Hydraulic suction seamless repair machine for car shell

A repairing machine and hydraulic mechanism technology, applied in the field of vehicle shell repairing equipment, can solve problems such as insufficient adhesion between suction cups and pits, unsatisfactory vehicle repair effects, and unsatisfactory pit suction effects, etc., achieving remarkable repair effects and wide application range Wider, improve the effect of covering and sealing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

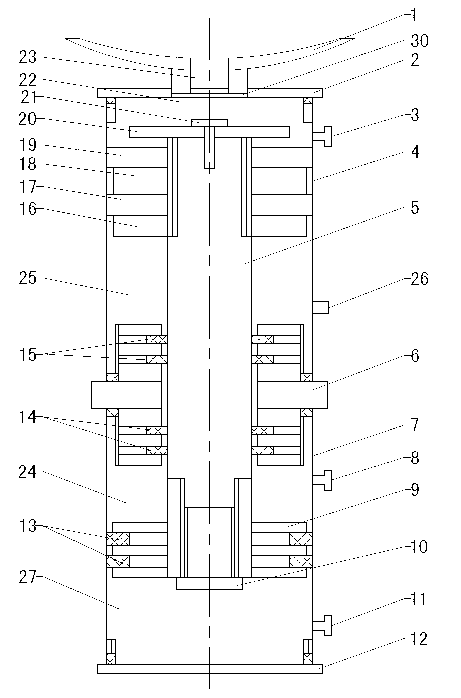

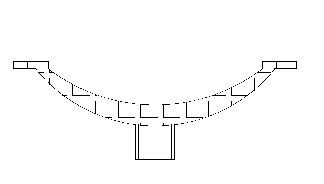

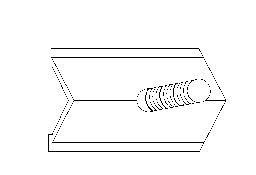

[0026] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~7 The present invention will be further described.

[0027] Refer to attached Figure 1~7 : The hydraulic suction non-mark repairing machine for the shell of a car, including a suction cup 1, a power mechanism and a water injection mechanism, which provides suction to the suction cup 1 through the power mechanism, and the bottom of the suction cup 1 is installed on the output end of the top of the power mechanism through the thread of the upper hydraulic cylinder end cover 2, so Disassemble and replace, and a sealing ring 30 is provided between the suction cup 1 and the upper hydraulic cylinder end cover 2; the power mechanism includes a piston rod 5 and an upper hydraulic mechanism and a lower hydraulic mechanism that are threaded up and down through a connecting piece 6, and the piston rod 5 Through the connecting piece 6, it runs through the upper hydraulic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com