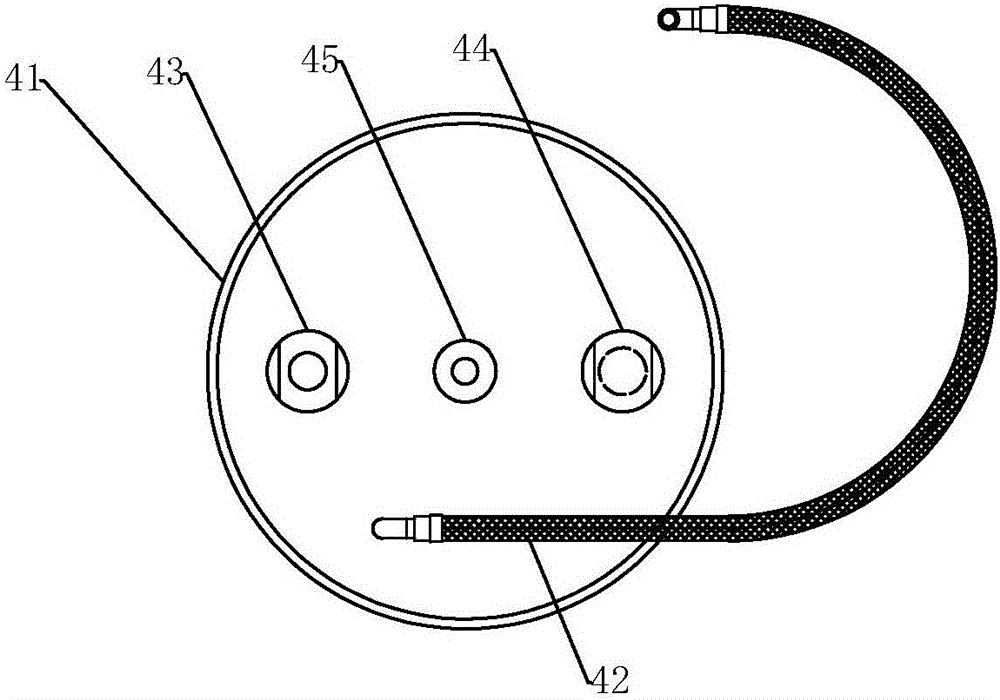

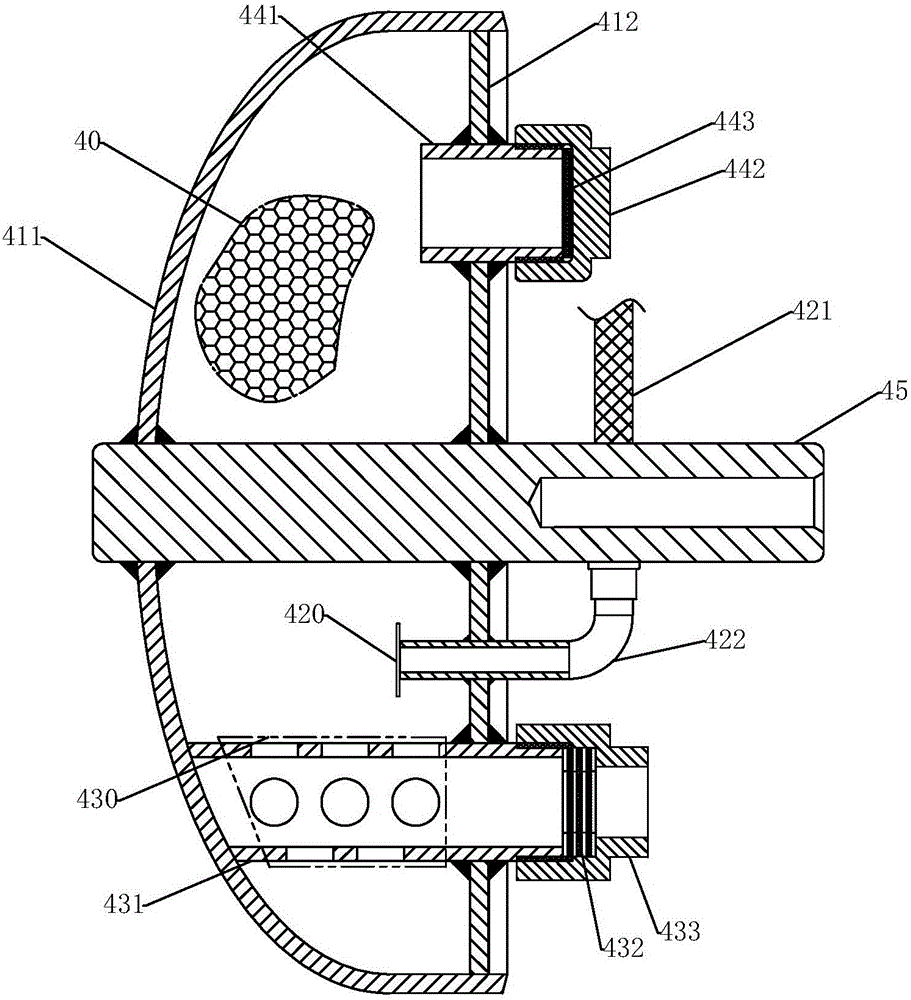

[0021] refer to Figure 1 to Figure 4 , a vacuum interlayer 3 container adsorption device of the present invention, comprising an inner container 1 and an outer container 2, an interlayer 3 is arranged between the inner container 1 and the outer container 2, and an adsorption chamber device 4 is connected to the inner container 1 , refer to figure 2 and image 3 , the adsorption chamber device 4 includes a cavity 41 , an air intake device 42 , a breaking device 43 and a filling device 44 .

[0022] The cavity 41 is welded by the cover body 411 and the sealing plate 412, and the cavity 41 is filled with an adsorbent 40, and the adsorbent 40 can be selected according to the type of gas leaked in the interlayer 3 to be adsorbed, preferably , the adsorbent 40 is a molecular sieve. In this embodiment, the cavity 41 is arranged inside the inner container 1, which can effectively reduce the thickness of the interlayer 3, and can place the cavity 41 filled with the adsorbent 40 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com