X-ray absorption grate manufacturing method and filling device thereof

An absorption grating and a manufacturing method are used in the manufacture of X-ray absorption gratings, metal-filled filling devices, and grating manufacturing equipment, which can solve the problems of high manufacturing cost, limited area, etc., and achieve convenient operation, uniform and dense filling, and device simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1. A method for manufacturing an X-ray absorption grating, comprising the following steps:

[0042] (1) Silicon-based production: select n-type or p-type silicon wafers and make a grating mask, and deposit a layer of Si on either surface of the silicon wafer 3 N 4 thin film, on Si 3 N 4 The film is coated with photoresist, and the pattern of the grating mask is photoetched onto the photoresist, and after developing and fixing, the Si at the specified position of the grating mask is sequentially removed. 3 N 4 thin film, and then remove the photoresist; then use photolithography to make a transparent electrode on the other surface of the silicon wafer to obtain a silicon base;

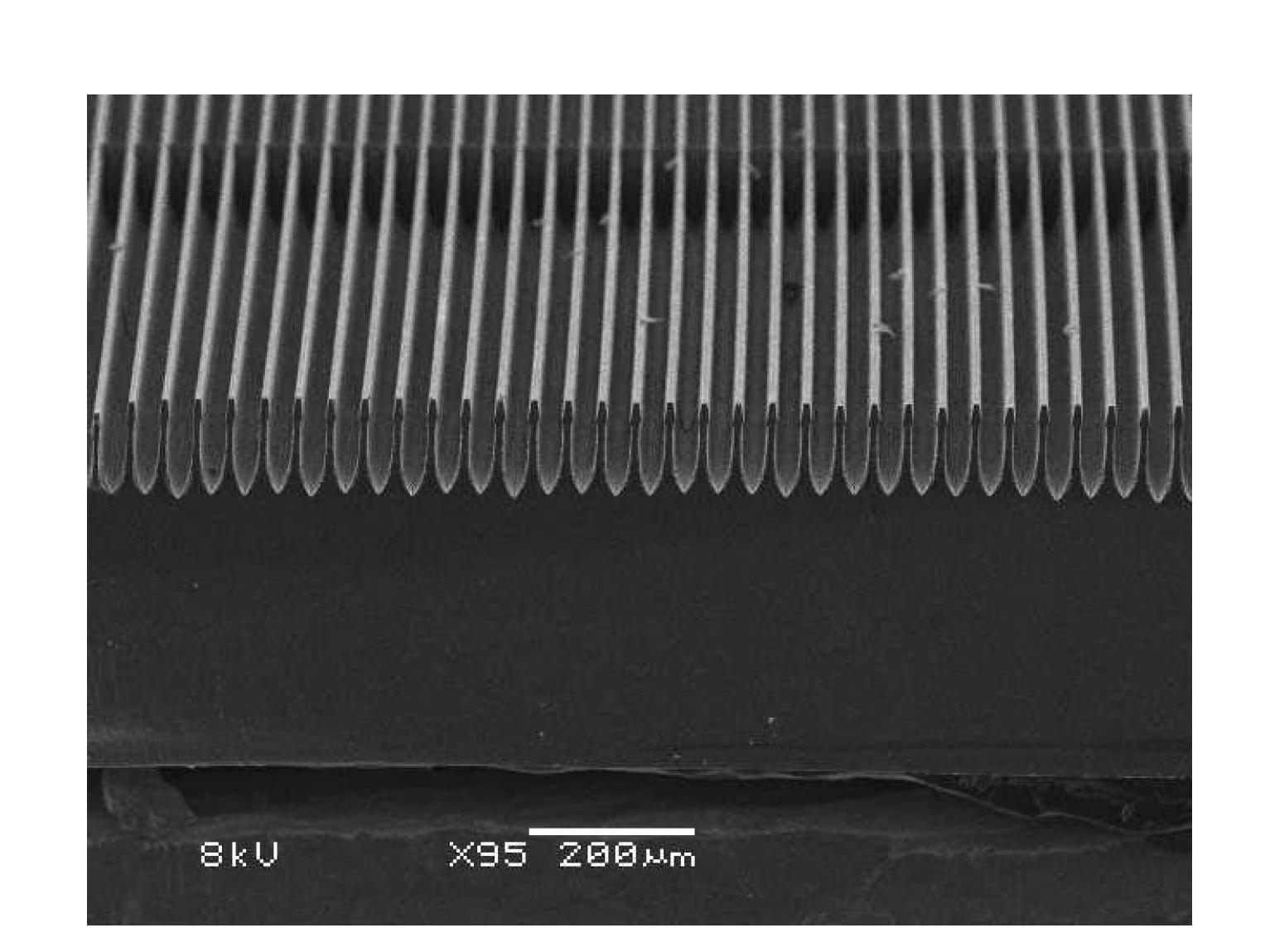

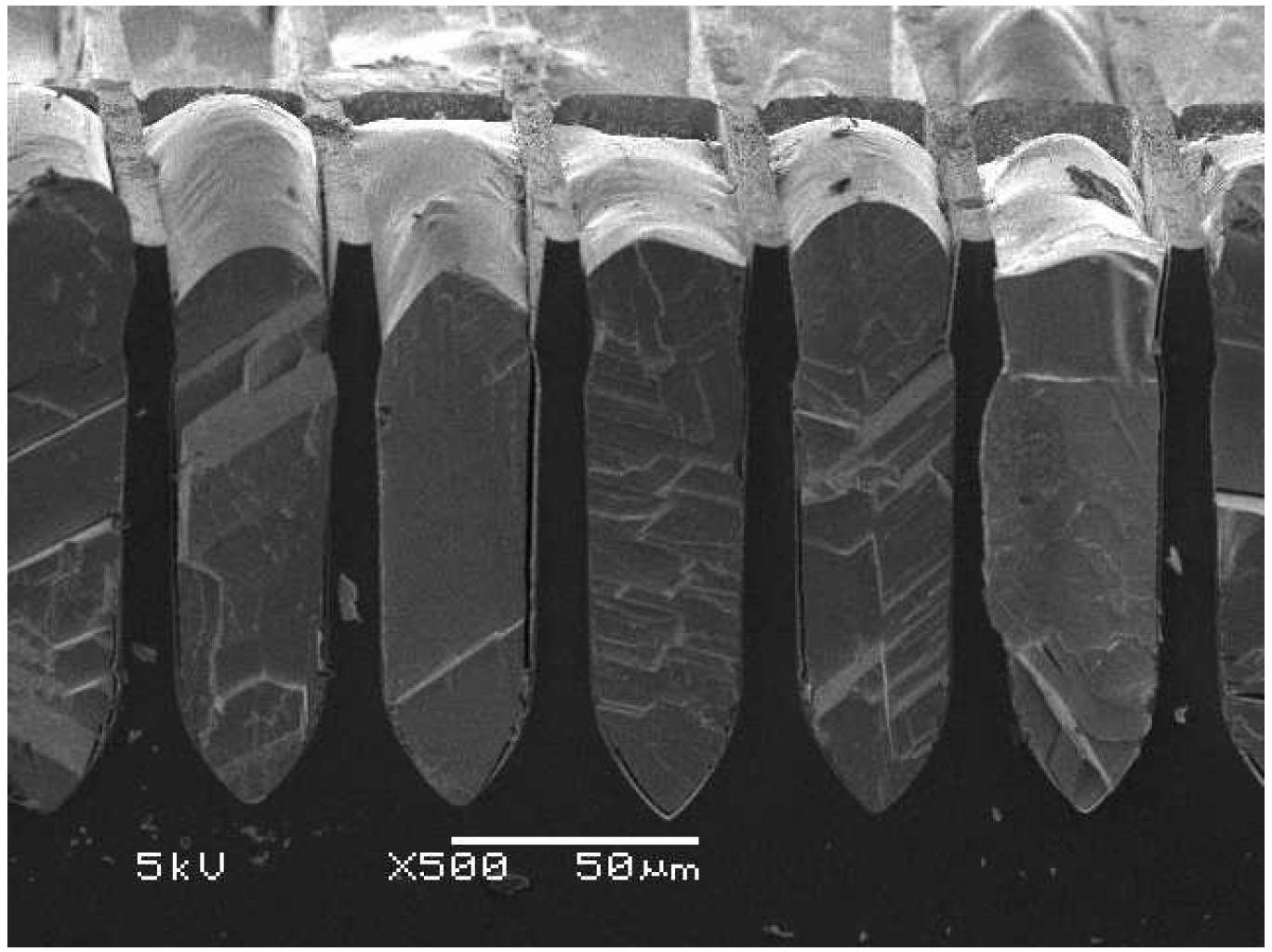

[0043] (2) Etch V-shaped grooves on the silicon base: protect the transparent electrode, and use an alkaline etching solution to anisotropically etch the silicon base, and do not cover Si in step (1) 3 N 4 V-shaped grooves are etched on the surface of the silicon base; the arrang...

Embodiment 2

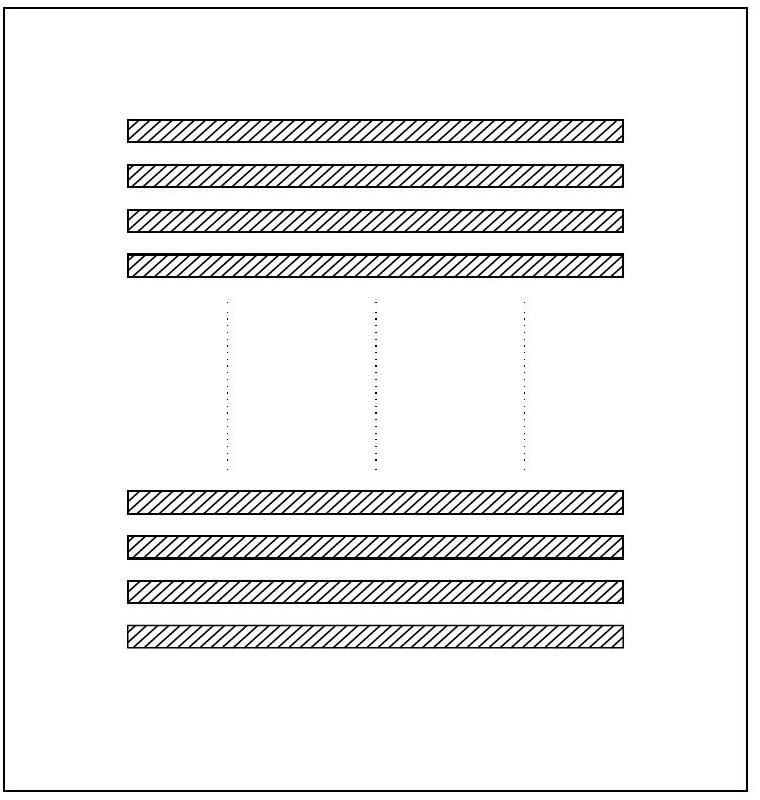

[0075] Embodiment 2, as Figure 6 As shown, the filling device used for metal filling in the manufacture of X-ray absorption gratings includes a sealed furnace body 1 with an inner cavity, a vacuum mechanism 71 for evacuating the sealed furnace body, and an inflation mechanism for inflating the sealed furnace body 61. The inner cavity of the sealed furnace body 1 is provided with a filling pool 2 with an open top for containing and melting heavy metals, a heating mechanism 3 for heating the filling pool 2, and a lifting device for moving the silicon base 100 in the inner cavity of the sealed furnace body. Pulling mechanism 4, the lower end of the pulling mechanism 4 is provided with a supporting mechanism 5 for fixing the silicon base 100, and the sealed furnace body 1 is provided with an air extraction nozzle 72 communicating with the inner cavity of the sealed furnace body 1. The exhaust nozzle 72 is connected with a vacuum mechanism 71, and the sealed furnace body 1 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com